When working with electronics, whether in automotive, industrial, or consumer devices, selecting the correct electrical terminal can make a significant difference in the reliability and performance of your system. As small as these components might be, electrical terminals are vital for ensuring secure and efficient connections within any electrical circuit. They play a crucial role in transmitting electrical signals and power while keeping the wiring system organized and intact.

In this blog, we’ll take an in-depth look at the various types of electrical terminals, their specific uses, and what factors to consider when choosing the right terminal for your project. From material choices to the application environment, we’ll break it down to help you make an informed decision

What Are Electrical Terminals?

At its core, an electrical terminal is a device used to establish a connection between a wire and other electrical components, allowing electricity to flow between them. It provides a secure, efficient, and safe interface for connecting wires to a power source or an electrical device. Typically, terminals are made of conductive materials like copper or brass, which are then plated or coated to enhance their corrosion resistance and durability.

Terminals can come in various designs, each suited for different types of electrical systems. In many systems, these terminals are grouped on terminal blocks, which are modular components that allow multiple connections within a single insulated housing.

The most common method of attaching terminals to wires is through crimping—a process in which the terminal is compressed around the stripped end of the wire using a crimping tool. The crimp ensures a solid electrical and mechanical connection, which is crucial for reliable performance. Soldering is another method that can be used for certain applications, but crimping tends to be the preferred method in most modern wiring systems.

Types of Electrical Terminals

With so many different types of electrical terminals available, choosing the right one can be a daunting task. Below, we’ve outlined some of the most common terminal types, their characteristics, and typical applications.

Ring terminals are one of the most versatile and widely used types of electrical terminals. They feature a ring-shaped structure that allows a screw or bolt to pass through, securing the wire to the terminal. This design provides a stable and reliable connection, making ring terminals ideal for high-vibration environments, such as in automotive and heavy machinery applications. The ring ensures that the terminal stays in place even under mechanical stress, preventing accidental disconnections.

-

Spade Terminals (Fork Terminals)

Spade terminals, also known as fork terminals, have a forked end that allows for easy connection and disconnection from a bolt or screw. This design makes spade terminals an excellent choice for applications where frequent maintenance or modifications may be necessary. They are commonly used in bus bars and similar systems, as they allow new wires to be added without removing existing connections. Their simple design and ease of use make them a popular choice for various industrial and automotive applications.

-

Hook Terminals

With a hook-shaped design, hook terminals enable quick and secure connections without the need to remove a screw. This feature makes them perfect for installations in tight spaces where maneuverability is limited. Hook terminals are often used in situations where speed is crucial, and they provide a secure connection that can withstand mechanical stress. They are widely utilized in consumer electronics and other compact devices.

-

Quick-Disconnect Terminals

Quick-disconnect terminals, also known as quick-connect terminals, are designed for applications where frequent connections and disconnections are necessary. These terminals typically feature male and female components, with the male end sliding into the female terminal to create a reliable connection. Quick-disconnect terminals are commonly used in automotive, consumer electronics, and appliances where ease of maintenance and repair is required.

-

Bullet Terminals

Bullet terminals are designed with a cylindrical pole that fits into a hollow body, forming a tight and durable connection. This type of terminal is typically used in automotive and industrial applications, where the environment may involve exposure to harsh conditions like moisture, dust, or vibration. Bullet terminals are known for their ability to protect wires from external contaminants and maintain a secure connection in rough environments.

-

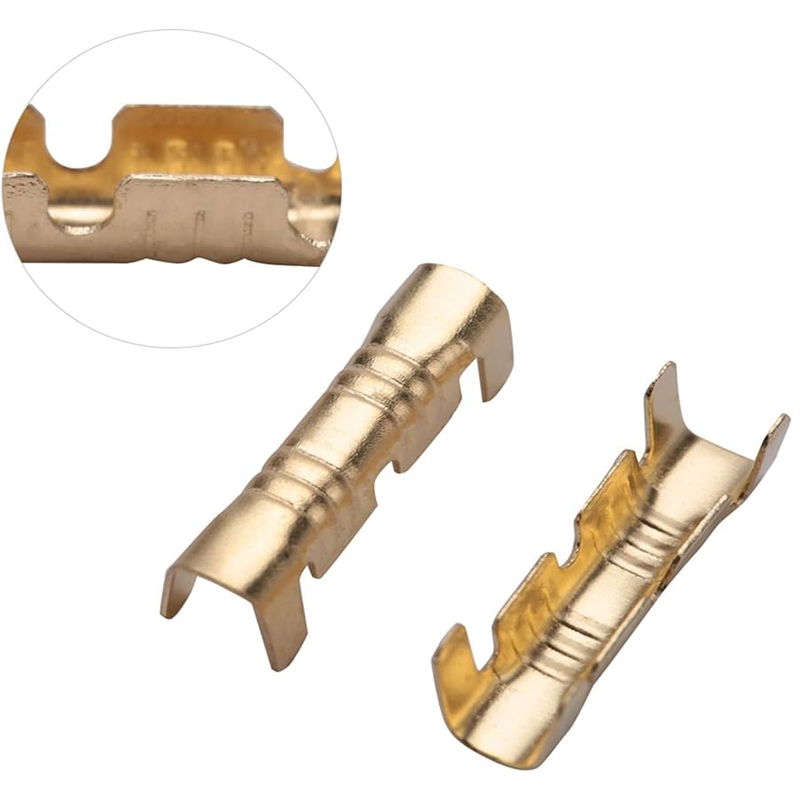

Butt Terminals

Butt terminals are used to connect two or more wires together securely. These terminals have open ends that allow wires to be inserted, and the ends are crimped to ensure a solid, permanent connection. Butt terminals are often used in applications where protection against moisture and corrosion is critical, such as in marine or outdoor electrical systems. They provide a reliable connection that can withstand environmental challenges.

-

Flag Terminals

Flag terminals are characterized by their unique flag-like shape, which allows for easy and secure connections in tight spaces. These terminals are particularly useful when working in confined or difficult-to-reach areas where other types of terminals may not fit. Their compact design allows them to be used in small electronic devices and other applications where space is at a premium.

Factors to Consider When Choosing the Right Terminal

Selecting the appropriate electrical terminal is more than just picking one that fits the wire. Several factors need to be taken into account to ensure the connection is secure, reliable, and safe for the intended application.

-

Material Selection

The material of the terminal is crucial in determining its performance. The most common materials used for electrical terminals include copper, brass, and aluminum. Copper is widely preferred for its excellent electrical conductivity, making it ideal for most applications. Brass offers good corrosion resistance and durability, while aluminum is often chosen for lightweight applications.

Terminals may also be plated or coated with materials such as tin, nickel, or gold to improve their resistance to corrosion and oxidation. When choosing a terminal, consider the material’s conductivity, durability, and corrosion resistance to ensure the best performance in your specific environment.

-

Wire Gauge Compatibility

Each terminal is designed to fit a specific wire gauge. It is essential to select a terminal that matches the wire size to ensure a secure connection. If the terminal is too large, the connection may not be tight enough, leading to poor electrical performance. If it is too small, the terminal may not accommodate the wire properly, leading to potential damage or disconnection. Many terminals are color-coded based on wire gauge to make selection easier.

-

Environmental Factors

The environment where the terminal will be used is another critical factor in selecting the right terminal. In high-vibration or harsh environments, you may need a terminal with a secure, tamper-resistant design, such as a ring terminal or bullet terminal. For applications exposed to moisture, salt, or other corrosive elements, terminals with special coatings or insulation may be necessary to prevent degradation.

-

Safety and Compliance

Make sure the terminal complies with relevant safety standards and certifications such as UL, CSA, or CE. These certifications ensure that the terminal has been tested and proven to meet safety, performance, and durability standards. Additionally, always check the current and voltage ratings of the terminal to ensure it can handle the load in your specific application.

Conclusion

Understanding electrical terminals and selecting the right one for your project is a crucial step in ensuring the success and safety of your electrical systems. Whether you are working with a simple wiring job or a complex circuit board, the correct terminal will ensure secure, efficient, and reliable connections.

By considering factors such as material, size, application environment, and compliance, you can make an informed decision that will enhance the overall performance and longevity of your electrical system. If you’re unsure about which terminal is best for your project, don’t hesitate to reach out to our team for expert guidance and recommendations.

Contact us today to learn more about the various types of electrical terminals and how we can help you select the perfect components for your next project.