Battery terminal connectors play a critical role in ensuring a secure and efficient connection between a battery and an electrical system. These connectors form the essential link that allows the battery to deliver power to various devices and equipment.

In this post, we will provide a comprehensive overview of the various types of battery terminal connectors available on the market, along with key considerations for selecting the right connector to meet your specific requirements. Additionally, we will guide you through the process of properly connecting battery terminals, giving you a clear understanding of the necessary steps.

What are battery terminal connectors?

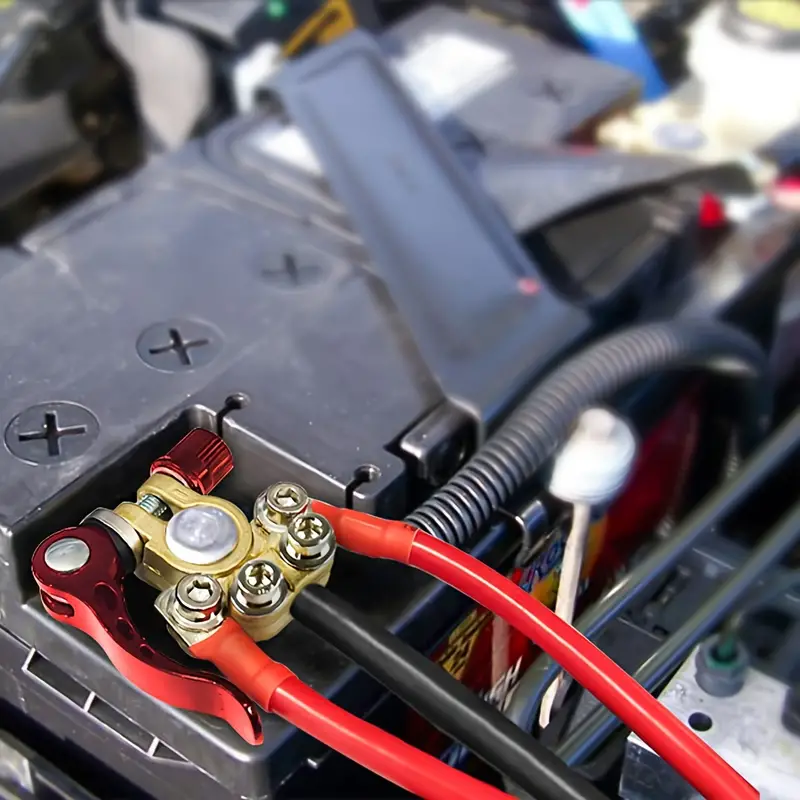

Battery terminal connectors are critical components for establishing secure and reliable electrical connections between batteries and various devices or systems. Manufacturers typically construct these connectors from highly conductive materials such as copper or brass, which optimize the flow of electricity. By ensuring smooth power transmission from the battery to the connected device—whether it’s a vehicle, a flashlight, or a remote-controlled toy—these connectors play a pivotal role in maintaining uninterrupted electrical performance. Available in various shapes and sizes, all battery terminal connectors are designed with the same objective: to facilitate efficient power transfer. Without properly functioning terminal connectors, batteries would be unable to consistently power the devices we rely on.

Battery terminal connector types

-

Post Terminal Connectors

Post terminal connectors, also known as stud terminal connectors, are among the most widely used types of battery connectors. These connectors feature a threaded stud that securely fastens to the battery terminal. They are frequently utilized in automotive, marine, and industrial applications due to their reliability and durability.

-

Lug Terminal Connectors

Lug connectors, often referred to as spade or U-shaped terminals, are typically crafted from copper or aluminum. These connectors are available in a range of sizes to suit different applications and wire gauges. Lug terminals are commonly employed in heavy-duty scenarios such as electric vehicles, renewable energy systems, and large industrial machinery due to their robustness and ability to handle high current loads.

-

Clamp Terminal Connectors

Clamp connectors, also known as alligator clips, are easily recognizable by their spring-loaded jaws that allow them to quickly attach to battery terminals. Widely used in automotive applications, battery chargers, and testing devices, these connectors are ideal for creating temporary connections, making them perfect for diagnostic and testing procedures.

-

Ring Terminal Connectors

Ring terminal connectors are distinguished by their circular, ring-shaped design, which allows for secure attachment to battery posts or studs. These connectors are a popular choice in automotive, marine, and electrical systems where a stable, long-lasting connection is necessary. Ring terminals come in various sizes and materials, designed to accommodate different wire gauges and specific application needs.

-

Flag Terminal Connectors

Flag connectors, sometimes referred to as blade terminals, are flat, rectangular-shaped connectors featuring holes for wire attachment. These connectors are commonly used in automotive applications, such as wiring for fuse boxes, switches, and relays. Flag terminal connectors are valued for their ease of installation and removal, as well as the secure electrical connections they provide.

-

Splice Terminal Connectors

Splice terminal connectors are designed to join or splice multiple wires together. They are widely used in electrical installations, automotive wiring systems, and DIY projects. Splice connectors are available in several varieties, such as crimp-on, heat-shrink, and twist-on types, each offering different levels of reliability, insulation, and ease of use depending on the application.

Expert Tips for Selecting the Right Battery Terminal Connectors

When selecting battery terminal connectors, it is crucial to take the following factors into account:

Application: Identify the specific application and the associated electrical requirements for your project. Different applications may necessitate various types of connectors to guarantee compatibility and optimal performance.

Material: Opt for connectors constructed from high-quality materials such as copper or brass, known for their excellent conductivity and durability. Steer clear of connectors made from inferior materials that may be prone to corrosion or degradation over time.

Wire Size: Consider the wire gauge or size that will be paired with the connector. Ensure that the terminal connector is compatible with the wire size to establish a reliable and secure connection.

Environmental Conditions: Evaluate the environmental factors in which the connectors will be utilized. Conditions such as temperature fluctuations, moisture levels, and exposure to chemicals or vibrations can significantly impact the performance and longevity of the connectors. Select connectors specifically designed to withstand these environmental challenges.

Ease of Installation: Choose connectors that facilitate straightforward installation and provide a secure connection. Some connectors may require specialized tools or techniques for proper installation, so consider the available resources and expertise.

Safety Compliance: Confirm that the chosen connectors adhere to relevant safety standards and regulations. Look for connectors equipped with features such as insulation, strain relief, and protection against short circuits or accidental disconnections to enhance safety.

How are battery terminals connected?

Here’s a concise guide to connecting battery terminals: Preparation: Before beginning, ensure that the battery and electrical system are powered off or disconnected to prevent accidents or short circuits. Select the Appropriate Connector: Choose the correct type of terminal connector based on the battery terminal style and the specific application. Common connector types include top post connectors, side post connectors, ring terminals, and clamp connectors. Clean the Terminals: Thoroughly clean the battery terminals and connectors using a wire brush or terminal cleaner to eliminate any corrosion or dirt buildup. Position the Connector: Carefully align the connector over the battery terminal, ensuring correct polarity (positive or negative). Secure the Connector: Utilize the appropriate hardware, such as bolts or screws, to firmly secure the connector in place. Ensure the hardware is tightened adequately to maintain a stable connection. Verify the Connection: After securing the connector, gently tug it to confirm it is firmly attached to the battery terminal. Check for any loose connections or signs of instability. Test the Connection: Once the terminals are connected, test the battery to ensure it functions properly. This can involve starting a vehicle, powering a device, or using a multimeter to measure voltage levels.

Conclusion

In summary, battery terminal connectors are essential components that ensure secure and efficient connections between batteries and electrical systems. Understanding the different types of connectors, including post terminal connectors, lug terminals, clamp connectors, and others, is crucial for selecting the right solution for your specific application. Key factors to consider when choosing connectors include the application requirements, material quality, wire size compatibility, environmental conditions, ease of installation, and safety compliance.

If you have any questions or need assistance regarding battery terminal connectors or any related issues, please feel free to contact us. Our team is dedicated to providing prompt and knowledgeable support to address your inquiries. Your satisfaction and safety are our top priorities.