Overview:

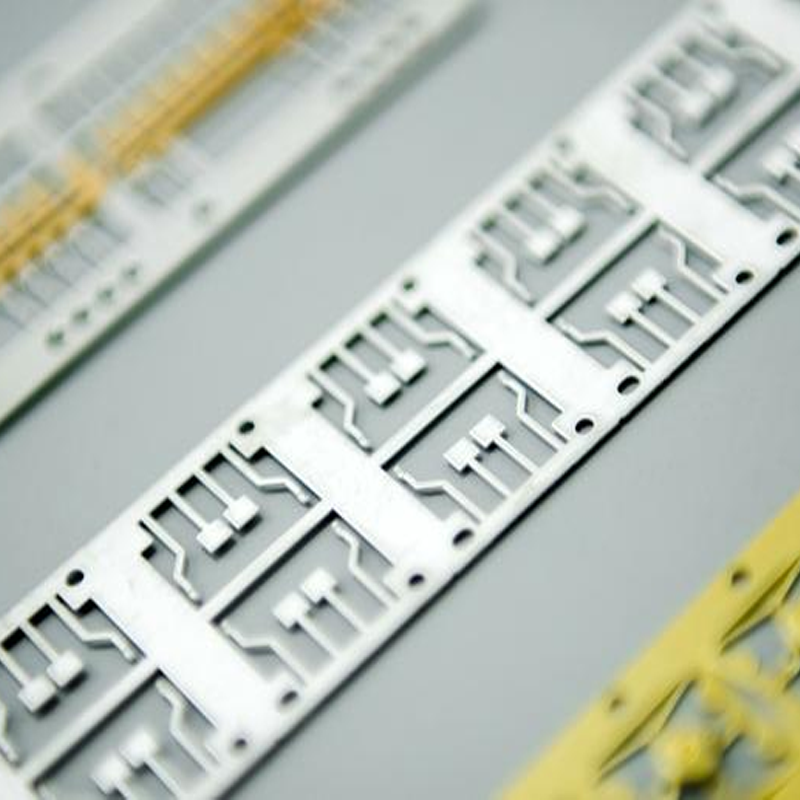

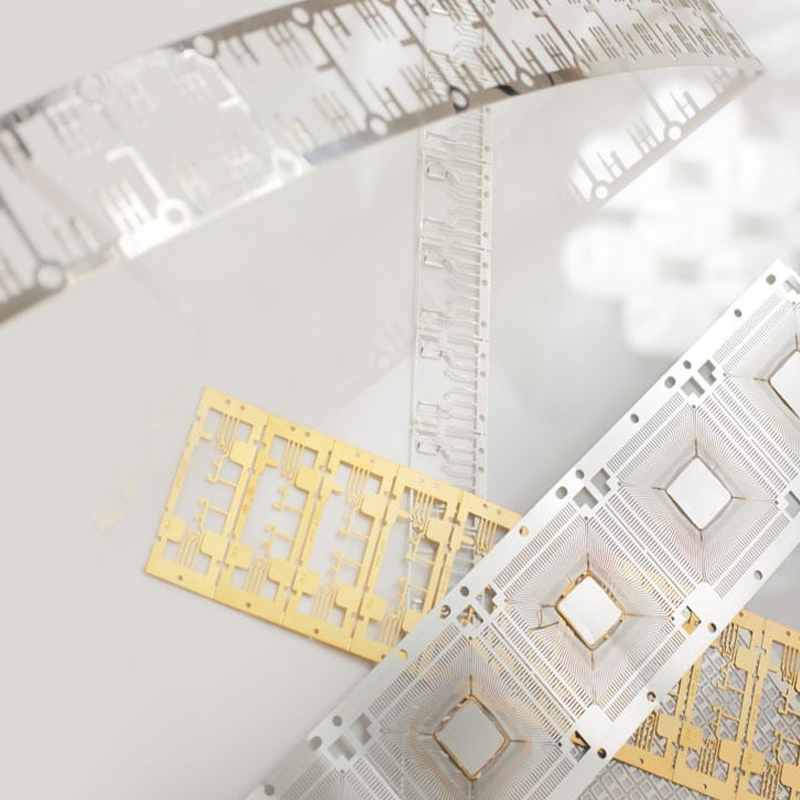

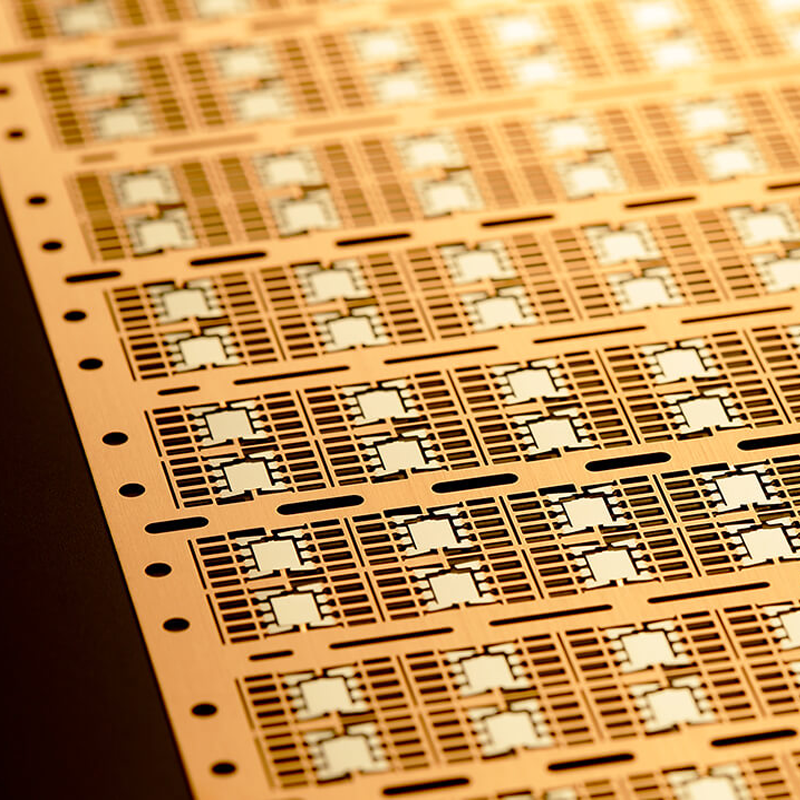

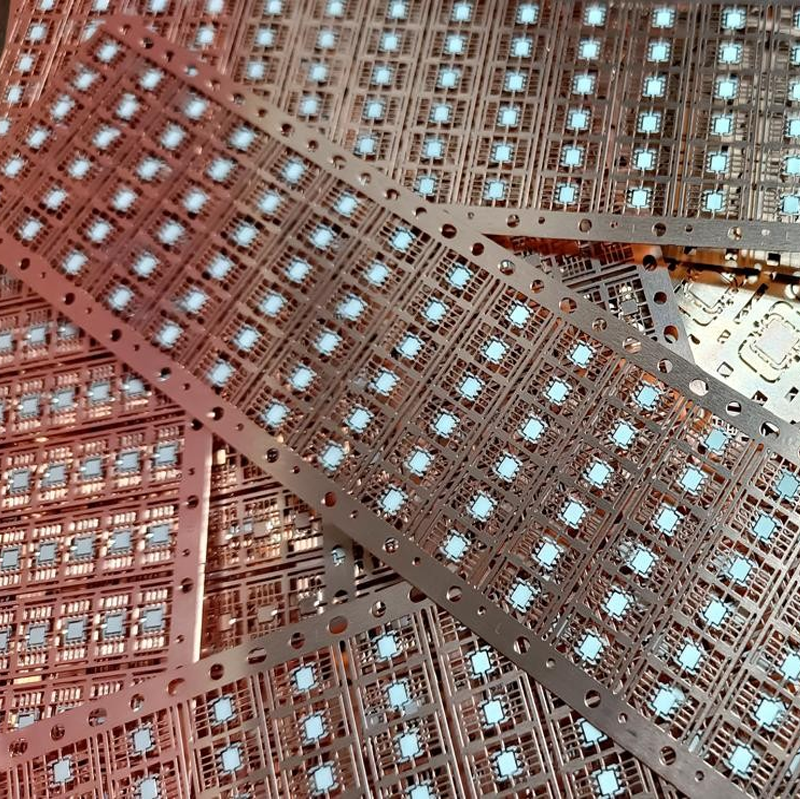

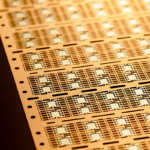

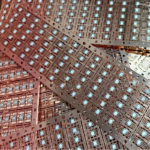

A lead frame is a crucial component in semiconductor packaging, serving as a thin metal plate that connects the semiconductor’s tiny electrical terminals to larger-scale circuitry. Also known as a leadframe, it plays a vital role in ensuring the efficient operation of automotive, electronics, and electrical devices. Due to their precision, even the smallest defect in lead frames can compromise semiconductor adhesion and the overall functionality of the device. At Topmetalstamping, we specialize in manufacturing high-quality, high-precision lead frames for various industries, including automotive, electronics, and electrical applications. Trust us to provide reliable, durable lead frames that meet the strict demands of your semiconductor assembly processes.

Details:

| Attribute | Details |

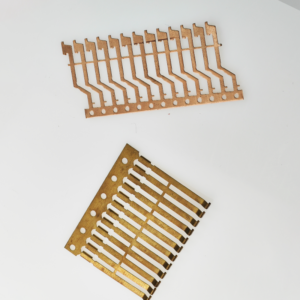

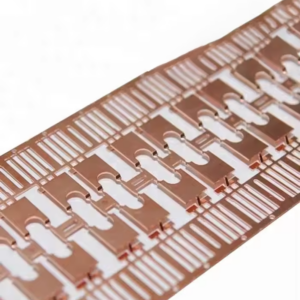

| Type | Cold Stamping |

| Processing Type | Shaping Metal |

| Material | Stainless Steel |

| Mold | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | General Stamping |

| Tolerances | 0.02mm |

| Customized | Warmly Welcomed |

| Trademark | OEM |

| Transport Package | Carton |

| Origin | Xiamen, China |

Surface treatment options:

-

Electroplating

This involves coating the lead frame with a thin layer of metal (such as gold, silver, or nickel) using an electrochemical process. Electroplating improves corrosion resistance, conductivity, and the overall aesthetic of the lead frame.

-

Nickel Plating

Often used for its excellent corrosion resistance, nickel plating is a common surface treatment for lead frames. It provides a hard, durable surface that enhances solderability and prevents oxidation.

-

Gold Plating

Gold plating is typically used for applications requiring superior conductivity and corrosion resistance, particularly in high-end electronics and semiconductor packaging. This treatment ensures long-lasting performance in high-reliability environments.

-

Tinning

Tinning involves applying a thin layer of tin over the lead frame to improve its solderability and prevent oxidation. It is widely used in the electronics industry for efficient and reliable connections.

-

Passivation

Passivation is a chemical process that removes free iron from the surface of stainless steel lead frames, creating a protective oxide layer. This treatment enhances the lead frame’s corrosion resistance, especially in harsh environments.

-

Phosphating

Phosphating is a conversion coating process that provides excellent corrosion resistance and lubrication properties. It is often used to improve the overall longevity of lead frames, particularly in automotive and industrial applications.

-

Anodizing

Although more commonly associated with aluminum, anodizing can be applied to certain metals to create a protective oxide layer that increases surface hardness, corrosion resistance, and aesthetic appeal.

-

Blackening

Blackening (or black oxide coating) is applied to steel lead frames to provide a corrosion-resistant, aesthetically pleasing black finish. It is used to improve durability without compromising electrical conductivity.

Customization Advantages

- Extensive Material Expertise

- Precision Engineering Capabilities

- Efficient Process Planning

- Skilled Production Team

- Advanced Manufacturing Equipment

- ISO 9001:2015 Certified Quality Management

Our Factory:

-300x300.png)

Reviews

There are no reviews yet.