At Topmetalstamping, we specialize in high-precision metal stamping for a variety of industries, from automotive to electrical applications. Since our inception in 1998, we’ve been helping businesses bring their most complex designs to life by providing customized stamping solutions. One of the most critical decisions when starting a new project is selecting the right material, as it directly influences the performance, durability, and overall quality of the final product. Whether you’re manufacturing simple components or intricate parts, the material you choose can make all the difference.

The Importance of Material Selection in Metal Stamping

Each material has its own unique properties, and these characteristics determine how well a material will perform in a specific application. At Topmetalstamping, we focus on providing our clients with the best possible material options, ensuring that each part is tailored for its intended use. Here, we discuss the most commonly used materials for metal stamping, highlighting their advantages and best-use applications.

-

Copper

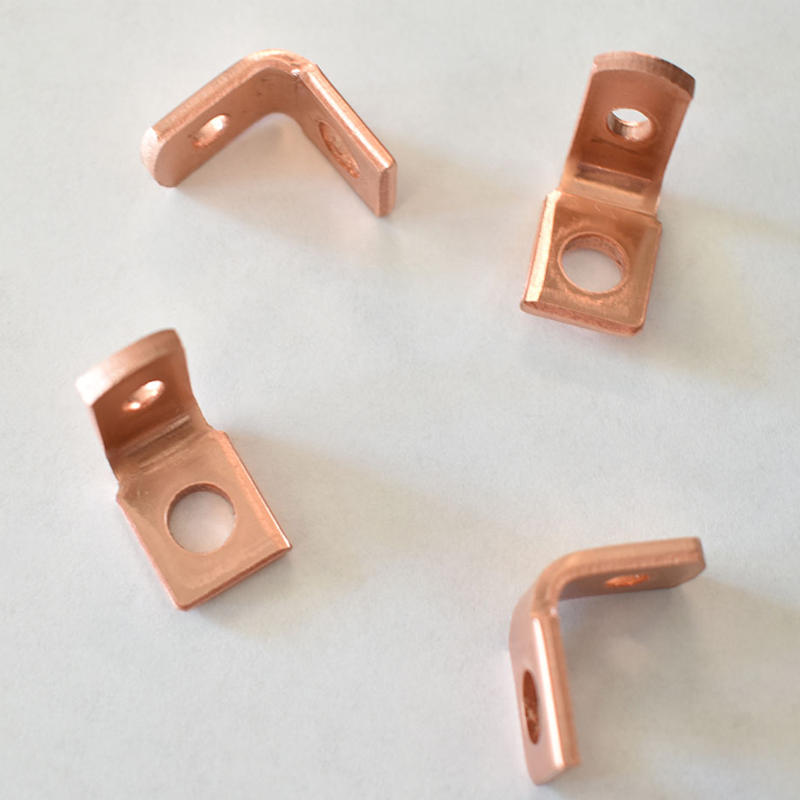

Copper is renowned for its excellent electrical conductivity, second only to silver and gold. As a result, it is often the go-to choice for electrical components where high conductivity is a must. Copper is highly corrosion-resistant, particularly in industrial environments, water, and non-oxidizing acids. Over time, copper forms a protective oxide layer that prevents further corrosion, ensuring longevity even in harsh conditions.

Copper’s malleability and ductility also make it ideal for precision stamping, particularly when fine details and tight tolerances are required. For automotive and electrical parts, copper is typically used in thicknesses ranging from 0.010” to 0.050”. Topmetalstamping uses a variety of copper alloys such as C102, C110, C122, C194, and C197 to meet specific customer requirements, with notable applications including reel-to-reel terminals, conductive lead frames, and wire forms.

-

Phosphor Bronze

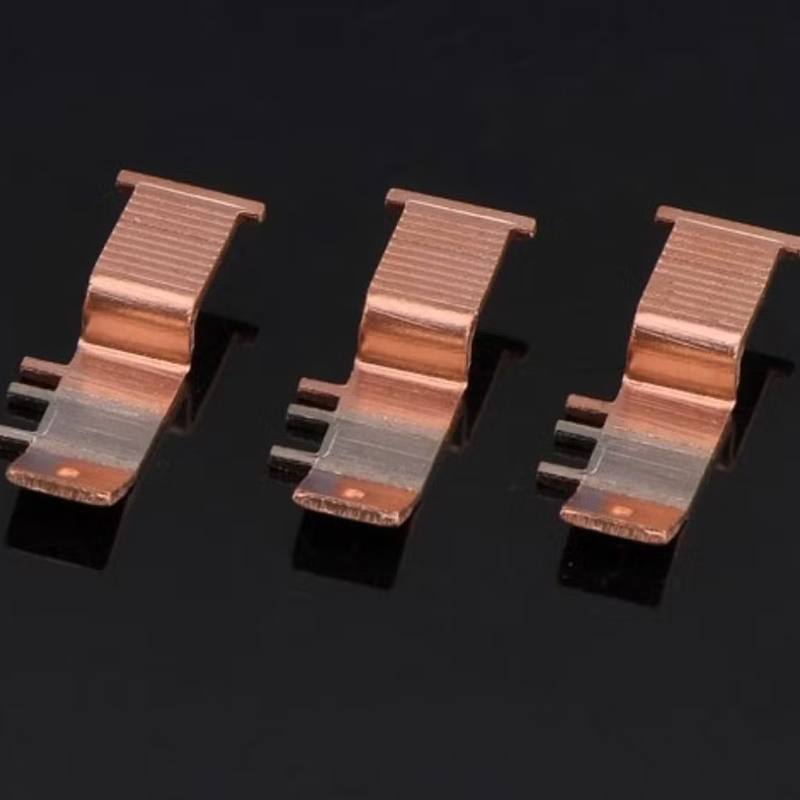

Phosphor bronze is an alloy of copper, tin, and phosphorus. It offers a unique combination of toughness, strength, and low friction, making it a preferred material for parts that will endure heavy use or frequent movement. While it doesn’t match copper’s conductivity, phosphor bronze is highly resistant to stress corrosion cracking and offers excellent resistance to seawater and industrial environments.

This material is widely used for springs, bolts, contacts, and other components that require high strength and low thermal conductivity. It performs best at thicknesses ranging from 0.008” to 0.050”, and its ability to maintain integrity under stress makes it ideal for applications where fatigue resistance is crucial. Some of the alloys we use at Topmetalstamping include C510, C511, C519, and C521.

-

Brass

Brass, an alloy of copper and zinc, is often the most economical choice for electrical applications due to its lower cost compared to pure copper. Brass combines the best properties of both copper and zinc, offering good malleability, resistance to corrosion, and excellent machinability. It’s also more aesthetically pleasing, which is why it’s often chosen for decorative applications.

While its electrical conductivity is not as high as copper (about 28%), brass is an excellent choice for a wide range of applications, including reel-to-reel terminals, contacts, and lead frames. The material also boasts good resistance to moisture, industrial atmospheres, and chemicals. Topmetalstamping uses alloys such as C210, C220, C230, and C260 to deliver parts that meet both performance and cost objectives.

-

Aluminum

Aluminum is one of the most commonly used materials in metal stamping, and for good reason. Known for its exceptional strength-to-weight ratio, aluminum is ideal for applications where lightweight components are crucial without compromising on strength. It’s also naturally corrosion-resistant, making it suitable for outdoor or marine environments.

Aluminum is highly versatile, offering both thermal and electrical conductivity, as well as good resistance to most chemicals and moisture. Its malleability and ease of forming make it a popular choice for automotive components, wire forms, brackets, and covers. The typical thickness range for aluminum stamping is 0.012” to 0.120”, and at Topmetalstamping, we use alloys such as 3003, 1100, and 5052 to ensure high-quality results.

-

Steel

Steel remains one of the most widely used materials for metal stamping due to its remarkable versatility. Steel alloys, such as cold-rolled, annealed, and stainless steel, offer a wide range of mechanical properties, making them suitable for countless applications. Steel is tough, durable, and resistant to corrosion, but its properties can vary depending on the specific alloy and heat treatment process used.

At Topmetalstamping, we use various steel grades, including G1050, AISI 304 (stainless steel), and C1010, each chosen for their specific attributes. Steel is commonly used for structural components, brackets, and contacts in automotive, electrical, and industrial applications. The material is particularly popular for parts requiring high strength and durability.

Why Material Selection Matters for Your Project

The material you choose has a profound impact on your part’s performance, cost-effectiveness, and longevity. At Topmetalstamping, we understand that selecting the right material is critical to your project’s success. Our team works closely with clients to evaluate their requirements, from environmental considerations to performance expectations, ensuring that the material chosen aligns perfectly with the intended application.

The Topmetalstamping Advantage

As a leading provider of custom metal stamping solutions, Topmetalstamping offers unmatched expertise in material selection, design, and production. With over 20 years of experience in the industry, we have developed strong relationships with suppliers and access to a broad range of materials to meet even the most specific project needs.

Our comprehensive production capabilities include 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding tools, and ultrasonic cleaning systems, all of which help ensure the highest level of accuracy and quality. We also offer a variety of metal plating options, including electroplating, nickel plating, and anodizing, to enhance the durability and appearance of your parts.

Whether you require reel-to-reel terminals, custom components, or complex assemblies, Topmetalstamping is committed to delivering superior products that meet the highest industry standards.

Ready to get started?Selecting the right material is just the first step in your metal stamping journey. If you’re ready to discuss your project, or if you need expert guidance on material selection, contact us at Topmetalstamping. Our dedicated team is here to help you choose the best materials for your specific needs and guide you through every step of the production process. Reach out today to request a quote or learn more about how we can support your next project.