The Production Process for Our Metal Stamping Parts:

- Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

- Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

- Material Preparation

– Select and prepare metal sheets according to the required specifications.

- Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

- Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

- Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

- Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

- Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

- Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

- After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

Factory Show

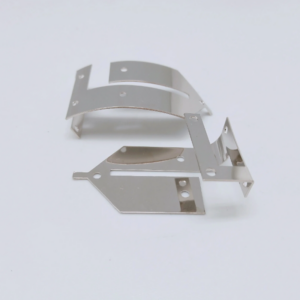

Advantages of Our Metal Stamping Parts

- Precision Engineering

– Our metal stamping parts are crafted with high precision, ensuring exact dimensions and consistent quality for optimal performance.

- High Durability

– Utilizing robust materials and advanced stamping techniques, our parts exhibit superior strength and durability, suitable for demanding applications.

- Rapid Production Turnaround

– Our state-of-the-art equipment and streamlined processes enable quick production cycles, meeting tight deadlines and high-volume demands.

Reviews

There are no reviews yet.