Overview

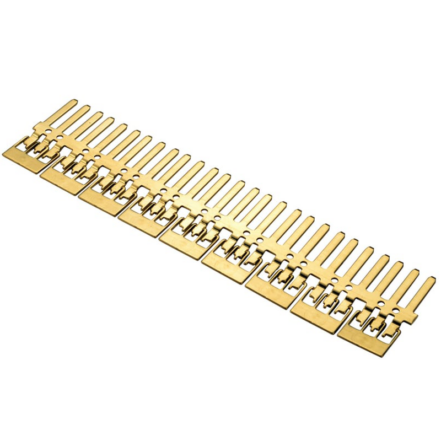

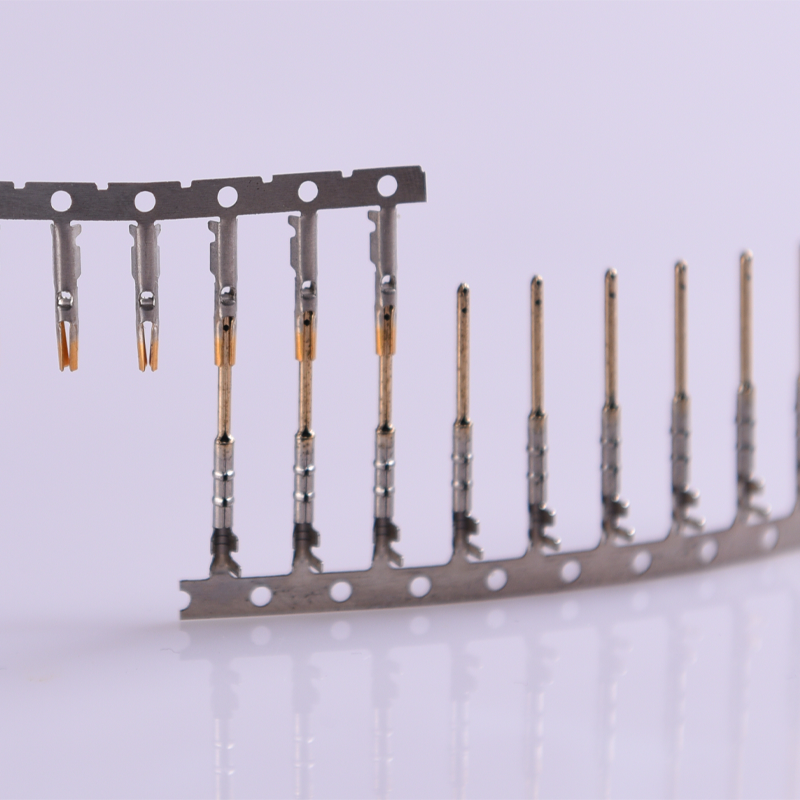

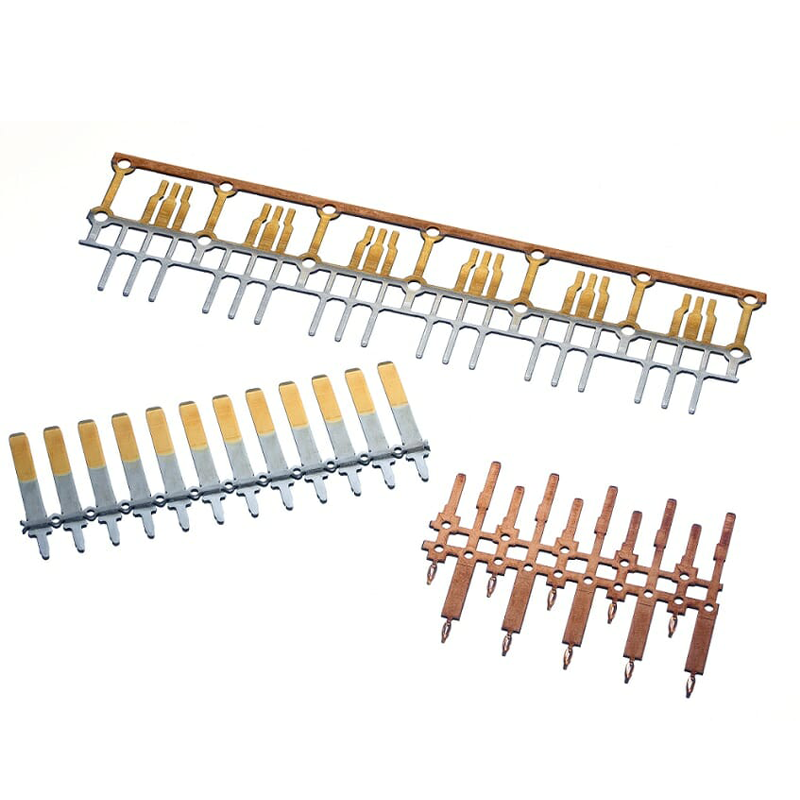

Stamped connectors are electrical components made through a stamping process, where metal sheets are cut, shaped, and formed into precise connector parts. These connectors are commonly used in various industries, including automotive, electronics, and industrial applications, to establish reliable electrical connections between components. Stamped connectors are cost-effective, lightweight, and offer high durability and conductivity. They are ideal for applications requiring efficient space utilization and high-volume production. These connectors can be customized for different sizes, shapes, and configurations to meet specific design and performance needs.

Basic Information:

- Material:Copper-5191

- Post Process:Gold plating, Silver plating, Nickel-plating, Tin plating

- Surface Finish Options:Gold Plating, Silver Plating, Nickel Plating, Tin Plating

- Sample Availability:Available

- Tolerance:±0.001 mm

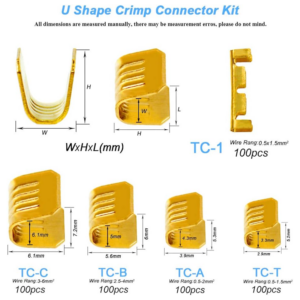

- Size:Customizable as per requirement

- Manufacturing Approach:Metal Stamping, Cutting, Punching, Bending, Welding

- Transport Packaging:OPP Bag, Box, or Custom

- Specification:Customized

- Origin:Xiamen, China

- Applications:Consumer electronics (smartphones, laptops), automotive (engine control, lighting), industrial automation (PLCs, robotic systems), telecommunications (routers, base stations), medical equipment (diagnostic tools, imaging), aerospace (satellite communications, avionics), energy & power (solar inverters, wind turbines).

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.

Advantages of Our Product

-

Precision Engineering

– Our metal stamping parts are crafted with high precision, ensuring exact dimensions and consistent quality for optimal performance.

-

High Durability

– Utilizing robust materials and advanced stamping techniques, our parts exhibit superior strength and durability, suitable for demanding applications.

-

Cost-Effective Productio

– The efficiency of our stamping processes minimizes material waste and reduces production costs, offering economical solutions for large-scale manufacturing.

-

Rapid Production Turnaround

– Our state-of-the-art equipment and streamlined processes enable quick production cycles, meeting tight deadlines and high-volume demands.

-

Versatile Applications

– Our metal stamping parts are versatile and can be customized to fit a wide range of industries including automotive, aerospace, and industrial applications.

Reviews

There are no reviews yet.