Overview

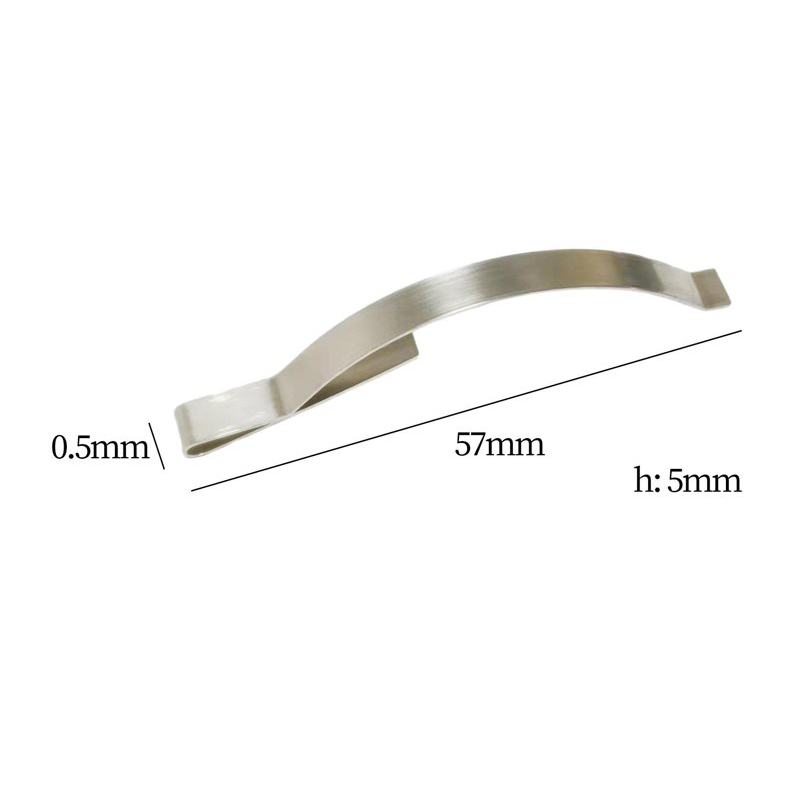

Metal window screen clips are small, durable fasteners used to securely attach window screens to their frames. Typically made from galvanized steel or stainless steel, these clips prevent screens from being dislodged by wind or external forces. They are easy to install and offer a strong hold, ensuring that the screen stays in place while allowing for proper ventilation and insect protection. Ideal for both residential and commercial use, these metal clips are a practical solution for maintaining secure and functional window screens.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Customization Services for Metal Stamping Parts

– Design and Engineering: We offer comprehensive design and engineering services to tailor metal stamping parts to your specific requirements. Our team utilizes advanced CAD software and technical expertise to develop precise designs that meet your operational needs.

– Material Selection: Choose from a wide range of high-quality metals and alloys suitable for various applications. We ensure that the materials used align with your performance and durability requirements.

– Prototyping: We provide prototyping services to validate designs and functionality before full-scale production. This step ensures that the final product meets all specifications and quality standards.

– Tooling and Die Creation: Our precision tooling and die creation process ensures accurate and consistent part production. We use advanced machinery to fabricate tools that enhance production efficiency.

– Production: Utilizing state-of-the-art metal stamping technology, we produce parts with high precision and consistency. Our facilities are equipped to handle both small and large production runs.

– Quality Control: Each part undergoes rigorous quality control checks to ensure it meets the highest standards. We perform dimensional inspections, functionality tests, and material evaluations to guarantee reliability.

– Finishing and Surface Treatment: We offer a range of finishing options, including electroplating and polishing, to enhance the appearance and performance of your parts.

– Packaging and Delivery: Customized packaging solutions ensure that your parts are securely transported and delivered on time. We coordinate logistics to meet your scheduling needs.

– After-Sales Support: Our commitment extends beyond delivery. We provide ongoing support to address any issues and ensure customer satisfaction with our products.

Quality Control

Quality is our foremost priority. At the outset of each project, we conduct a feasibility review of the metal parts to ensure manufacturability. We also perform a run-at-rate study during the initial production run to validate quality before proceeding to large-scale manufacturing. This allows our quality and production management teams to closely monitor controls and ensure smooth operations. Once testing is completed successfully, we proceed with the production of the first batch of conforming metal parts.

Our quality management system is built on advanced technology and controls, continuous improvement initiatives, and a state-of-the-art quality laboratory and team. Throughout our production facility, we utilize in-line and off-line camera vision systems and sensor technology, customized for each production program. Our vision system technology integrates with our stamping machinery to meticulously inspect and verify part features and dimensions using automated camera imaging. This rigorous quality control process guarantees that every metal part produced meets our high standards, ensuring 100% quality and zero defects.

Reviews

There are no reviews yet.