Overview:

Our factory has earned a reputation as a leading manufacturer of high-quality stamped metal components, trusted by prominent companies across industries such as automotive, appliances, and more. We specialize in the design, production, and assembly of custom metal clips, offering a wide range of shapes and sizes to meet diverse application needs. In addition to our stamping capabilities, we provide secondary services such as vacuum hardening, oil quenching, and austempering, complemented by extensive plating options to ensure durability and performance. Partner with us to explore a variety of material, shape, and size choices tailored to your specific requirements.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Surface Finish | Stainless Finish, Powder Coating, Polishing, etc. |

| Quality Certification | ISO 9001 |

| Manufacturing Process | Metal Stamping, Bending, Welding |

| Tolerance | ±0.01mm |

| Lead Time | Sample: 3-5 Days; Production: 10-20 Days |

| Quality Control | 100% Inspection Before Shipping |

Production Process:

-

Design and Prototyping

The process begins with the design of the custom clip, where CAD drawings are created based on the specific application requirements. Prototypes are then developed to test and validate the design.

-

Material Selection

High-quality materials such as stainless steel, carbon steel, aluminum, brass, or copper are chosen based on the clip’s intended use, durability, and environmental conditions.

-

Metal Stamping

The selected material is fed into a stamping press, where it is formed into the desired shape through precision die cutting. This process ensures consistent dimensions and shapes.

-

Secondary Operations

Additional operations such as bending, welding, or forming are performed to refine the clip, giving it the necessary strength and shape for its specific function.

-

Surface Treatment

Depending on the requirements, the clips are subjected to various surface treatments, including powder coating, polishing, or electroplating to enhance corrosion resistance and appearance.

-

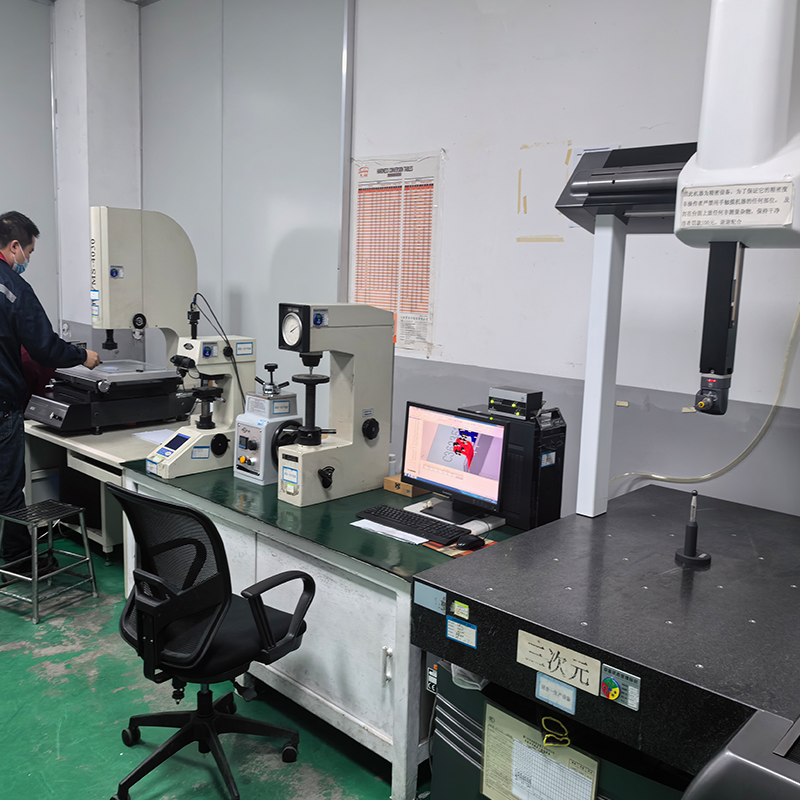

Quality Control

Each clip undergoes a thorough inspection process, including dimensional checks, functionality testing, and visual inspections to ensure it meets quality standards.

-

Packaging and Shipping

Once the clips pass quality control, they are carefully packaged and prepared for shipment, ensuring they arrive in perfect condition for use in the final application.

Common Materials for Clips and Fasteners

Industrial clips and fasteners are manufactured from a variety of materials, selected based on application requirements and budget considerations. The most commonly used materials include:

– High Carbon Steel

– Low Carbon Steel

– Stainless Steel

– Cold Rolled Steel

– Brass

– Beryllium Copper

– Phosphor Bronze

– Aluminum

– Nickel

Factory Show:

Reviews

There are no reviews yet.