Durable Factory Manufacturing Yellow Insulated Ring Terminal Connector

Characteristics:

– Place of Origin: Xiamen, China

– Brand: OEM

– Type: Crimp Terminal

– Material: Copper Auto Electric Terminal

– Color: Red, Blue, Black, Yellow

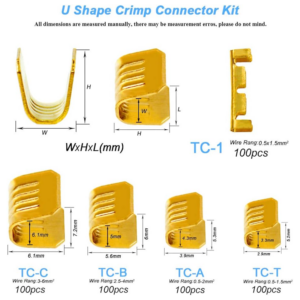

– Size:

– 0.5-1.5mm

– 1.5-2.5mm

– 2.5-4mm

– 4-6mm

– Insulation Material: PVC Auto Ring Electric Terminal

– Sample: Available

– Shape: Custom

Production Process:

- Design for Manufacturability (DFM) Report:

– Develop a comprehensive DFM report that evaluates the design’s feasibility and identifies potential manufacturing challenges. This includes assessing the product design for optimal moldability and cost-effectiveness

- Mold Design:

– Create detailed and precise mold designs using advanced CAD software. This step involves defining mold geometry, cavity layout, and essential features based on the product specifications and requirements.

- Material Selection:

– Choose high-quality materials for mold construction, such as steel alloys or specialized polymers, based on the requirements of the product and the intended application.

- CNC Machining:

– Utilize CNC (Computer Numerical Control) machines to precisely cut and shape mold components. CNC machining ensures high accuracy and consistency in mold parts production.

- Laser Cutting:

– Employ laser cutting technology for intricate and detailed cuts in mold components. This process provides high precision and clean edges, essential for complex mold designs.

- Wire Cutting:

– Use Wire EDM (Electrical Discharge Machining) to cut intricate details and complex shapes in the mold components. Wire cutting is critical for achieving high precision and fine tolerances.

- Grinding:

– Perform grinding to refine mold surfaces and ensure smooth finishes. This process enhances the accuracy of mold components and removes any residual machining marks.

- Mold Assembly:

– Assemble all mold components, including cavities, cores, and inserts, into a complete mold structure. This step involves fitting parts together with precision to ensure proper functionality.

- Stamping:

– Apply stamping processes to create specific features or impressions on the mold. Stamping is used for adding logos, text, or other surface details as required.

- Sample Inspection:

– Conduct thorough inspections of sample molds to verify that they meet design specifications and quality standards. This includes testing for functionality, accuracy, and overall performance.

- Mass Production:

– Once the sample mold is approved, initiate mass production. This phase involves producing molds in large quantities, ensuring consistency and quality across all units.

- Cleaning:

– Clean molds thoroughly to remove any residual debris or contaminants from the manufacturing process. Proper cleaning is essential to maintain mold quality and ensure optimal performance.

- Packing:

– Package the completed molds securely to prevent damage during transportation. Packaging includes protective materials and labeling to ensure safe and accurate delivery.

- Delivery:

– Coordinate the delivery of molds to the client’s location. This step involves logistics management to ensure timely and secure transportation of the molds.

- After-Sales Service:

– Provide comprehensive after-sales support, including maintenance, troubleshooting, and any necessary adjustments. This ensures that molds continue to perform well and meet client expectations over time.

Why Choose Us:

– Precision Injection Molding: Utilizing advanced injection molding techniques to ensure terminals are easy-entry types, facilitating seamless assembly.

– Automatic Plugging Compatibility: Designed to meet the demands of automatic plugging, ensuring compatibility with 100% copper wire crossings.

– Stringent Quality Control: Implementing a comprehensive series of quality control measures to maintain high standards throughout production.

– TP2 Copper Material: Constructed from TP2 copper material known for its exceptional conductivity and durability.

– High Production Output: Achieving significant output capacity, surpassing competitors with a production rate five times higher.

– Decades of Expertise: Drawing from decades of experience specializing in terminal production, with a dedicated focus on OEM service.

– Replacement for Quality Issues: Commitment to swift replacement in case of quality concerns, ensuring customer satisfaction.

– Customizable and Exquisite Packaging: Offering tailored and sophisticated packaging options, accommodating unique customer requirements.

Reviews

There are no reviews yet.