When manufacturing complex parts that require both high efficiency and precision, deep drawn stamping is often the process of choice. This manufacturing method is highly valued for its ability to produce parts in high volumes, combining speed, accuracy, and repeatability in a single, seamless process. By forming components in a single piece, deep drawn stamping not only eliminates the need for additional assembly but also ensures structural integrity and durability, as the process involves significant compression of the material. The resulting components are particularly durable and resistant to wear and tear due to the mechanical forces applied during production.

Deep drawn metal stamping is particularly advantageous in industries requiring lightweight, high-strength, and conductive properties in metal parts. The method is widely used for producing a diverse range of components across sectors such as automotive, electronics, and aerospace. While the strength and other properties of metal materials make them ideal for these applications, some parts may require additional treatments to meet specific requirements or improve performance. This is where heat treating comes into play, providing crucial enhancements to the properties of deep drawn components.

What Is Heat Treating?

Heat treating is a collection of processes that involve heating and cooling metal parts to modify their mechanical and physical properties while maintaining their structural integrity. By altering the internal structure of the material, heat treating enhances the material’s characteristics such as strength, hardness, and ductility, making it more suitable for specific applications. This process is critical when working with metals, especially for parts subjected to high-stress environments or those requiring precise tolerances. There are several heat treating processes used in conjunction with deep drawn stamping, each offering different advantages depending on the material and intended application.

Common Heat Treating Processes

-

Annealing

Annealing is one of the most widely used heat treatment methods for deep drawn components. This process involves heating the metal to a designated temperature and then cooling it slowly, which helps to reduce hardness and increase ductility, making the material easier to work with. The annealing process alters the crystalline structure of the metal, improving its formability while reducing residual stresses that may have been introduced during the deep drawing process.

-

Hardening

Hardening involves heating the metal to a high temperature and then rapidly cooling it in a liquid (usually water or oil). This method increases the hardness and strength of the material by creating a more stable and uniform grain structure. It is particularly useful for components that will be subjected to wear and tear or extreme environmental conditions.

-

Quenching and Tempering

Quenching is a rapid cooling process that enhances the hardness of metals. It is often followed by tempering, which involves reheating the quenched metal to a lower temperature to relieve stresses and adjust hardness levels for improved toughness. This combination is commonly used for materials such as steel, which require a balance between hardness and strength.

-

Case Hardening

Case hardening is a heat treatment process designed to harden the outer surface of a part while maintaining a softer, more ductile interior. This method is particularly useful for components that need high surface hardness but must retain a strong internal structure to prevent cracking or failure.

The Role of Annealing in Deep Drawn Components

Among the heat treating processes, annealing is especially critical for deep drawn components. The deep drawing process applies significant stress to the material, which can lead to strain hardening and increased brittleness. Annealing helps to reduce this strain and restore the material’s ductility, allowing it to be further formed or processed without failure. This process is typically applied between forming stages to relieve stress and improve the metal’s overall properties. In particular, stainless steel alloys, such as AM350, are commonly annealed to improve formability without compromising corrosion resistance or overall strength.

Annealing is also essential when working with materials like aluminum, brass, and copper, which are often used in deep drawn components for their lightweight and conductive properties. By applying heat treatment, manufacturers can ensure these materials maintain the desired mechanical properties, making them suitable for applications in electronics, automotive, and other demanding industries.

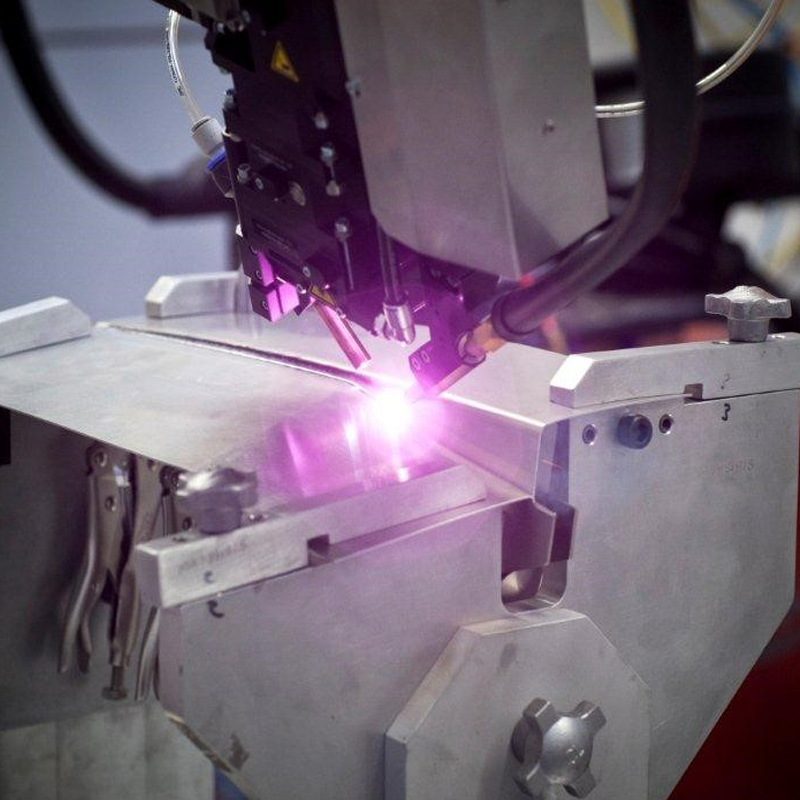

Equipment Used for Heat Treating Deep Drawn Components

To achieve precise and consistent results, heat treating deep drawn components requires advanced equipment. At Topmetalstamping, we leverage state-of-the-art machinery and technologies to ensure high-quality heat treatment processes. Our equipment includes:

– Vacuum Annealing Furnaces

These furnaces are designed to provide precise control over the heating and cooling process, allowing for optimal annealing conditions in a controlled vacuum environment. This type of equipment is ideal for heat treating alloy materials, stainless steel, and other metals sensitive to oxidation.

– Humpback (Belt) Annealing Systems

Our humpback annealing systems offer precise control over the heating atmosphere, particularly in applications where hydrogen or other gases are required. The unique “humpback” design allows for efficient processing of materials, reducing contamination and ensuring uniform heating.

– Retort Heat Treat Furnaces

These sealed vessels are used for heat treating metals in inert atmospheres such as argon or nitrogen. The controlled environment prevents oxidation, ensuring that delicate components retain their mechanical properties throughout the process.

– High-Temperature Heat Treatment Ovens

These ovens are used for processes that require high-temperature heat treating, such as quenching and tempering, ensuring precise control over the temperature to achieve the desired material properties.

Why Choose Topmetalstamping for Your Deep Drawn Components?

At Topmetalstamping, we pride ourselves on our expertise in deep drawn stamping and heat treating, ensuring that every component we produce meets the highest industry standards. We offer a wide range of custom metal parts for various applications, all manufactured with the utmost attention to detail and quality. Our team consists of experienced engineers and technicians who are skilled in both the deep drawn stamping process and the latest heat treating methods, ensuring that your components are made to last.

Our commitment to excellence is backed by our advanced equipment and years of experience in the field. With a focus on precision and efficiency, we can produce high-quality, cost-effective deep drawn components with tailored heat treatment processes to meet your specific requirements. Whether you’re in the automotive, electronics, or aerospace industry, we have the capability to produce components that perform reliably under the most demanding conditions.

We also understand that different applications have unique requirements. Whether you need components with specific mechanical properties, dimensional tolerances, or surface finishes, we are equipped to handle a wide range of customization options. Our ability to integrate heat treating into the deep drawn stamping process ensures that your parts will meet both functional and aesthetic requirements without compromise.

Contact Topmetalstamping Today

If you’re in need of high-quality deep drawn stamped components that require precise heat treatment, look no further than Topmetalstamping. We have the resources, experience, and advanced equipment necessary to produce parts that meet your exact specifications and deliver superior performance. Reach out to us today to learn more about our deep drawn stamping and heat treating capabilities or to discuss your project requirements. We look forward to partnering with you to provide reliable, cost-effective solutions for your manufacturing needs.