Overview:

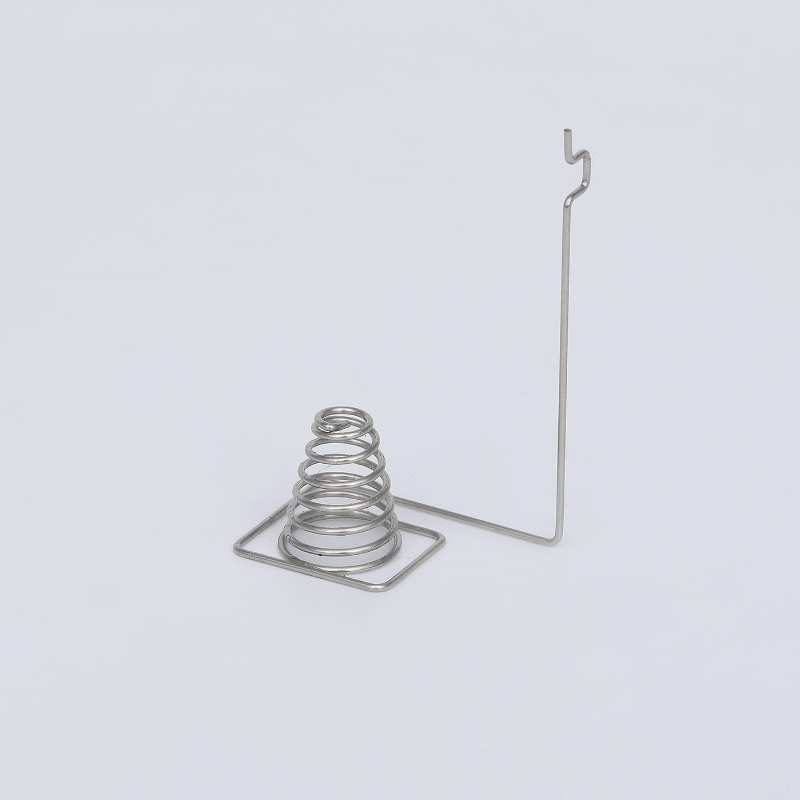

Wire forming reshapes wire materials using techniques like piercing, bending, and shearing, essential in industries such as automotive, food production, and medical equipment. This process handles various metals, including aluminum, brass, and steel. Starting with coiled wire, the material is straightened before further processing with manual or CNC machines. Common wire forms, like springs, clips, and hooks, are customized to meet specific needs. We provide custom wire forming solutions, ensuring top quality for your applications.

Details:

| Attribute | Details |

| Shape | Custom |

| Surface Treatment | Zinc/Nickel/Black Plating, Anodizing, etc. |

| Process | Laser Cutting, Bending, Stamping |

| Surface Finish | Polishing |

| Quality Control | 100% QC Test |

| Drawing Format | 2D/3D/CAD/Dwg/Step/Pdf/Igs |

| Feature | OEM Support |

| Thickness | 0.05mm ~ 16.0mm / Customization |

| Service | OEM Customized |

| Color | Custom |

| Transport Package | Bubble Bag + Carton + Wooden Box |

| Specification | Customized |

| Trademark | Customized |

| Origin | Xiamen, China |

The Advantages of Wire Forming:

Wire forming plays a crucial role in various industries, providing essential components for a wide range of applications:

– Electrical Appliances: Electricians often use wire forms, such as tin-plated copper clips, to securely fasten electrical wiring and support certain electrical equipment.

– Hooks: Wire-formed hooks serve as reliable connectors in many parts and assemblies, offering strength and durability.

– Light Fixtures: In lighting systems, wire forming is used to create wires that support and secure fixtures within ceilings or walls.

– Custom Wire Springs: The versatility of wire forming allows for the production of custom wire springs tailored to specific applications and unique requirements.

– Additional Uses: Wire forming also finds its place in industries like safety equipment, telecommunications, and textile machinery, proving its adaptability across various sectors.

Surface Treatments for Wire Forming:

- Zinc Plating: Offers excellent corrosion resistance and is commonly used in applications where durability and protection from rust are essential.

- Nickel Plating: Provides a smooth, polished finish with enhanced wear resistance and a high level of corrosion protection, ideal for aesthetic and functional purposes.

- Powder Coating: Delivers a durable, high-quality finish that improves resistance to impact, moisture, and chemicals, making it perfect for both indoor and outdoor use.

- Electropolishing: A process that smooths and passivates the surface, providing superior corrosion resistance and a clean, bright finish, often used in medical and food-grade applications.

These treatments help improve the longevity and performance of wire-formed components in various environments.

Why Choose Us?

Industrial Experience

We have been specializing in the spring industry since 1998, bringing years of expertise and knowledge to our field.

Sample Availability

We can provide samples for your approval within 7 days. Samples are free of charge if we have the tool readily available.

Fast Delivery

Our standard delivery time is typically within 10 days.

Exceptional Service and Quality

Our business philosophy is centered on offering the best competitive pricing, excellent service, and superior quality.

Reviews

There are no reviews yet.