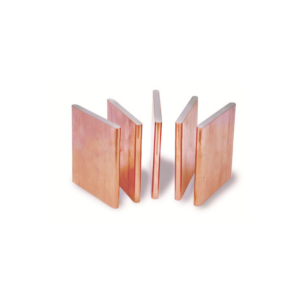

Description:

An aluminum 5052 deep drawing metal bushing is a high-precision component made from durable Aluminum 5052 alloy, which is known for its excellent corrosion resistance, strength, and formability. These bushings are typically used in industries such as automotive, aerospace, marine, and machinery, where reliability and performance are critical. They are commonly used as wear-resistant components in mechanical systems, offering smooth operation and long service life. Featuring superior quality and durability, our factory provides custom production services, offering a wide range of sizes, materials, and surface treatments to meet specific application requirements. Whether you need unique dimensions, specific alloy types, or specialized finishes, we can deliver tailored solutions to suit your needs.

Characteristics:

| Item | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| CNC Machining | CNC Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Stainless Steel, etc. |

| Process | Deep Drawing |

| Quality Control | 100% inspection of products |

| MOQ | Small orders can be accepted |

| Tolerance | +/-0.002-0.01mm |

| Service | Packaging, Assembly services |

| Logo | Custom Logo accepted |

Production Process:

-

Material Selection

The process begins with selecting high-quality Aluminum 5052 alloy, which is known for its excellent corrosion resistance, formability, and strength, making it ideal for deep drawing applications.

-

Blanking

A flat sheet of Aluminum 5052 is cut into the desired shape, known as the “blank,” which is the precursor to the deep drawing process. The size and shape of the blank are critical to ensuring proper forming during the next steps.

-

Deep Drawing

The blank is placed into a deep drawing press, where a punch and die are used to form the metal into a cylindrical or bushing shape. The material is stretched and drawn into the desired depth while maintaining the integrity of its structure. This step requires precise control to avoid material thinning or defects.

-

Trimming

After the deep drawing process, excess material is trimmed off to achieve the final shape and size of the bushing. The trimming ensures uniform edges and prepares the part for the next stage.

-

Surface Finishing

Depending on the application, the bushing may undergo additional surface treatments such as anodizing, polishing, or coating to improve its appearance, corrosion resistance, or wear properties.

-

Quality Inspection

The bushings are carefully inspected for dimensional accuracy, surface quality, and overall integrity. Tolerances are measured using precision tools to ensure each part meets strict specifications.

-

Packaging and Delivery

Finally, the aluminum bushings are packaged to prevent damage during transportation and are prepared for delivery, with customized packaging options available based on customer requirements.

Surface Treatments:

– Passivation

A chemical treatment process applied to stainless steel and other metals to enhance corrosion resistance by forming a protective oxide layer on the surface. This treatment improves the durability and longevity of metal components, especially in harsh environments.

– Anodization

An electrochemical process that thickens the natural oxide layer on the surface of aluminum, enhancing its corrosion resistance, wear resistance, and aesthetic appearance. Anodized surfaces can also be dyed for decorative purposes.

– Nickel Plating

The application of a thin layer of nickel onto the surface of metal components through electroplating. This process improves corrosion resistance, wear resistance, and provides a uniform finish, making it suitable for components exposed to high-stress environments.

– Tin Plating

A process where a thin layer of tin is electroplated onto a metal surface to provide corrosion resistance, improve solderability, and enhance the component’s overall performance, particularly in electronics and electrical applications.

Factory Show:

We operate a fully-equipped facility with a wide range of advanced machinery to maintain the highest standards of production quality. Our plant features 25 punch presses with capacities ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

Beyond our robust manufacturing capabilities, we also offer a comprehensive suite of metal plating options to enhance the durability, appearance, and performance of our stamped metal products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure consistent, high-quality finishes, superior corrosion resistance, and full compliance with industry regulations.

By combining automated production lines, state-of-the-art equipment, strict quality control protocols, and top-tier plating services, we consistently deliver metal stamping products that meet the highest quality standards.

Reviews

There are no reviews yet.