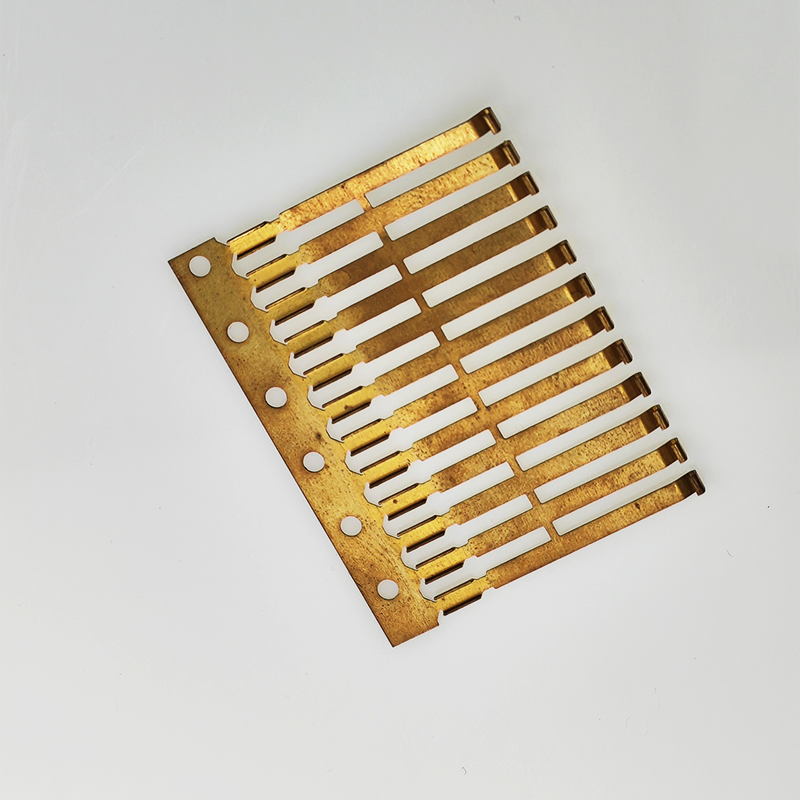

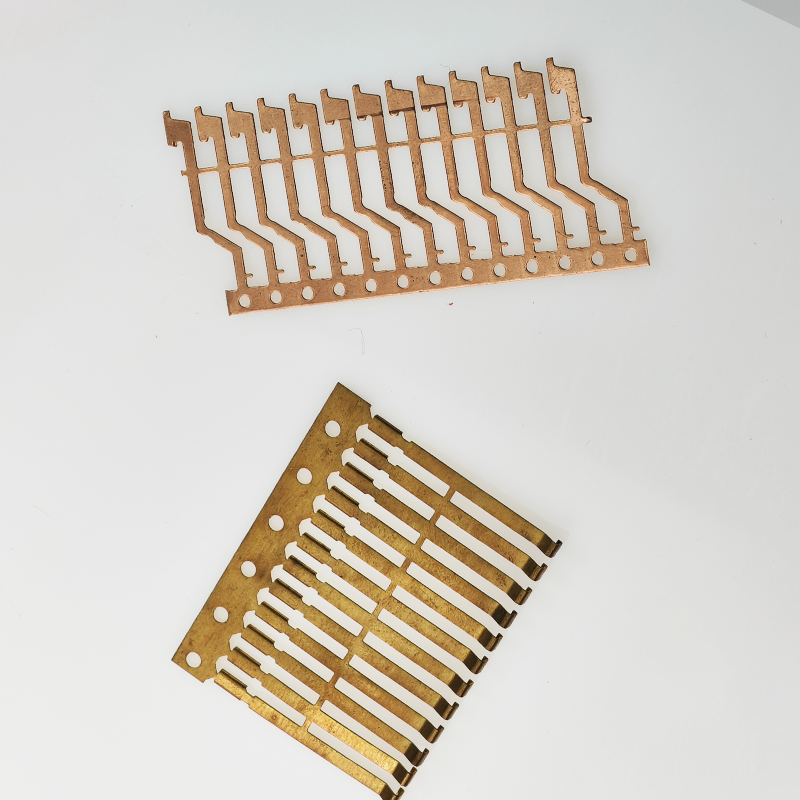

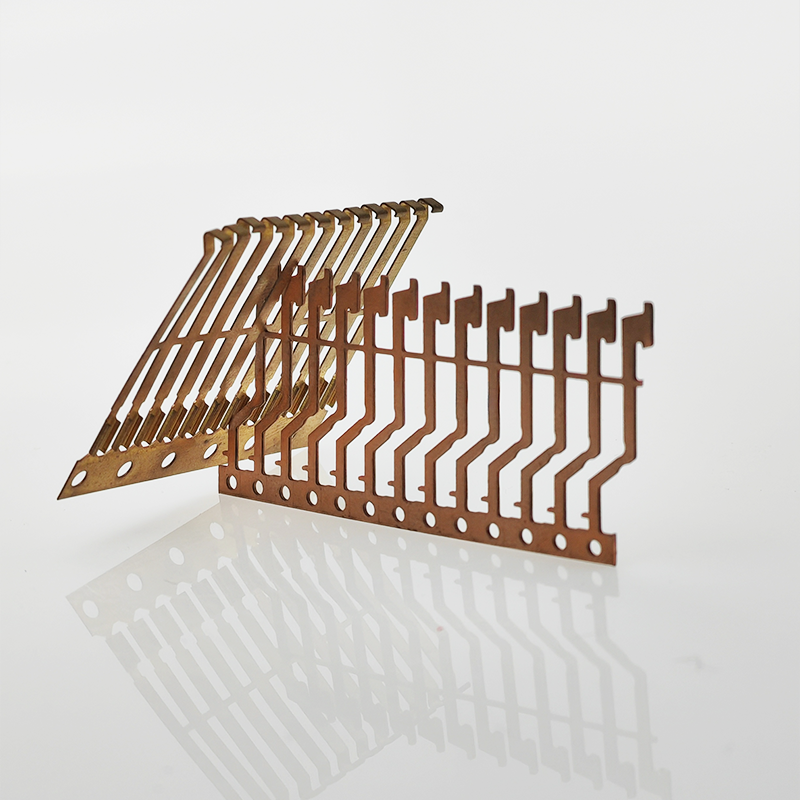

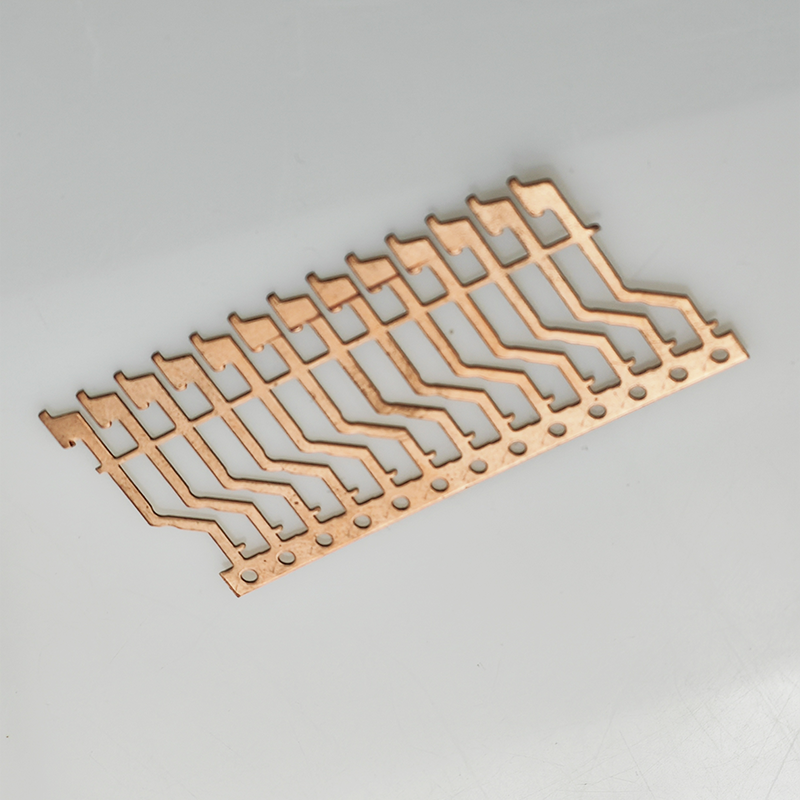

Description:

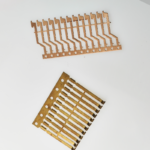

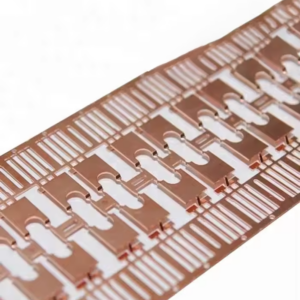

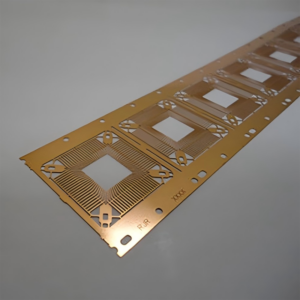

Our facility is equipped with advanced four-slide, multi-slide, and punch press technologies to produce custom lead frames designed to meet your precise specifications. Our skilled design team collaborates closely with you throughout the process to guarantee all requirements are fulfilled with the highest level of accuracy. As an ISO 9001, ISO 14001, and IATF 16949 certified manufacturer, we adhere to the most stringent industry standards.

To ensure exceptional quality, we employ comprehensive data tracking at each production stage and conduct a meticulous final inspection before shipment.Contact us today to discover why our facility is the optimal partner for your custom lead frame needs.

Details:

– Place of Origin: Xiamen, China

– Brand Name: OEM

– Material: Stainless Steel, Carbon Steel

– Design Software: UG, PROE, CAD

– Certificate: ISO 9001:2015

– Tolerance: +/− 0.002mm – +/− 0.05mm

– Process: Stamping, Punching

– Finish: Galvanized, Powder Coating, Painting

– Color: Custom

– MOQ: Small Order Can Be Accepted

– Packaging: Custom

Quality Control Process:

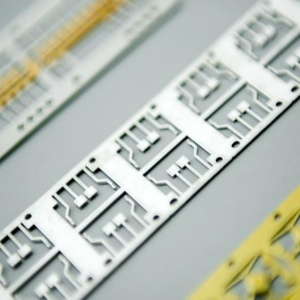

At Topmetalstamping, we prioritize quality at every step of the manufacturing process. Our approach begins with a comprehensive feasibility analysis to ensure that the design is fully manufacturable. We then conduct a run-at-rate study during the initial production phase to validate quality before proceeding to full-scale production, enabling our team to monitor processes closely for optimal performance.

To maintain rigorous quality standards, we implement cutting-edge in-line and off-line camera vision systems, coupled with advanced sensor technology, to inspect every part throughout the production cycle. This ensures that each component meets our strict criteria for zero defects and 100% quality assurance.

Our ISO-certified quality management system, coupled with ongoing improvement initiatives, ensures that every part produced adheres to the highest industry standards.

Understanding the need for precision in lead frame design, we provide customized solutions to meet the unique demands of critical applications. With extensive expertise in producing high-performance lead frames, our factory is your trusted partner for superior quality and precision in lead frame manufacturing.

Reviews

There are no reviews yet.