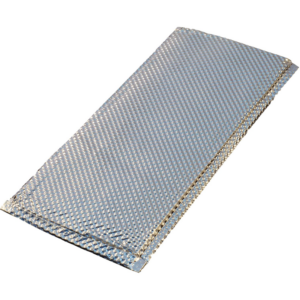

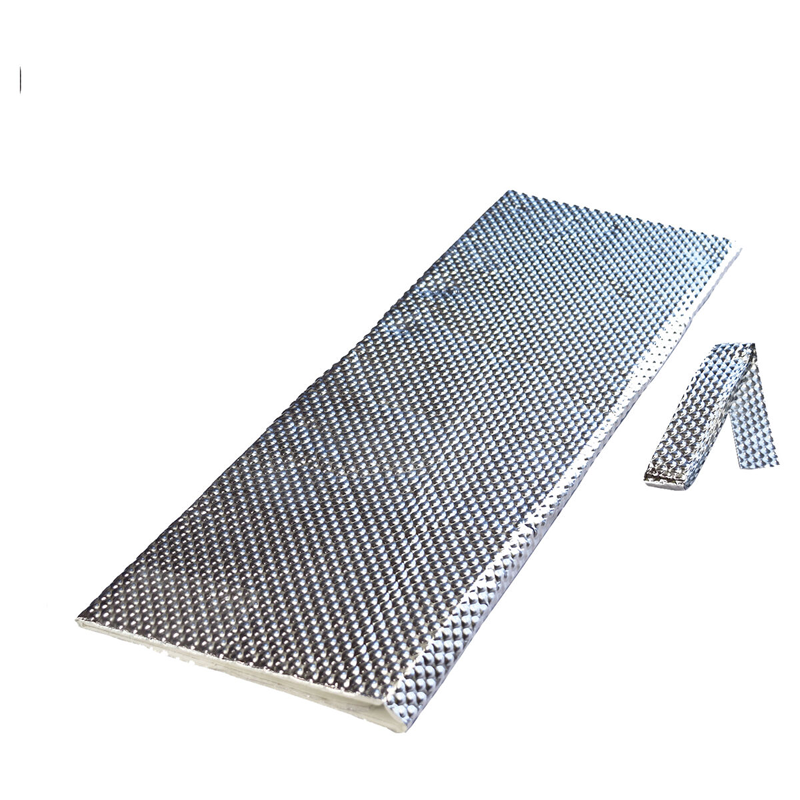

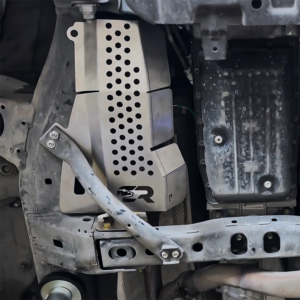

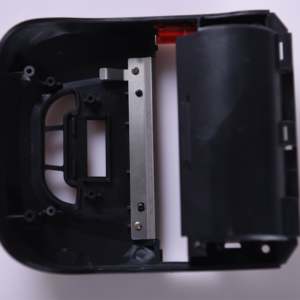

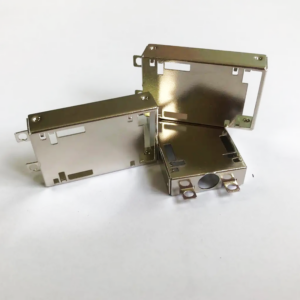

Our custom heat shields are engineered to provide superior thermal protection across a variety of industries and applications. Manufactured using advanced processes such as precision cutting, stamping, and forming, these shields are designed to withstand extreme temperatures and offer optimal heat insulation. Whether used in automotive engines, industrial equipment, or electronic devices, our heat shields ensure durability and high performance. Customization options include material selection, size, shape, and finish, allowing us to tailor each heat shield to your exact specifications. Contact us today to discuss your heat shield requirements and get a competitive quote.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Advantages of Our Product

Lighter weight

Lower cost

Higher load-carrying capacities

More resistant to shock loads and oscillations

More tolerant of shaft misalignments

Why Choose Us?

Advanced Technology

We leverage state-of-the-art four-slide and multi-slide stamping press technology to produce high volumes of metal parts with exceptional precision and efficiency. This method is particularly effective for cost-efficient manufacturing of small, high-precision components like bushings. Our process is further enhanced by the use of CAD/CAM software, EDM techniques, and cutting-edge CNC machinery, ensuring that every product adheres to exact customer specifications.

In-House Tooling and Die Making

Our comprehensive in-house tooling and die-making capabilities enable rapid modifications to designs without additional wait times or costs. This control over the tooling process allows us to deliver high-quality parts with shorter turnaround times.

ISO-Certified Facilities

We operate three fully equipped facilities, each certified to ISO 9001, ISO 14001, and TS 16949 standards, ensuring top-tier quality and environmental management.

Cost-Effective Production

Our efficient metal forming techniques, including four-slide stamping, enable us to manage high-volume orders while maintaining low production costs.

Just-in-Time Delivery

Our advanced MRP system aligns with customer production schedules to provide timely deliveries. We offer custom labeling and digitally updated stock levels to ensure that products are delivered as close to the required time as possible.

Reviews

There are no reviews yet.