Description:

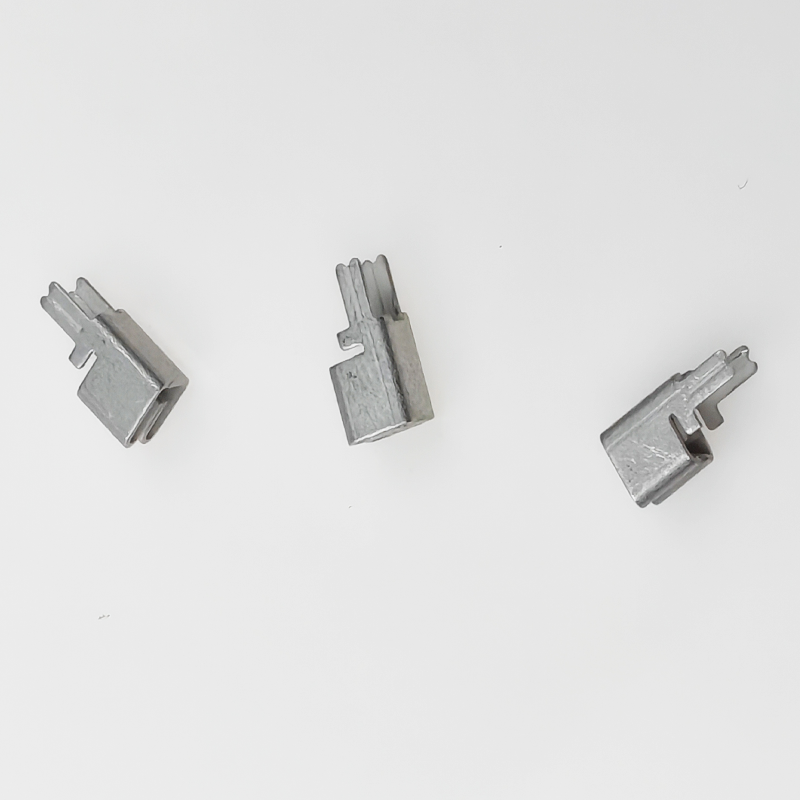

Our custom metal terminals are engineered for high-performance applications, using premium-grade materials to guarantee durability and reliability. Manufactured through a precision stamping process, each terminal is crafted to maintain precise shape and dimensions, ensuring optimal functionality. We also employ advanced CNC machining techniques to achieve exceptional accuracy, down to the finest details. The integration of these advanced technologies ensures our products perform reliably in demanding environments, providing stable operation over extended periods.

Features:

| Feature | Details |

| After-sales Service | Yes |

| Processing Type | Shaping Metal |

| Materials | Copper, Stainless Steel, Brass, Aluminum, Phosphor Bronze, Titanium |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Yes |

| Multi-Position | Yes |

| Tolerances | 0.02 mm |

| Customized | Yes, warmly welcome |

| Lead Time | 10-20 Days |

| Prototype Process | SLA, Vacuum Forming, CNC, etc. |

| Sample Time | 3-7 Days |

| Trademark | OEM |

| Specification | Customized |

| Origin | China |

Quality Control for Our Terminals:

At Topmetalstamping, we prioritize the highest standards of quality in every part we produce. Our rigorous quality assurance process begins with a comprehensive feasibility review, ensuring that each part is manufacturable from the outset. Before moving into full-scale production, we conduct a run-at-rate study during the initial run to verify quality standards are met. This allows our quality and production teams to closely monitor controls and ensure smooth operation throughout the manufacturing process. Once the testing phase is complete and the first batch of parts meets the required specifications, production proceeds.

Our quality management system is built on advanced technology, continuous improvement initiatives, and a dedicated quality laboratory. Throughout our facility, we employ both in-line and off-line camera vision systems, as well as sensor technologies custom-designed for each production run. These systems work in tandem with our stamping machinery, utilizing automated camera imaging to thoroughly inspect part features and dimensions. This precise quality control process ensures that every part produced meets our strict standards, guaranteeing 100% quality and zero defects.

Elevate your application with high-performance terminals manufactured to the highest quality standards. With a skilled team, cutting-edge technology, and a commitment to excellence, we ensure reliable, defect-free products delivered on time.

Surface Treatment Options:

-

Electroplating

A process where a metal coating is applied to the surface of the terminal through electrochemical deposition, enhancing its corrosion resistance and improving conductivity.

-

Nickel Plating

Provides a durable and corrosion-resistant finish, offering improved wear resistance and enhanced protection against environmental factors.

-

Gold Plating

Often used for high-performance applications, gold plating offers excellent conductivity, corrosion resistance, and a low-contact resistance, making it ideal for precision electronics.

-

Tin Plating

Offers a cost-effective option that provides protection against oxidation and corrosion while maintaining good electrical conductivity.

Why Choose Us?

- Dedicated R&D Team– Focused on process optimization and cost reduction through continuous innovation and improvements.

- In-House Tooling and Die Design– We handle the entire process of stamping die and tooling design and manufacturing internally, ensuring complete control over quality and efficiency.

- Rigorous Quality Control– Our operations strictly adhere to ISO 9001 and IATF 16949 standards, ensuring consistent, high-quality production across all stages.

- Comprehensive Inspection Process– Every product undergoes a thorough 100% inspection before shipment, ensuring reliability and conformity to specifications.

- Timely Delivery– We guarantee on-time delivery, including the capability to accommodate urgent orders with fast turnaround.

Reviews

There are no reviews yet.