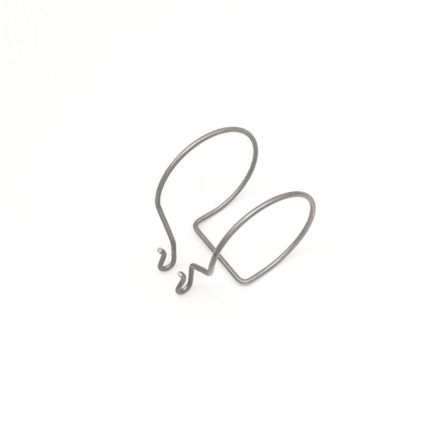

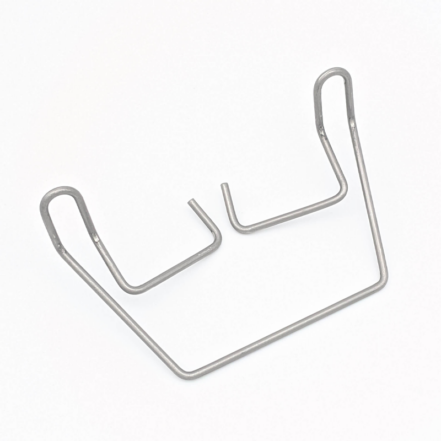

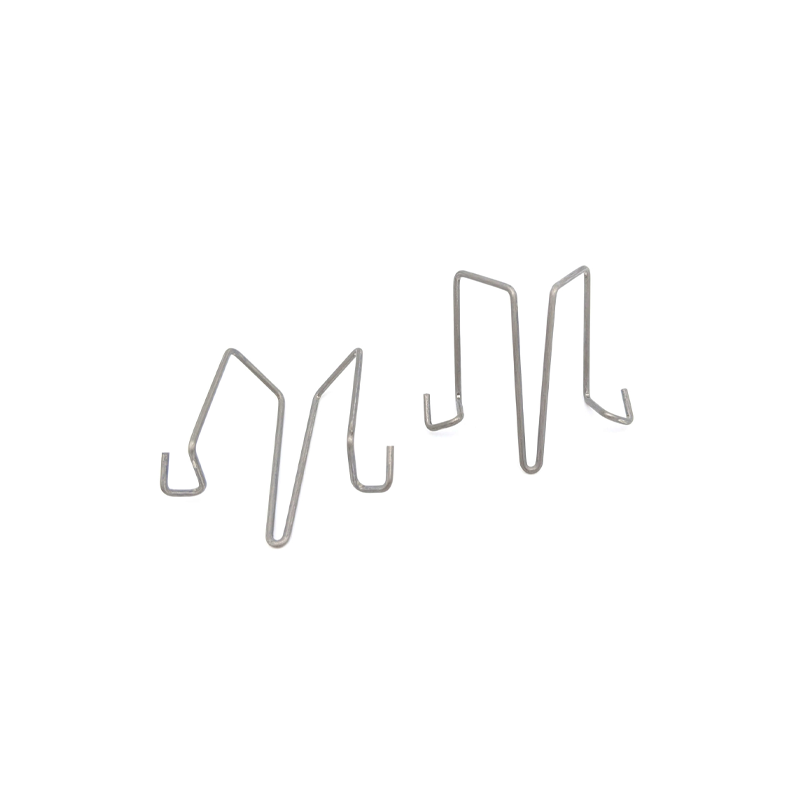

Solar Spring and Wire Forms are precision-engineered components commonly used in solar panel assemblies and various other industrial applications. Made from high-quality metals such as stainless steel, copper, or spring steel, these components are designed to provide reliable mechanical support, electrical conductivity, and flexibility. In solar panels, solar springs and wire forms are often used for grounding, mounting, and ensuring secure connections between cells and other electrical components. Their durable construction ensures resistance to harsh environmental conditions, including temperature fluctuations and exposure to the elements. These custom-formed wire components are crafted using advanced manufacturing techniques, such as cold forming and wire bending, to meet specific design requirements. Solar springs and wire forms play a vital role in enhancing the performance and longevity of solar energy systems by ensuring stability and reducing wear over time.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Advantages of Our Product

-

Precision Engineering

– Our metal stamping parts are crafted with high precision, ensuring exact dimensions and consistent quality for optimal performance.

-

High Durability

– Utilizing robust materials and advanced stamping techniques, our parts exhibit superior strength and durability, suitable for demanding applications.

-

Cost-Effective Production

– The efficiency of our stamping processes minimizes material waste and reduces production costs, offering economical solutions for large-scale manufacturing.

-

Rapid Production Turnaround

– Our state-of-the-art equipment and streamlined processes enable quick production cycles, meeting tight deadlines and high-volume demands.

-

Versatile Applications

– Our metal stamping parts are versatile and can be customized to fit a wide range of industries including automotive, aerospace, and industrial applications.

-

Consistent Quality

– Rigorous quality control measures ensure that every part meets stringent specifications and industry standards, delivering reliable and consistent products.

-

Advanced Technology

– We employ cutting-edge technology, such as CNC machines and laser cutting, to achieve precise cuts and intricate designs with high efficiency.

-

Customizable Solutions

– We offer flexible customization options to meet specific design requirements and functional needs, providing tailored solutions for diverse projects.

-

Surface Treatment Options

– A variety of surface treatments, including plating and oxidation, are available to enhance the aesthetic appeal and performance of our metal stamping parts.

-

Sustainable Practices

– Our processes emphasize sustainability by reducing waste and optimizing material usage, aligning with environmentally responsible manufacturing practices.

Reviews

There are no reviews yet.