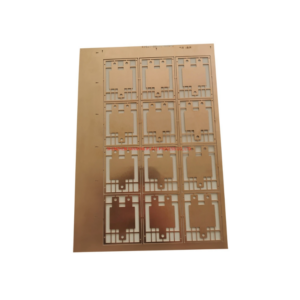

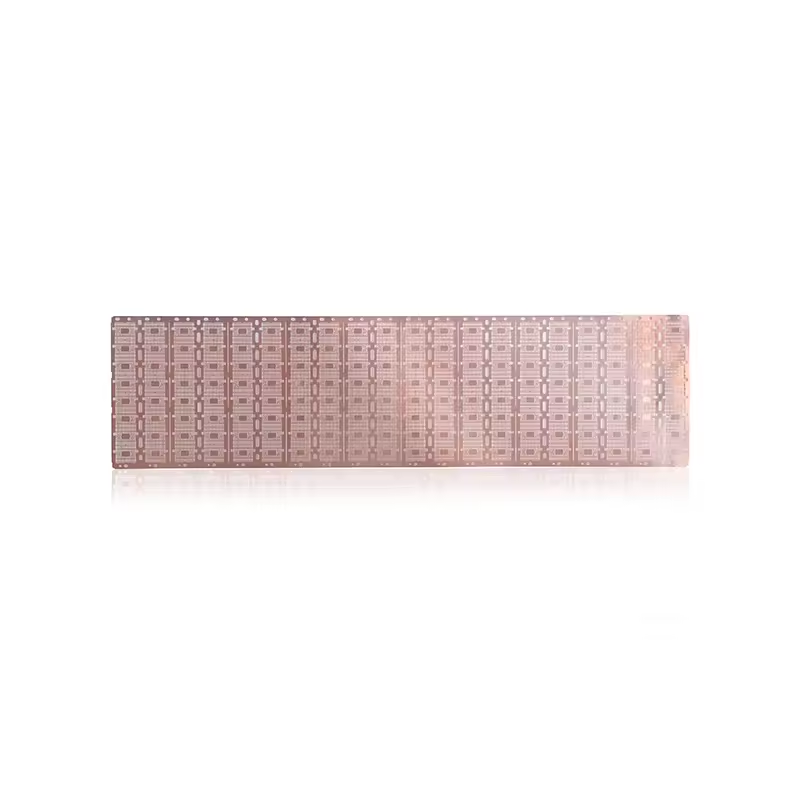

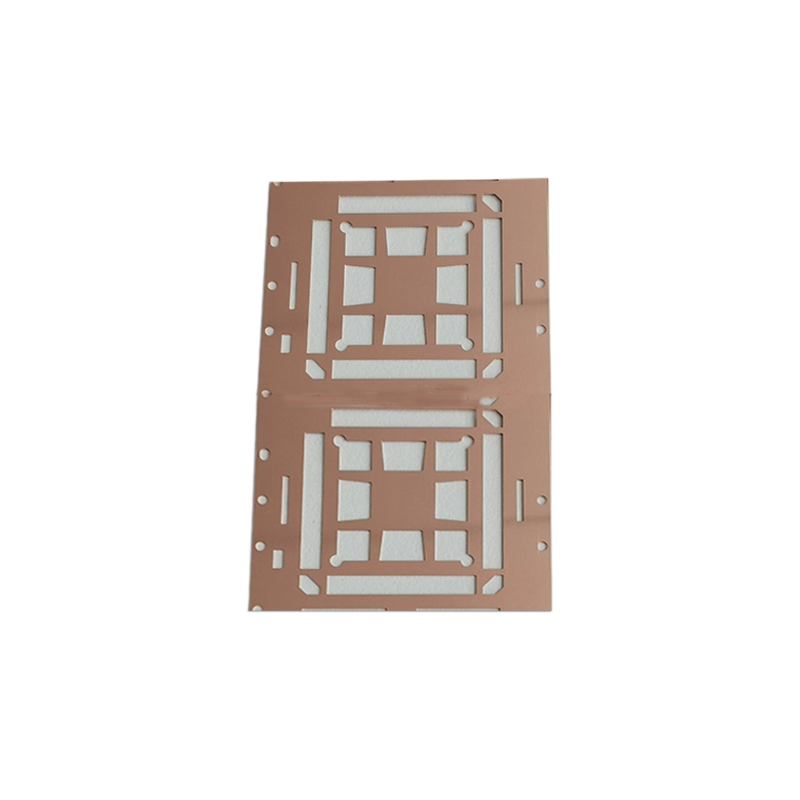

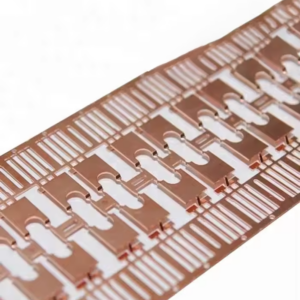

Custom Laser Cutting Metal Bracket Fabrication for Lead Frames

Lead frames, or semiconductor lead frames, are vital metal structures in chip packages that transmit signals from the die to the outside environment. These frames, typically thin metal layers, support semiconductors during packaging. High-density lead frames are produced through precise etching, ideal for complex designs requiring miniaturization, while low-density frames are manufactured via cost-effective stamping techniques. These methods ensure tailored solutions for various applications, enhancing the reliability and performance of semiconductor devices in industries ranging from consumer electronics to automotive systems.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand | OEM/ODM |

| Process | Stamping, Stamped, Laser Cutting |

| Material | Stainless Steel, Aluminum, Brass |

| Application | Used Widely |

| Certificate | ISO, RoHS, CE |

| Tolerance | 0.01-0.05mm |

| Size | Customized Size |

| Surface Treatment | Electroplating, Anodizing, Polishing, Brushing, etc. |

| Service | OEM/ODM Service |

| MOQ | According to your demand |

| LOGO | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen printing, Sandblast, etc |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. |

Other Features of Metal Lead Frames:

– Versatile Design Capabilities

– High Precision Manufacturing

– Minimal or No Mold Costs

– Burr-Free Production

– Quick Turnaround Times

Packaging and delivery:

– Customized Package:Tailored to your specifications.

– Port:Xiamen Port

– Selling Units:Single item

– Package Dimensions:13.99 x 12 x 12.5 cm

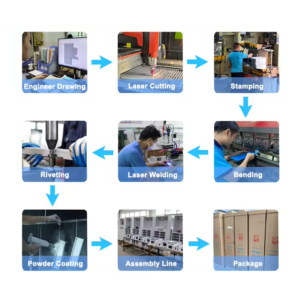

Sheet metal processing:

Our Advantages:

– Cost-Effective Tooling:Eliminates the need for expensive dies and molds.

– Versatile Material Thickness:Capable of fabricating metals as thin as 0.02 mm up to 1.2 mm.

– Precision Engineering:Maintains the design specifications without the need for alteration processes.

– Exceptional Accuracy:Ensures high precision in every production run.

– Diverse Designs:Supports various apertures, shapes, and bar combinations.

– Burr and Stress-Free:Utilizes manufacturing methods that avoid burrs and stress.

– Rapid Prototyping:Quick turnaround times to meet urgent prototype requirements.

– High Volume Production:Equipped to handle large-scale manufacturing efficiently.

-300x300.png)

Reviews

There are no reviews yet.