In the world of precision manufacturing, stamping is a crucial process for producing a wide range of metal parts. Whether for automotive, electronics, or other industries, stamped components made from materials such as slit coil steel, copper, and brass are essential in the assembly of many products. These parts are manufactured using specialized stamping machines, each designed to meet different production requirements.

Among the most common types of stamping machines are progressive die stamping and multi-slide stamping. While both are used to transform raw material into precise stamped components, they each have distinct features, advantages, and limitations. Understanding these differences is crucial for selecting the best stamping process for your specific needs.

What is Progressive Die Stamping?

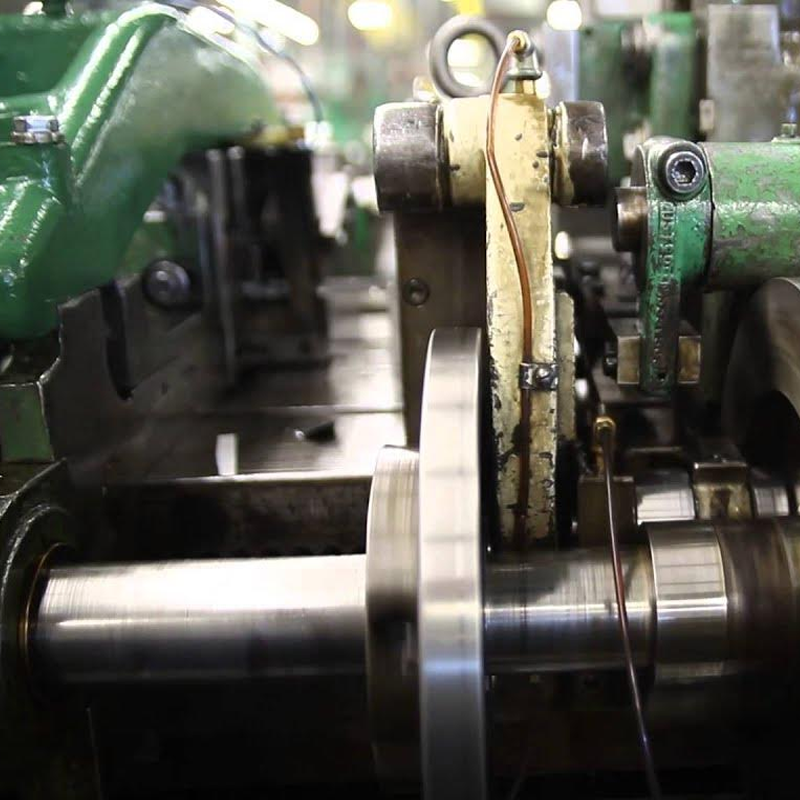

Progressive die stamping involves a series of operations performed on a single metal strip as it moves through a sequence of die stations. Each station performs a specific operation on the metal strip—such as cutting, bending, punching, or coining—until the final part is completed. This process is highly efficient for producing large volumes of parts with consistent precision.

The metal strip, typically fed from a slit coil, enters the first die station where the initial operation is performed. As the strip progresses through subsequent stations, additional modifications are made until the final part is completed. This multi-step process can range from a few steps to several dozen, depending on the complexity of the part design.

Key Benefits of Progressive Die Stamping:

- High Efficiency: Progressive die stamping is ideal for high-volume production runs. The automated system can produce large quantities of parts quickly while maintaining tight tolerances and high repeatability.

- Minimal Setup Time: Compared to multi-slide stamping, progressive die stamping generally requires less setup time, which translates to more flexibility in production scheduling and reduced labor costs.

- Precision: Each station in a progressive die press performs a specific function, ensuring the high accuracy of each component produced. This makes it suitable for parts that require tight tolerances.

- Flexible Tooling: The simplicity of progressive die tooling allows for relatively easy die changes. As long as the press has the same tonnage and bed size, tools can be moved between different presses without significant modifications.

Challenges of Progressive Die Stamping:

- High Initial Cost: One of the major drawbacks of progressive die stamping is the high cost of initial setup, particularly the cost of custom die sets. Businesses must produce a significant volume of parts to justify this expense.

- Limited Design Flexibility: Although progressive die stamping is great for high-volume, simple-to-moderately complex parts, it is not ideal for all types of designs. More intricate or detailed features may require different manufacturing processes.

- Waste Generation: Due to the need to keep parts attached to the metal strip throughout the entire stamping process, progressive die stamping can generate more waste material, especially with expensive metals like copper or brass. While this waste can be recycled, the costs may add up.

- Setup Complexity: Progressive die stamping requires careful setup and configuration. This makes it difficult to quickly switch between different part designs or projects, leading to longer lead times for job changes.

What is Multi-Slide Stamping?

On the other hand, multi-slide or four-slide stamping is a more versatile process that uses horizontal slides to form complex shapes and bends. Unlike progressive die stamping, which relies on a vertical motion of the metal strip, multi-slide stamping utilizes a series of dies mounted on multiple slides that move in horizontal directions. This motion allows for more intricate designs, especially when creating multi-part bends or precise geometries.

In this process, a coil of metal—usually wire or slit coil—enters the machine and is manipulated by a series of cams and dies. The parts are progressively shaped into their final form through multiple operations. The process is ideal for creating components with complex features that may require multiple bends or angles.

Key Benefits of Multi-Slide Stamping:

- Complex Shapes and Bends: Multi-slide stamping excels at producing parts with complex geometries, including multi-angle bends, cuts, or punches. It can handle shapes and designs that are difficult to achieve with progressive die stamping.

- High Precision and Repeatability: Multi-slide stamping offers excellent precision, especially when it comes to holding tight tolerances. With decades of experience, manufacturers like Keats have perfected this process to ensure consistently high-quality parts.

- Reduced Material Waste: Compared to progressive die stamping, multi-slide stamping generates less scrap. This is due to the absence of the need for pilot holes and the use of slotted blank holders, which allow parts to move from station to station without needing to remain attached to the strip.

- Faster Setup and Adjustments: Multi-slide machines can make quick adjustments to tooling without removing the die, resulting in less downtime and a faster production process. Additionally, these machines can be reconfigured to produce different parts with minimal setup changes.

- Flexibility in Materials: Multi-slide stamping is versatile enough to handle a wide variety of metal types, including thin and flexible materials. Additionally, the process is more flexible in terms of part design compared to progressive die stamping.

Challenges of Multi-Slide Stamping:

- Longer Setup Time: While multi-slide stamping offers flexibility, it can take longer to set up than progressive die stamping. The complexity of the machine and its dies requires careful configuration to ensure that all the required operations are performed correctly.

- Material Limitations: Multi-slide stamping is best suited for materials that are thin and flexible. For larger, thicker parts or certain materials, progressive die stamping may be a more effective choice.

- Specialized Equipment: Multi-slide stamping requires specific machinery, and the dies must be carefully designed to handle the horizontal slide motion. This can increase the complexity of the equipment and lead to higher initial costs.

Choosing the Right Stamping Process

When deciding between progressive die stamping and multi-slide stamping, it’s important to evaluate the specific requirements of your project. Progressive die stamping is ideal for high-volume runs of simple to moderately complex parts, offering excellent efficiency and repeatability. However, it may not be the best option for intricate designs or when flexibility is required.

On the other hand, multi-slide stamping is the go-to solution for parts that require complex geometries or multi-angle bends. It also reduces material waste and allows for faster adjustments, but it can be more time-consuming to set up and is better suited for thin, flexible materials.

Conclusion

Both progressive die stamping and multi-slide stamping offer distinct advantages and are integral to modern manufacturing. By understanding the strengths and limitations of each process, manufacturers can choose the most suitable option based on part complexity, volume, material type, and cost considerations. Whether you’re working with slit coil, wire stock, or more specialized metals, it’s essential to work with an experienced stamping partner like Topmetalstamping, who can provide expert guidance and ensure that the right solution is applied to your project.

If you need assistance with your stamping needs or want to learn more about which method is right for your product, contact us at Topmetalstamping today. We offer comprehensive solutions for custom metal stamping, and our experienced team can help you optimize your production process for maximum efficiency and cost-effectiveness.