Certification

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback

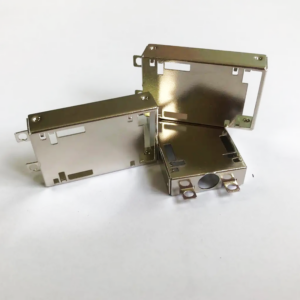

Surface Treatments for Metal Stamping Parts

- Electroplating

– Description: A process that deposits a layer of metal onto the surface of the part using an electric current. Commonly used for improving corrosion resistance and enhancing appearance.

– Types: Nickel plating, chrome plating, zinc plating.

- Powder Coating

– Description: A dry coating process where powdered paint is electrostatically applied and then cured under heat. It provides a durable, high-quality finish with excellent resistance to scratches, chipping, and fading.

- Anodizing

– Description: An electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant layer. Anodizing also enhances appearance and can be dyed in various colors.

- Plating

– Description: The application of a thin layer of metal to the surface of the part to improve wear resistance, reduce friction, or provide an aesthetic finish.

– Types: Tin plating, copper plating.

- Spraying

– Description: A method where paint or protective coating is sprayed onto the part’s surface. This process is used for both aesthetic and protective purposes, offering a wide range of colors and finishes.

- Oxidation

– Description: A chemical treatment that forms a protective oxide layer on the surface of metals, such as steel. It improves corrosion resistance and can provide a unique aesthetic finish.

- Polishing

– Description: A mechanical process that smooths and shines the surface of the part. Polishing removes imperfections and enhances the visual appeal of the metal.

- Sandblasting

– Description: A process that uses high-speed abrasive particles to clean or roughen the surface. It prepares the surface for further treatments or provides a textured finish.

- Passivation

– Description: A treatment process that enhances the natural oxide layer on stainless steel to improve corrosion resistance. It involves soaking the part in a solution that removes free iron and other contaminants.

Materials and Customization

Materials: Carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy

Customization: Sizes and dimensions can be tailored according to customer requirements

Applications: Network devices, communication equipment, computers, household appliances, distribution systems, educational toys, among others

Reviews

There are no reviews yet.