Overview:

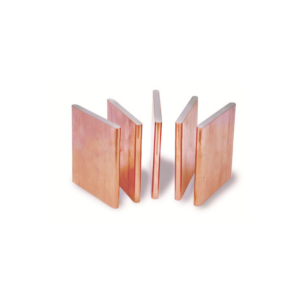

Metal sleeves are engineered to ensure precise component alignment, reduce wear, and minimize friction between two surfaces in motion. Commonly used as guides in precision metal drilling applications, these components help maintain accuracy. As a type of bearing, metal sleeves are distinct from other bearings due to their simple design, which lacks rolling or ball elements. While typically single-piece components, metal sleeves can be customized with multiple layers of conductive or insulating materials or lubricated, depending on the specific requirements of the application.

We offer OEM custom metal sleeves, tailored to meet your unique needs, including material selection, coating, and lubrication options. Our advanced manufacturing processes ensure superior performance and reliability for a wide range of applications. Contact us today for bespoke solutions that enhance your product’s efficiency and longevity.

Characteristics:

| Attribute | Details |

| Material | Stainless Steel |

| Certifications | ISO9001, RoHS, SGS, IATF16949 |

| Material Hardness | 45-50 HRC or as per request |

| Surface Treatment | Zinc, Nickel, Chrome, Powder Coating, or Customized |

| Material Capabilities | Aluminum, Copper, Brass, Stainless Steel, Steel |

| Color | Customized Color |

| Service | Customization, OEM |

| Shape | Custom |

| Quality Control | 100% Inspection |

| Transport Package | PE Bag + Carton Box or Customized |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

Advantages of Our Metal Sleeves:

- Reduced Weight

- Cost-Effective

- Enhanced Load-Bearing Capacity

- Superior Shock Load and Vibration Resistance

- Improved Tolerance to Shaft Misalignment

Production Process:

-

Material Selection and Preparation

– High-quality materials such as stainless steel, aluminum, or brass are carefully chosen for their durability and conductivity, then prepared in sheet or coil form for processing.

-

Tooling and Die Setup

– Custom tooling and dies are designed and set up based on the specific dimensions and design requirements of the metal stamping sleeves.

-

Stamping and Forming

– Precision stamping presses shape the material into the desired sleeve design, ensuring exact dimensions and structural integrity.

-

Surface Treatment

– The stamped sleeves undergo surface treatments like plating, powder coating, or anodizing to enhance durability, corrosion resistance, and appearance.

-

Quality Control and Inspection

– Each batch of sleeves is rigorously inspected for dimensional accuracy, surface finish, and functionality to meet strict quality standards.

-

Packaging and Delivery

– Finished metal stamping sleeves are securely packaged and prepared for shipment, ensuring safe delivery in optimal condition.

Why Choose Us?

- Customized Drawings and Specifications

- Material Selection

- Order Quantity and Sample Confirmation

- Contract Finalization and Proofing Fee

Our Factory:

We operate a state-of-the-art manufacturing facility equipped with a full range of advanced machinery to ensure superior production quality. Our plant houses 25 punch presses, with capacities ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding tools, welding and polishing stations, and ultrasonic cleaning systems.

Beyond our core manufacturing capabilities, we provide a comprehensive suite of metal plating services to enhance the performance, appearance, and longevity of our stamped metal products. These services include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our advanced plating lines are designed to deliver consistent coatings, superior corrosion resistance, and full compliance with industry standards.

The integration of highly skilled operators, cutting-edge automation, stringent quality control processes, and high-end plating techniques ensures that we consistently deliver metal stamping products that meet the highest industry standards.

Reviews

There are no reviews yet.