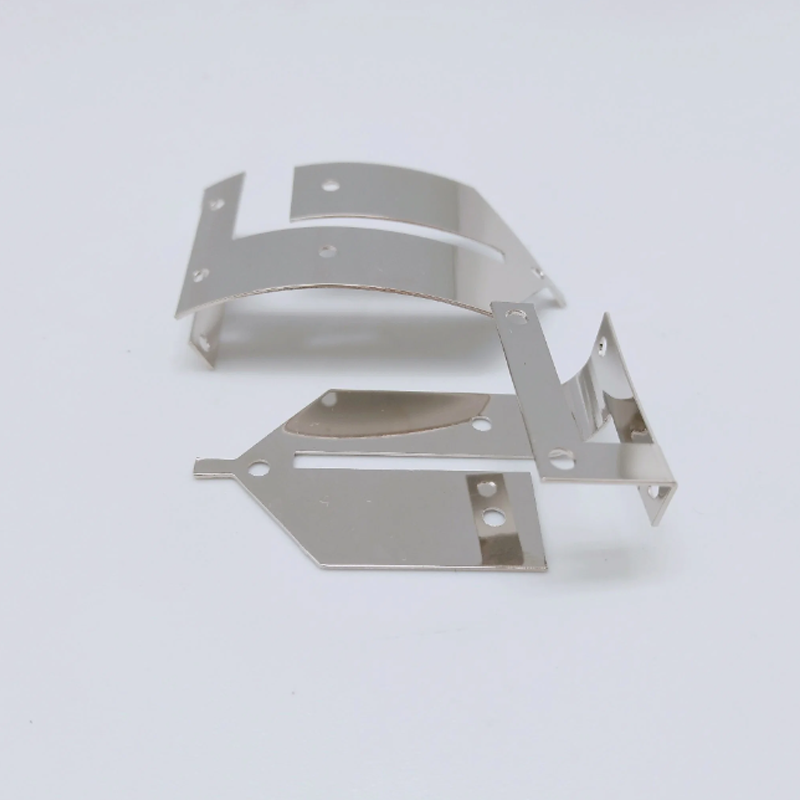

Steel Bracket Laser Cutting and Stamping for Sheet Metal Fabrication

Finding the right supplier for your custom sheet metal fabrication needs can be challenging. At Runze Metal, we’ve specialized in precision fabrication since 2003, ensuring your products are tailored to your exact specifications. With our commitment to swift communication, we guarantee a response to your inquiry within 1 hour, eliminating any communication hurdles. Moreover, our competitive pricing stems directly from our factory, offering you the best value for your investment. Rest assured, our rigorous quality control measures, spanning from raw materials to shipment, ensure impeccable product quality. Click now to request a quote and experience the Runze Metal difference.

Features:

| Detail | Item |

| Material Options | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper |

| Processing Options | Laser Cutting, Precision Stamping, Bending, CNC Punching, Threading, Riveting, Drilling, Welding |

| Surface Treatments | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen Printing, Sandblasting |

| Tolerance | +/-0.2mm, with comprehensive QC inspection before delivery, including a quality inspection report |

| Logo Application | Silk printing, Laser marking |

| Size Customization | Tailored to your specifications |

| Color Options | White, Black, Silver, Red, Grey, various Pantone and RAL colors |

| Accepted Drawing Formats | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft |

| Sample Lead Time | 1-3 workdays (no surface treatment), 3-5 workdays (with surface treatment) |

| Pricing Terms | EXW, FOB, CIF |

| Payment Terms | Samples: 100% payment upfront; Mass production: 50% deposit, balance before delivery |

| Certifications | ISO9001:2015, SGS, TUV, RoHS |

| Packing Options | Packaged in cartons or as per your request |

The Advantages of Our Company:

- Wide Material and Processing Options:

– Offering diverse materials like carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, and copper.

– Comprehensive processing capabilities including laser cutting, precision stamping, bending, CNC punching, threading, riveting, drilling, and welding.

- High-Quality Surface Treatments:

– Providing various surface treatments such as brushing, polishing, anodizing, powder coating, plating, silkscreen printing, and sandblasting for enhanced product durability and aesthetics.

- Precision and Quality Control:

– Maintaining a tight tolerance of +/-0.2mm with thorough QC inspections before delivery, including a quality inspection report to ensure top-notch product standards.

- Customizable Design Options:

– Tailored size customization, extensive color choices (including Pantone and RAL colors), and custom logo applications through silk printing and laser marking.

- Efficient Lead Times and Flexible Terms:

– Quick sample lead times (1-3 workdays for no surface treatment, 3-5 workdays with surface treatment) and competitive pricing terms (EXW, FOB, CIF).

– Convenient payment terms with 100% upfront for samples and 50% deposit for mass production, balance before delivery.

- Certified Quality Assurance:

– Accredited with ISO9001:2015, SGS, TUV, and RoHS certifications, ensuring compliance with international quality standards and regulations.

By choosing our company, you benefit from extensive material and processing options, high-quality surface treatments, precise quality control, customizable designs, efficient lead times, flexible terms, and certified quality assurance.

Reviews

There are no reviews yet.