Overview

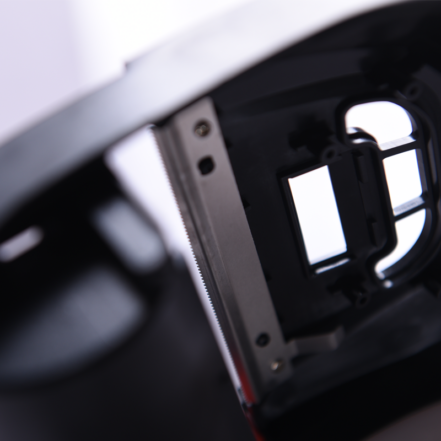

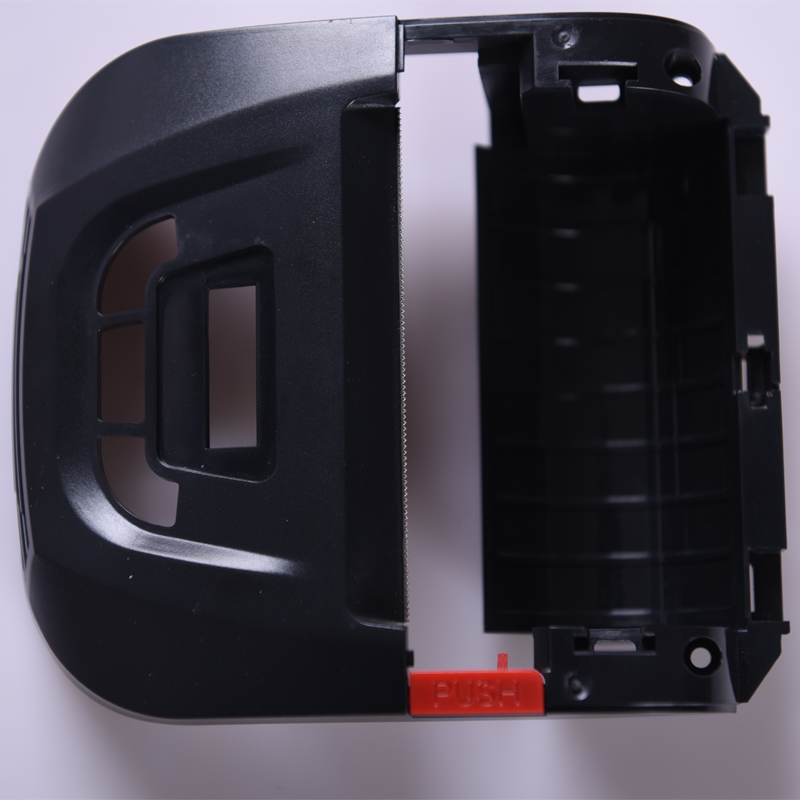

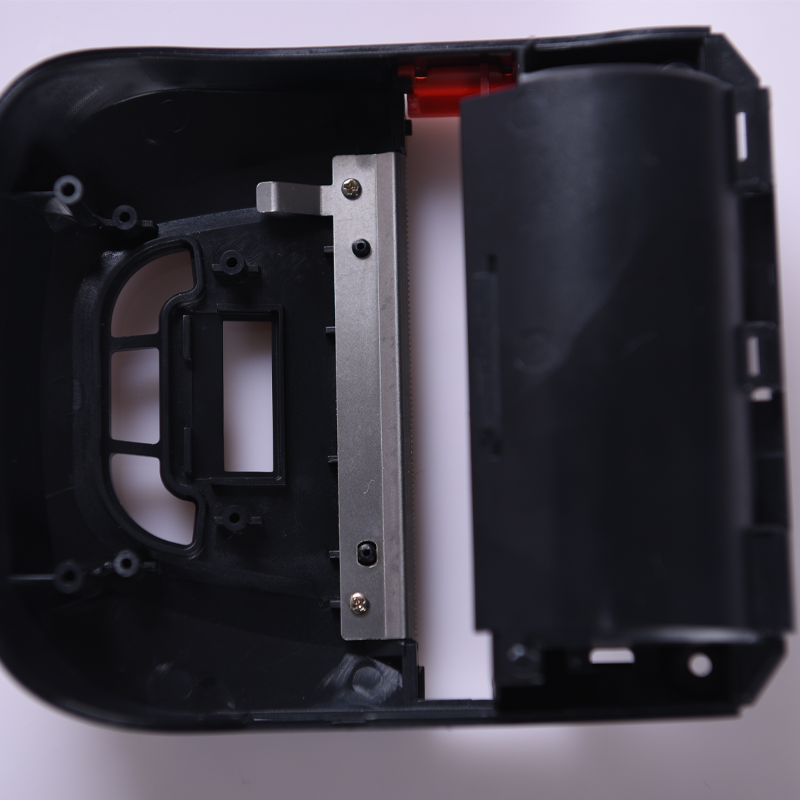

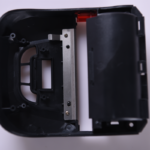

The POS plastic enclosure panel assembly is a high-quality, durable component designed for Point of Sale (POS) systems. Made from robust plastic materials, this assembly features a secure and ergonomic panel that houses and protects the internal electronics. It is carefully engineered for easy installation and long-term use, ensuring optimal performance in retail or commercial environments. With precise design and manufacturing, this POS panel assembly meets the highest standards of reliability and functionality.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.

Surface Treatments for Metal Stamping Parts

-

Electroplating

– Description: A process that deposits a layer of metal onto the surface of the part using an electric current. Commonly used for improving corrosion resistance and enhancing appearance.

– Types: Nickel plating, chrome plating, zinc plating.

-

Powder Coating

– Description: A dry coating process where powdered paint is electrostatically applied and then cured under heat. It provides a durable, high-quality finish with excellent resistance to scratches, chipping, and fading.

-

Anodizing

– Description: An electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant layer. Anodizing also enhances appearance and can be dyed in various colors.

-

Plating

– Description: The application of a thin layer of metal to the surface of the part to improve wear resistance, reduce friction, or provide an aesthetic finish.

– Types: Tin plating, copper plating.

-

Spraying

– Description: A method where paint or protective coating is sprayed onto the part’s surface. This process is used for both aesthetic and protective purposes, offering a wide range of colors and finishes.

-

Oxidation

– Description: A chemical treatment that forms a protective oxide layer on the surface of metals, such as steel. It improves corrosion resistance and can provide a unique aesthetic finish.

-

Polishing

– Description: A mechanical process that smooths and shines the surface of the part. Polishing removes imperfections and enhances the visual appeal of the metal.

-

Sandblasting

– Description: A process that uses high-speed abrasive particles to clean or roughen the surface. It prepares the surface for further treatments or provides a textured finish.

-

Passivation

– Description: A treatment process that enhances the natural oxide layer on stainless steel to improve corrosion resistance. It involves soaking the part in a solution that removes free iron and other contaminants.

Reviews

There are no reviews yet.