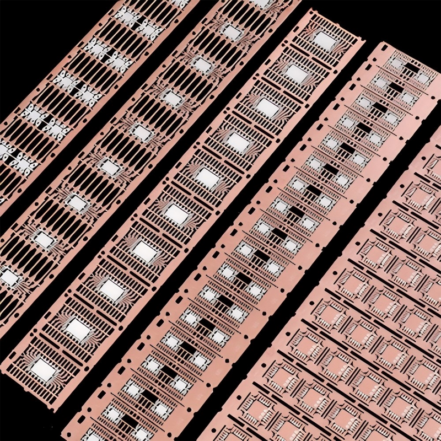

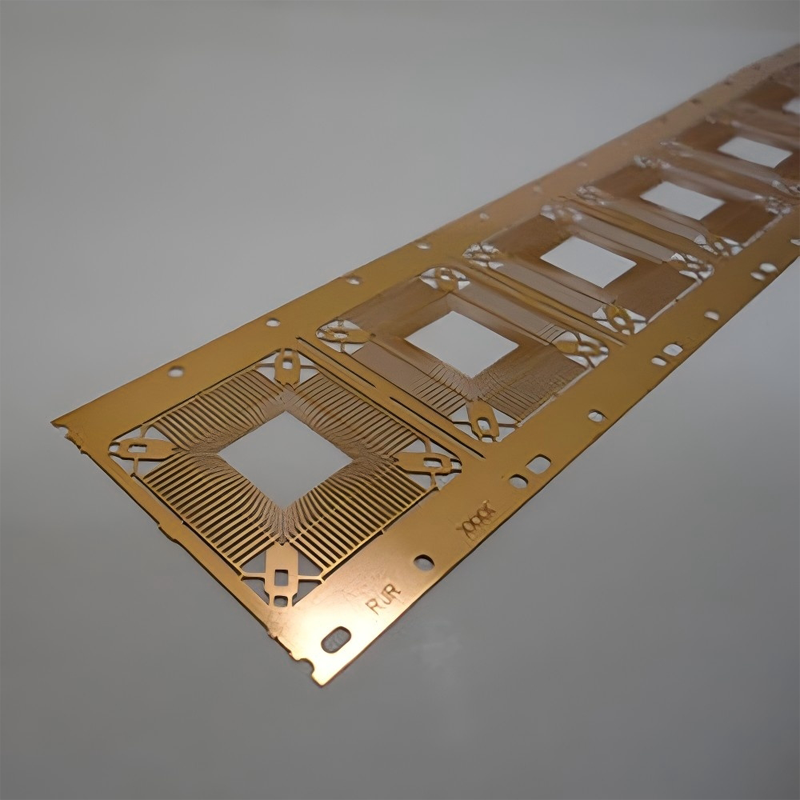

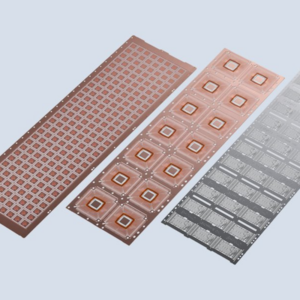

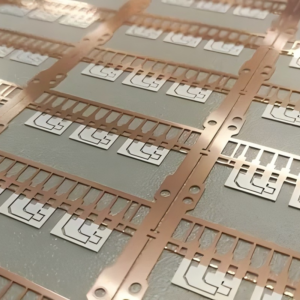

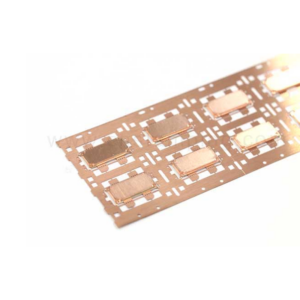

IC lead frame is a crucial component in the semiconductor industry, used to connect integrated circuits (ICs) to external circuits. Made from high-quality materials like copper or copper alloys, IC lead frames provide mechanical support and electrical conductivity for ICs, ensuring reliable performance in various electronic applications. These lead frames are precisely manufactured using stamping or molding processes to create intricate patterns that fit the IC’s package and facilitate smooth electrical connections. IC lead frames are widely used in consumer electronics, automotive systems, medical devices, and telecommunications equipment. With their durability, high conductivity, and resistance to heat and corrosion, they are designed to meet the rigorous demands of modern electronics.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

The Production Process for Our Metal Stamping Parts:

-

Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

-

Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

-

Material Preparation

– Select and prepare metal sheets according to the required specifications.

-

Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

-

Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

-

Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

-

Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

-

Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

-

Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

-

After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

Reviews

There are no reviews yet.