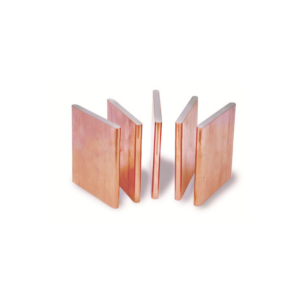

Bus bars serve as a critical junction between input and output power, efficiently collecting input currents and distributing them to output circuits. Constructed from stamped conductive materials, typically copper, bus bars are designed to minimize maintenance, labor, and installation costs. Their quick and easy connection and installation make bus bars a versatile solution across various applications. Our bus bars are produced using advanced stamping techniques, ensuring high-quality performance and reliability. We also offer a wide range of customization options to meet your specific needs, including tailored designs, materials, and configurations.

Basic Information

Processing: Stamping

Materials: Steel, Stainless Steel, Brass, Copper, Bronze, Aluminum, Titanium, Silicon Steel, Nickel Plate, etc.

Additional Processing: Machining, Laser Cutting, CNC Bending, Plastic Injection, Welding, Riveting, Die/Mould Development, etc.

Tolerance: 0.01mm

Surface Treatment :Brushing, Polishing, Electrophoresis, Anodizing, Powder Coating, Plating, Silk Screen, Laser Engraving, etc.

Quality System Certificate: ISO 9001

Lead Time :Depends on customer’s drawing and request

QC System: Full inspection before shipment for every processing

Packaging: 1) Standard Package

2) Pallet or Container

3) As per Customized Specifications

Payment Terms T/T, L/C, PayPal

Custom Process:

Supply Requirements Assessment:

– Evaluate and determine specific product requirements as per customer specifications and preferences.

– Collaborate with customers to gather detailed information and ensure alignment with desired outcomes.

Sample Validation:

– Conduct thorough validation of product samples to verify compliance with customer expectations and quality standards.

– Ensure that samples meet all specified criteria before proceeding with mass production.

Production and Quality Assurance:

– Execute comprehensive production processes while adhering to established quality standards and protocols.

– Implement rigorous quality inspection procedures at every stage of production to maintain product integrity and consistency.

Packaging and Logistics:

– Strategically package finished products according to customer preferences and shipping requirements.

– Organize efficient shipping and logistics processes to ensure timely and secure delivery to customers’ specified locations.

Why choose us?

1) We have our own factory, quality can be controlled seriously and price is very competitive.

2) We have been manufacturing metal stamping parts for nearly 30 years..

3) We have professional testing equipment and quality control personnel.

4) We have own R&D department experienced technicians.

5) On timely delivery and 24/7 service.

Reviews

There are no reviews yet.