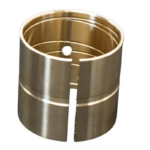

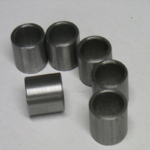

Description:

Metal stamping bushings are durable components widely used in automotive applications like suspension systems and engine mounts to reduce friction, absorb vibration, and ensure alignment. Made from materials such as stainless steel, brass, and aluminum, they are crafted through advanced processes like deep drawing for superior wear and corrosion resistance. Our ISO-certified facility offers custom manufacturing with a 150-ton monthly capacity, delivering precision, quality, and cost-effective solutions tailored to your needs.

Characteristics:

| Category | Details |

| Production Type | Mass Production |

| Machining Method | CNC Machining |

| Materials | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Titanium Alloy |

| Function | Assembly of Various Automation Equipment |

| Certificates | RoHS, GS, ISO9001, SGS |

| Inspection | Full Size Checked |

| Surface Finishing | Brushing, Galvanized, Laser Engraving, Silk Printing |

| Processing | CNC Turning, CNC Milling, CNC Machining, Grinding |

| Tolerance | ±0.005 mm |

| Surface Roughness | Ra 0.8-3.2 |

| Color | According to Customer’s Requests |

| Applications | Automotive, Communication Equipment, Electronic Appliances |

| Sample Service | Available |

| Size | According to Customer’s Drawings |

| Other Services | Assembly, Die Casting |

| Service | One-stop Service |

| Lead Time | 3-8 Days for Samples, Approx. 15 Days for Mass Orders |

| Transport Package | Safety Export Packaging |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 1,000,000 pieces/year |

Surface Treatment:

- Anodizing: A process that uses an electrolytic solution to create a durable, corrosion-resistant oxide layer on metal surfaces, typically aluminum. This treatment enhances the material’s resistance to wear and improves its aesthetic appearance, providing a matte or glossy finish depending on the specifications.

- Zinc Plating: This treatment involves coating the metal surface with a thin layer of zinc to protect against corrosion. It is commonly used for steel and iron parts to enhance their durability, prevent rusting, and extend their lifespan in harsh environments.

- Nickel Plating: A process that deposits a layer of nickel onto metal surfaces, offering excellent corrosion resistance, wear protection, and an attractive finish. Nickel-plated components are often used in automotive, industrial, and electronic applications for enhanced performance and aesthetic appeal.

- Powder Coating: A dry finishing process where a powdered paint is applied electrostatically and then cured under heat. Powder coating provides a durable, high-quality finish that is resistant to scratching, fading, and wearing, making it ideal for automotive, appliance, and architectural metal parts.

Quality Assurance:

Our quality assurance process for metal stamping bushings involves rigorous checks and inspections at every stage of production: technicians conduct self-checks during the manufacturing process, engineers perform spot checks throughout production, and our quality control team conducts thorough inspections on finished products before shipment. We utilize advanced inspection instruments, including height gauges, CMMs (Coordinate Measuring Machines), universal tensile testing machines, salt spray test chambers, dynamic balance detectors, pneumatic detection systems, universal hardness testers, calipers, electronic scales, micrometers, gage blocks, and pin gauges, to ensure the highest levels of precision, durability, and performance in our stamped components.

Factory Overview:

Reviews

There are no reviews yet.