Description:

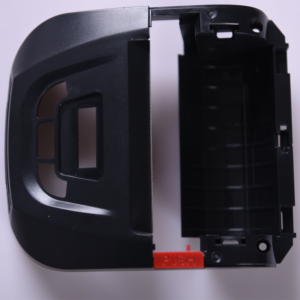

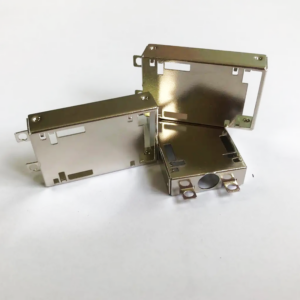

The SUS304 Stamped Shield Case for Electrical Applications is an expertly crafted enclosure designed to deliver superior electromagnetic interference (EMI) shielding and protection for sensitive electrical components. Constructed from high-quality SUS304 stainless steel, known for its excellent corrosion resistance and durability, this shield case is produced using precision stamping to ensure exceptional accuracy and reliability.

Our manufacturing capabilities offer customized solutions for SUS304 stamped shield cases, with tailored options for size, material, and surface treatment such as powder coating, plating, or anodizing. Whether you require standard or bespoke designs, we provide OEM services to meet your precise specifications and ensure high-quality, durable protection for your electrical components.

Details:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Standard: ROHS, ISO9001

- Application: Electrical Applications

- Color: Customized Colors

- Size: Customized Size

- MOQ: Accept Small Order

- Packing: Custom

- Delivery Time: 7-15 Working Days

- Sample: Available

- Quality Control: 100% Inspection

Surface Treatments:

- Powder Coating: Provides a durable, corrosion-resistant finish with a smooth, attractive appearance.

- Electroplating: Adds a thin metal layer (e.g., nickel or gold) for improved durability, conductivity, and corrosion resistance.

- Anodizing: Enhances corrosion resistance and wear resistance while offering customizable color finishes.

- Passivation: Improves corrosion resistance by removing free iron and promoting a protective oxide layer.

Production Process:

- Material Selection: High-quality SUS304 stainless steel is chosen for its excellent corrosion resistance, strength, and formability, making it ideal for electrical shielding.

- Stamping: The material is fed into precision progressive dies or single-stroke stamping presses, where it’s shaped and cut into the desired shield case form. This process ensures high precision and consistency across large production runs.

- Bending: After stamping, the case is carefully bent to meet the required shape and dimensional specifications. This is typically done using CNC bending machines to ensure accuracy.

- Surface Treatment: The stamped shield cases undergo a surface treatment process, such as powder coating, electroplating, anodizing, or passivation, to improve their appearance, corrosion resistance, and performance in electrical applications.

- Assembly (if required): If the shield cases need to be combined with other components, an assembly process is carried out. This could include installing mounting hardware, fasteners, or additional shielding materials.

- Quality Control: Each unit is rigorously inspected using both manual and automated testing methods to ensure they meet the required specifications for size, strength, surface finish, and electrical performance.

- Packaging and Shipping: The completed SUS304 stamped shield cases are carefully packed according to customer specifications, ensuring they are protected during transportation and ready for immediate use in electrical applications.

Factory Show:

We maintain a fully equipped facility to ensure top-tier production quality, featuring 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. Our comprehensive capabilities extend to a variety of advanced metal plating processes, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all designed to enhance the durability, appearance, and performance of our metal stamping products. With automated production lines, cutting-edge machinery, stringent quality control measures, and high-quality plating facilities, we consistently deliver metal stamping products that meet the highest industry standards.

Reviews

There are no reviews yet.