Metal wire forming is the process of shaping metal wire into specific forms and structures using various techniques such as bending, cutting and welding. This manufacturing process is commonly used in industries such as automotive, aerospace and construction to create parts with precise dimensions and complex geometries. The process involves using specialized machinery and tools to shape the wire into the desired shape, ensuring high precision and consistency in the final product. Metal wire forming plays a vital role in the production of a wide range of products, from simple wire forms to complex and complex components, requiring a deep understanding of material properties, engineering principles and manufacturing techniques to achieve optimal results.

Features of Metal Wire Forming

- Material Versatility:

– Uses various metals like stainless steel, copper, and aluminum.

- Precision Manufacturing:

– Advanced CNC and automated processes ensure high accuracy.

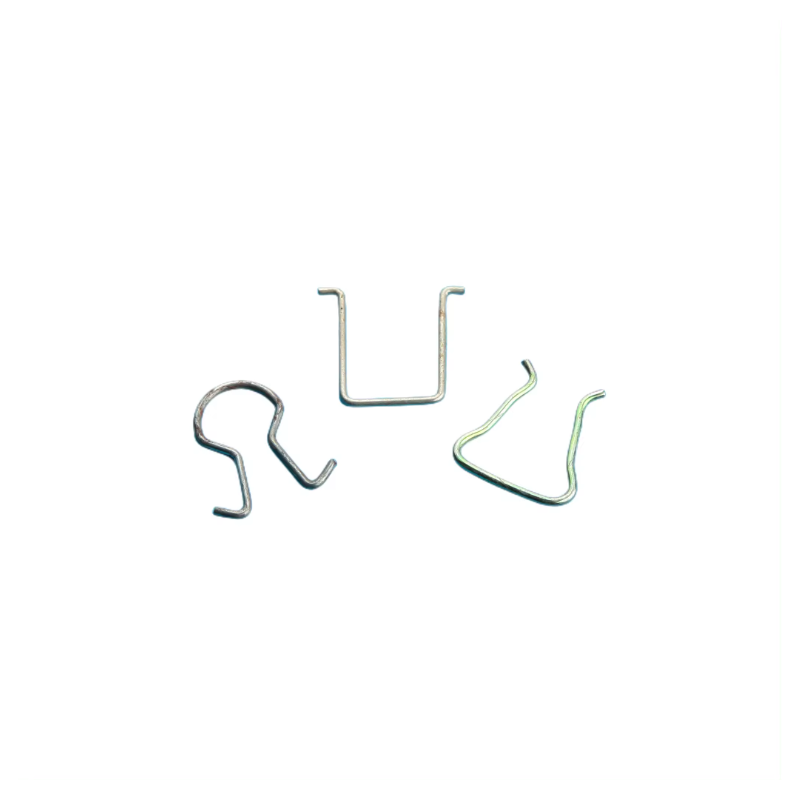

- Complex Geometries:

– Capable of producing intricate forms like coils, hooks, and springs.

- Custom Finishing:

– Offers electroplating, powder coating, and anodizing for durability and aesthetics.

- Wide Application Range:

– Suitable for automotive, aerospace, medical devices, and electronics.

- Quality Assurance:

– Adheres to strict quality control standards and certifications.

Our Advantages:

Good Quality Control

Ensures meticulous oversight at every stage of production to maintain high standards and product consistency.

Customizable Product Services

Tailors products to meet specific customer requirements, offering flexibility and personalized solutions.

Advanced Production Technology

Utilizes state-of-the-art manufacturing techniques and equipment to optimize efficiency and product quality.

Our Service:

Comprehensive Quality Management

Ensuring stringent quality control measures throughout the manufacturing process to uphold product excellence.

Cutting-Edge Manufacturing Techniques

Employing advanced technologies and methodologies to enhance efficiency and product innovation.

Seamless Communication Channels

Facilitating clear and efficient communication to address client needs and ensure smooth project execution.

Competitive Pricing Strategies

Offering highly competitive pricing structures without compromising on product quality or service standards.

Tailored Product Solutions

Providing customizable solutions to meet individual client specifications and preferences effectively.

Dynamic OEM and ODM Support

Delivering effective Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) services to accommodate diverse project requirements.

Reviews

There are no reviews yet.