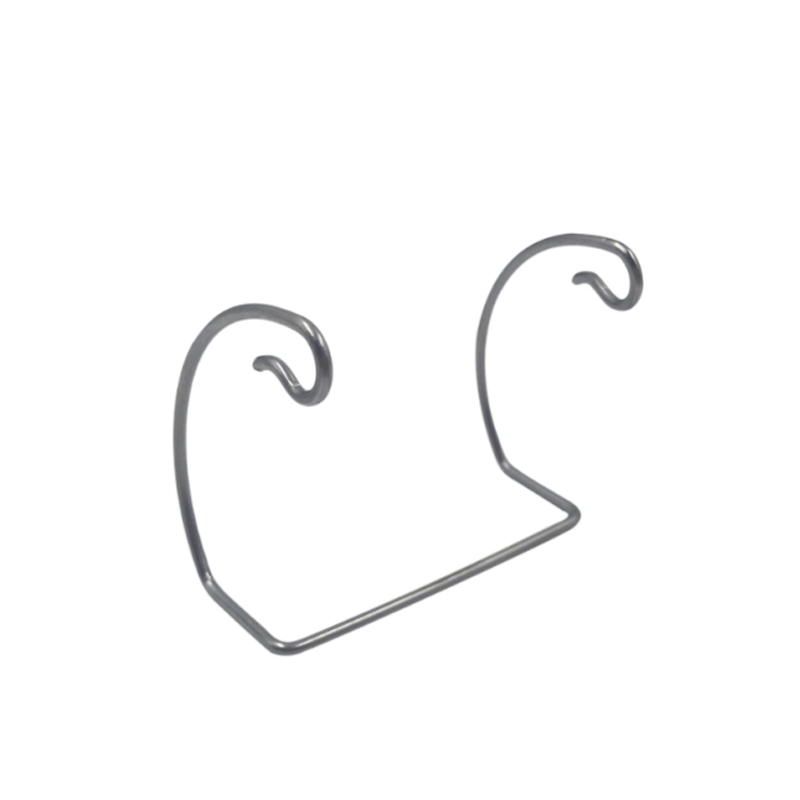

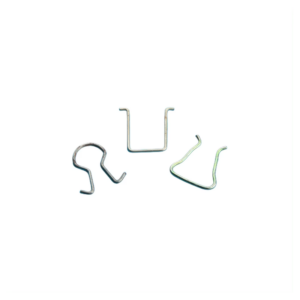

Personalized Stainless Steel Wire Forming for Engine Connectors

Details:

– Process: CNC Spring

– Application Field: Electronic spare parts, furniture parts, cellphone parts, auto hardware parts, gym equipment fittings, etc.

– Surface Treatments:

– Anodizing

– Polishing

– Powder Coating

– Passivation

– Sandblasting

– Nickel Plating

– Zinc Plating

– Chrome Plating

– Heat Treatment

– Oxidation

– Applications: Electronics, automotive, electric appliances, electrical machines, toys, medical devices, loudspeaker boxes, furniture, fitness equipment, and other industries.

– Design: Based on customer drawings or samples

– Equipment:

– CNC Spring Machines

– CNC Punching Machines

– CNC Milling Machines

– CNC Turning Machines

– CNC Machining Centers

– Automatic Lathes

– Linear Cutting Machines

– Grinding Machines

– Standards: JIS, DIN, ANSI, EN, etc.

– Tolerance: 0.005mm – 0.01mm

– Surface Roughness: Ra 1.6 – 3.2

– Software: AutoCAD, SolidWorks, UG (PDF, DWG, DXF, IGS, STEP, SLDPRT)

– Packaging: Foam polybag + outer standard carton box/carton box with pallet, stretch film

– Delivery: 10-25 days after receipt of customer’s deposit

– Main Markets: USA, UK, Spain, Germany, Italy, Switzerland, etc.

Our Comprehensive Services

-

Sustainable Profitability:

– We ensure profitability and sustainability even amidst economic challenges through strategic market diversification and a steadfast conservative business approach established since 1998.

-

Innovative Cost Reduction Solutions:

– We offer pioneering cost reduction options during the design phase, providing value-added, engineered cost savings for our customers’ existing products.

-

Customer-Centric Approach:

– We prioritize customer feedback and continuously enhance our systems, processes, and facilities to meet their evolving needs and requests effectively.

-

Continuous Improvement:

– We vigilantly monitor key performance indicators and implement proactive changes to consistently enhance our operational goals, striving for continuous improvement in all aspects of our business.

-

Commitment to Quality Excellence:

– Our unwavering commitment to quality is validated by third-party certification to the esteemed ISO/TS 16949:2002 standard. We offer unparalleled quality distinction in manufacturing, innovation, and engineering, catering to the global OEM market.

Ordering Procedure:

- Submission of Requirements:

– Provide drawings or samples for initial assessment.

- Project Evaluation:

– Conduct thorough assessment of the project requirements.

- Design Proposal:

– Present design options based on assessment findings.

- Design Approval:

– Review and approve the proposed design.

- Sample Production:

– Produce and send samples for your evaluation.

- Order Placement:

– Confirm sample approval and place order, paying a 30% deposit.

- Production Initiation:

– Commence production upon receipt of deposit.

- Product Completion:

– Upon completion, deliver the goods to Xiamen port.

- Final Payment:

– Pay the remaining balance after reviewing the Bill of Lading (B/L) copy.

- Order Completion:

– Order fulfillment completed, thank you!

Reviews

There are no reviews yet.