Overview:

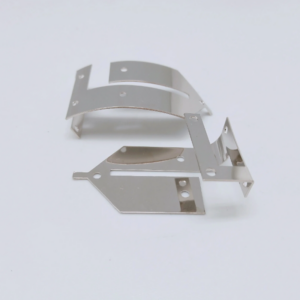

Aluminum Metal Stamping Electrical contacts are precision components made from high-quality aluminum through advanced stamping processes. These contacts ensure reliable electrical connections with excellent durability and corrosion resistance.We offer custom solutions tailored to specific requirements, including size, material, and surface treatments. These contacts are commonly used in automotive, electronics, telecommunications, and power distribution industries, where dependable electrical performance is essential.Contact us for custom aluminum contacts to optimize your electrical systems.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Shape | Custom Designs |

| Logo | Accept Customized Logo |

| Process | CNC Machining, Stamping, Milling, Sheet Metal |

| Service | Customized OEM |

| Surface Treatment | Painting, Powder Coating, Plating, Polishing |

| Standard | ISO9001:2015 |

| Material | Aluminium |

| Delivery Time | Based on Order Quantity |

| Color | Customized Color |

Quality Control Process:

The quality control process for Aluminum Metal Stamping Electrical contacts involves several key steps to ensure each component meets the highest standards of performance and reliability. The process begins with material inspection, where incoming aluminum materials are verified for quality and compliance with specifications. Next, in-process monitoring is conducted during the stamping and machining phases, using equipment such as CMM (Coordinate Measuring Machines), calipers, and micrometers to ensure precise dimensions and tolerances. Following production, visual inspection and functional testing are performed to identify any defects or irregularities. For additional assurance, salt spray testing and electrical conductivity tests are carried out to evaluate corrosion resistance and the quality of electrical connections. Finally, the finished contacts undergo a final inspection before being packaged, with 100% inspection to ensure each product meets the required standards for durability and functionality. This rigorous process, combined with the use of advanced quality control equipment, ensures the consistent reliability of our aluminum metal stamping electrical contacts.

Why Choose Us?

-

Advanced R&D Capabilities

Our dedicated R&D team continually drives innovation to improve manufacturing processes, reduce costs, and enhance product performance, ensuring we stay ahead of industry trends.

-

End-to-End Tooling and Die Development

By handling the complete tooling and die design and production process internally, we ensure precise control over quality, accuracy, and operational efficiency throughout every project.

-

Rigorous Quality Assurance

Compliant with ISO 9001 and IATF 16949 standards, our stringent quality assurance protocols guarantee consistent, high-quality outcomes at every production stage.

-

Comprehensive Product Inspection

We conduct thorough 100% inspections on all products before shipment, ensuring each item meets exact specifications and delivers exceptional durability and reliability.

-

On-Time, Dependable Delivery

We pride ourselves on meeting delivery deadlines, offering expedited production for urgent orders to ensure our clients consistently receive their products on schedule.

Our Factory:

We operate a state-of-the-art manufacturing facility equipped with an extensive range of advanced equipment to ensure the highest standards of production quality. Our plant houses 25 punch presses, ranging from 25 tons to 300 tons, precision wire EDM machines, grinding stations, welding and polishing tools, as well as ultrasonic cleaning systems, all designed to deliver superior results.

In addition to our robust manufacturing capabilities, we provide a variety of metal plating services to enhance the durability, aesthetics, and functionality of our metal stamping products. These processes include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities are equipped to produce consistent finishes, improve corrosion resistance, and meet or exceed industry standards.

This combination of professional-grade equipment, automated production lines, stringent quality control protocols, and advanced plating techniques allows us to consistently deliver metal stamping products that meet the highest levels of precision and performance.

Reviews

There are no reviews yet.