Overview:

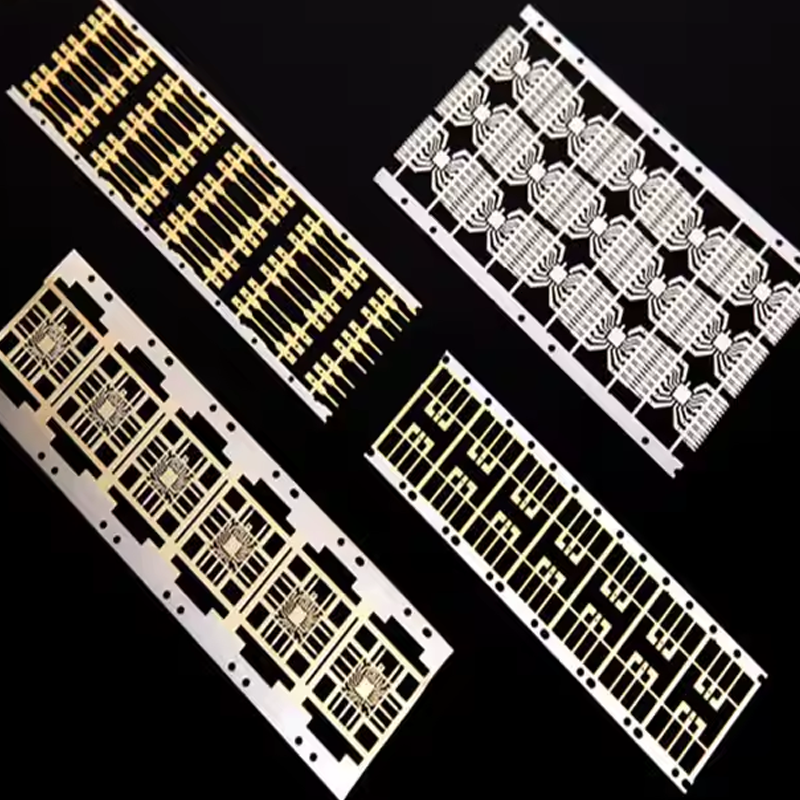

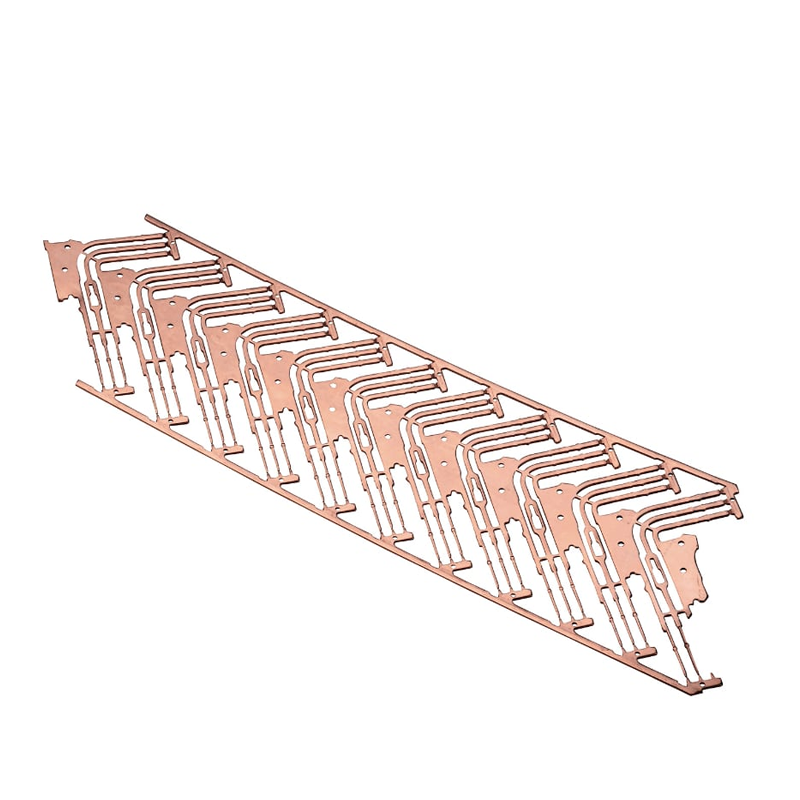

Our state-of-the-art facility employs advanced Four-slide, multi-slide, and punch press machinery to fabricate precision copper lead frames tailored to your specifications. Our experienced design team works closely with you to ensure all requirements are met. Our factory is proud to be ISO 9001, ISO 14001, and IATF 16949 certified, reflecting our commitment to maintaining the highest industry standards.

To guarantee exceptional quality, we capture data at every stage of the production process and conduct thorough final inspections before delivery. Contact us today to discover why our factory is the ideal partner for your custom copper lead frame needs.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Application | Telecommunication |

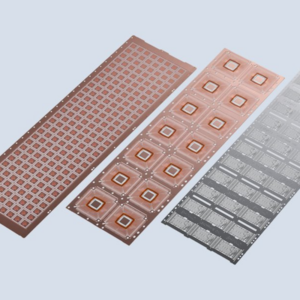

| Material | Copper |

| Technique | Metal Stamping |

| Mass Production Lead Time | 10 days |

| Plating | Zinc Plating |

| Package | Factory Package or Customized Package |

| Certificates | ROHS, ISO |

Surface Treatments:

– Polishing: High-precision surface polishing for a smooth, reflective finish.

– Plating Options: Zinc, Nickel, Silver, or Tin plating for enhanced corrosion resistance and durability.

– Powder Coating: Durable, protective powder coating for superior surface protection.

– Black Oxidation: Black oxidation treatment for increased wear resistance and an attractive matte finish.

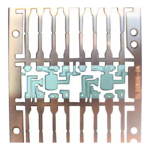

Production process:

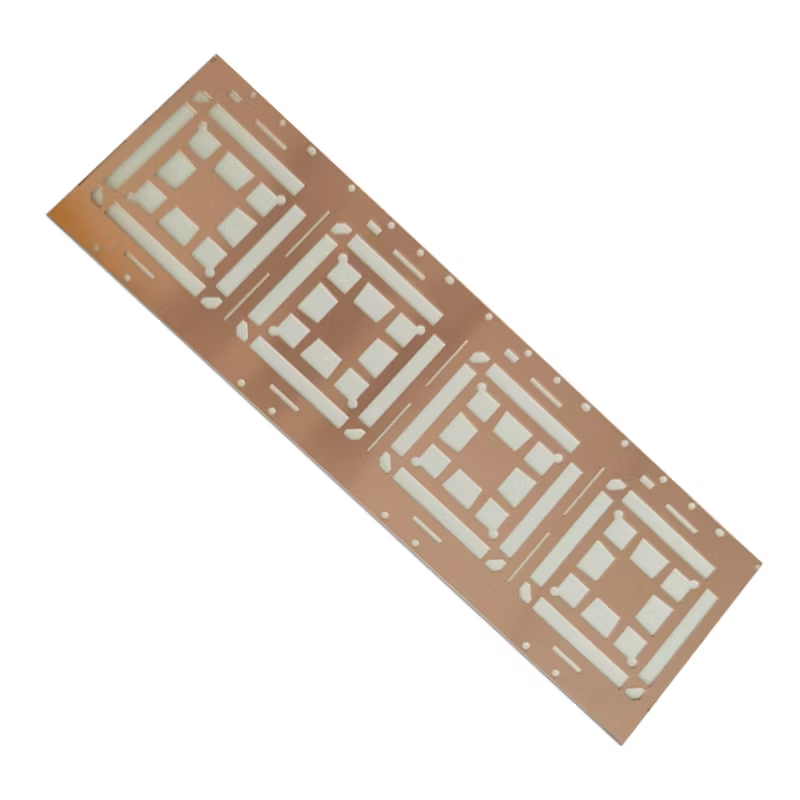

- Material Selection: High-quality copper is chosen based on its electrical conductivity and suitability for lead frame applications.

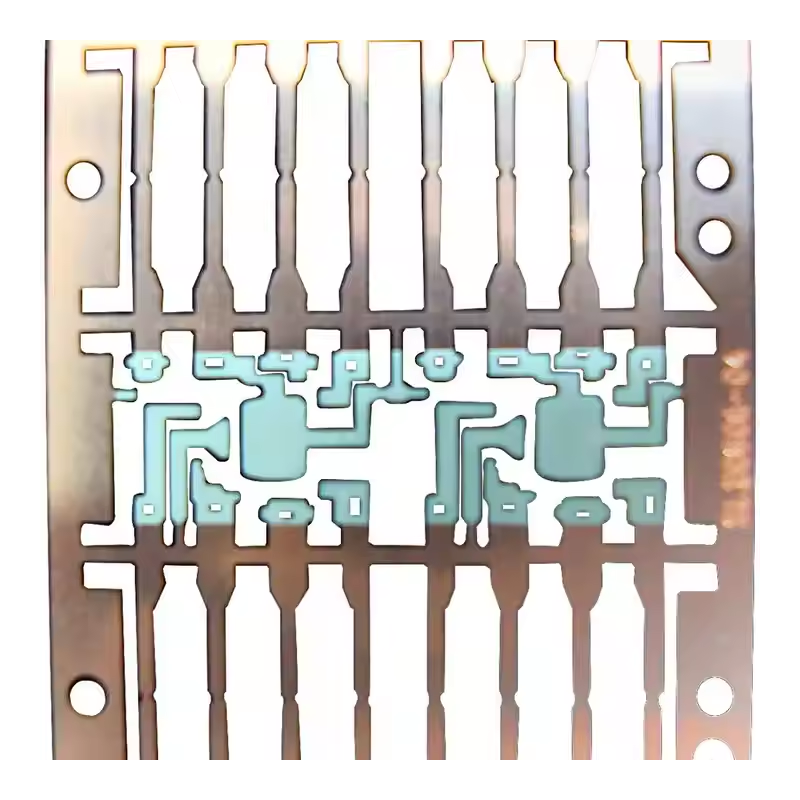

- Progressive Stamping: This crucial step involves the use of progressive dies to gradually form the copper lead frame through multiple stages. It ensures precision and consistency in shaping the lead frame, allowing for complex geometries and fine details.

- Cutting and Forming: After progressive stamping, the lead frame undergoes cutting and forming to achieve the desired dimensions and shape.

- Surface Treatment: The lead frame is treated with appropriate finishes such as plating (e.g., Zinc, Nickel, or Tin) or powder coating to improve durability, corrosion resistance, and aesthetic quality.

- Inspection and Quality Control: Throughout the manufacturing process, strict quality control measures are applied, including visual inspection and measurements, to ensure the lead frames meet the specified standards.

- Packaging: Finally, the completed copper lead frames are carefully packaged to prevent damage during transport, and prepared for delivery to customers.

Quality Assurance:

At our facility, quality is our top priority. We begin each project with a thorough feasibility review and a run-at-rate study to ensure quality before mass production. Our quality management system includes advanced technologies, continuous improvement initiatives, and a dedicated team, ensuring all parts meet stringent standards.

We utilize in-line and off-line vision systems, along with sensor technologies, to inspect part features and dimensions during production. This guarantees 100% quality with zero defects.

Understanding the need for custom solutions, we offer tailored designs to enhance lead frame performance. With extensive experience, Topmetalstamping is your trusted partner for precision lead frame manufacturing.

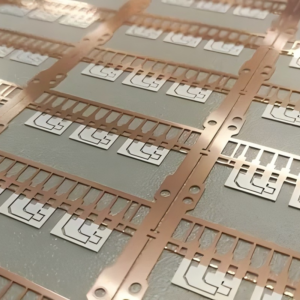

Factory Show:

Welcome to our cutting-edge facility, spanning 4,500 square meters and equipped with advanced machinery from leading international manufacturers. We leverage Germany CNC Mini Bending Machines for precise, high-quality bending operations, and Japan-made BOBBY equipment for high-precision tasks. Our Vickers Hardness Testers ensure rigorous material quality control, while Precision Grinders deliver exceptional surface finishes.

Our CNC equipment offers unmatched accuracy for complex parts, and High Pressure Punches enable efficient stamping. Additionally, Taiwan Liye machinery ensures reliable performance across various manufacturing processes. To uphold the highest quality standards, our Projectors meticulously verify component dimensions and tolerances.

This comprehensive, high-tech setup allows us to provide custom solutions, meeting both large-scale production demands and intricate, specialized designs with unparalleled precision and efficiency.

Reviews

There are no reviews yet.