Overview

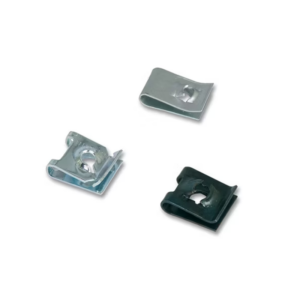

Car air control button shrapnel metal stamping clips are precision-engineered components used in automotive air conditioning and climate control systems. These clips, made from durable metal, are designed to securely hold and connect air control buttons within the vehicle dashboard. Manufactured using a metal stamping process, they offer high strength, excellent durability, and precise fitting. The shrapnel clips ensure smooth operation of air control buttons, providing a reliable mechanical connection that withstands the vibrations and temperature fluctuations typical in automotive environments. These clips are an essential part of ensuring the longevity and functionality of automotive interior systems.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Passivation, Golden plating, silver plating, nickel plating, tinplating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Automotive

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Advantages of Our Product

High Quality

We specialize in OEM services for leading brands in metal stamping parts, ensuring superior quality.

Processing Speed

Our team of professionals and advanced machinery enable us to significantly shorten delivery times.

Drawing Acceptance

We accept drawings in all formats and ensure high-precision production according to your specifications.

Technology Innovation

We offer design services and technical support to help solve complex problems and drive innovation.

The Production Process for Our Metal Stamping Parts:

-

Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

-

Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

-

Material Preparation

– Select and prepare metal sheets according to the required specifications.

-

Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

-

Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

-

Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

-

Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

-

Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

-

Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

-

After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

Reviews

There are no reviews yet.