Overview:

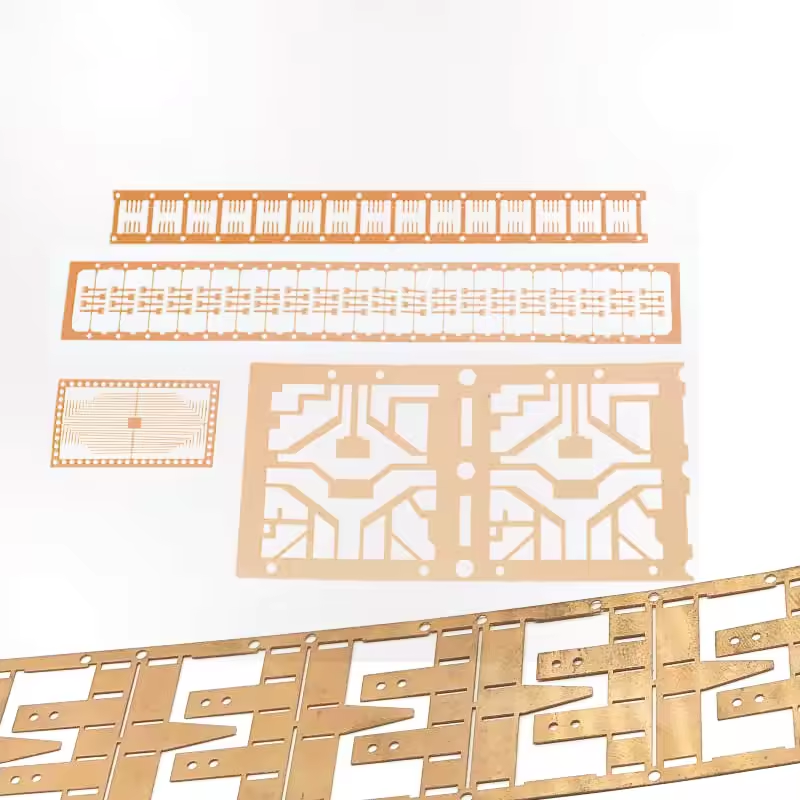

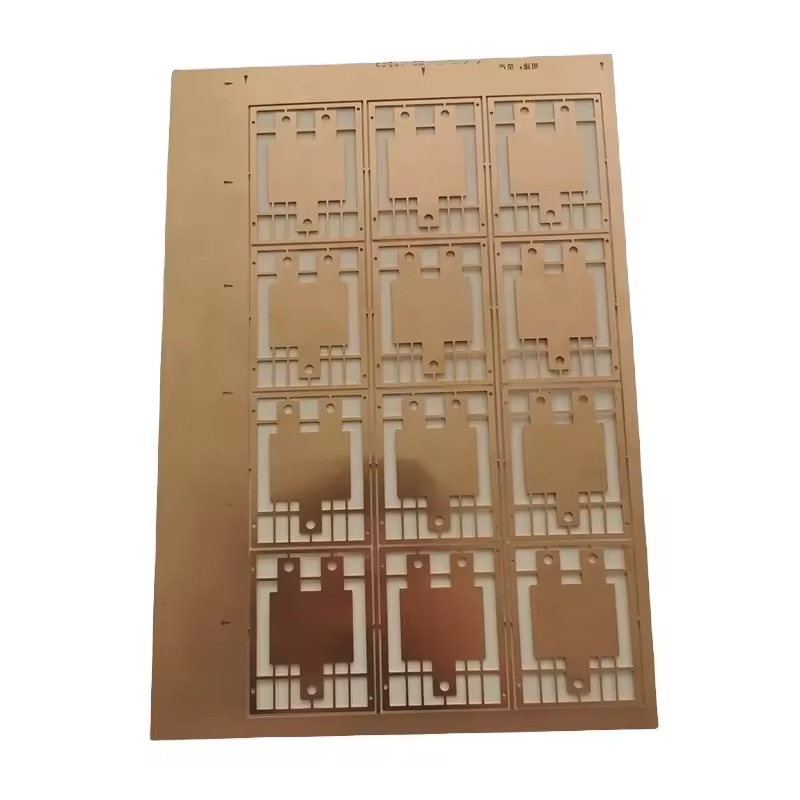

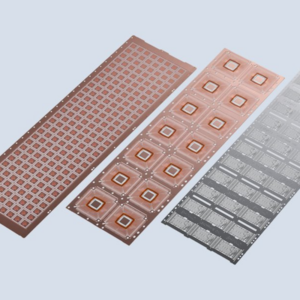

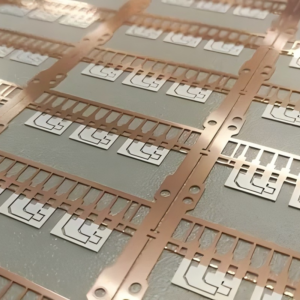

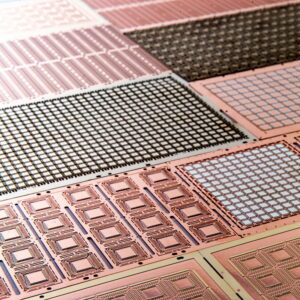

Custom metal sheet stamping LED lead frames are precision-made from high-performance materials such as copper, brass, and enhanced through copper etching for added precision. These components are crucial for optimal electrical conductivity, heat management, and durability in LED lighting systems. Copper etching allows for fine-tuned design features and intricate patterns, improving both functionality and efficiency.

We offer customizable lead frames with various sizes, surface finishes, and plating options to meet your unique specifications. As a trusted supplier and manufacturer, we deliver high-quality, tailored solutions for a wide range of LED applications, ensuring superior performance and reliability.

Characteristics:

- Material: Copper

- Mould: Multistep Progressive Dies

- Industry: LED Application

- Tolerances: ±0.01mm

- Customization: Welcome

- Smallest Open Hole: 0.1mm

- Artwork Formats: AI, CorelDraw, PDF, etc.

- Thickness: 0.03mm – 1.5mm

- Size: Custom

- Transport Package: As required

- Specification: Custom

- Trademark: OEM

- Place of Origin: Xiamen, China

- Production Capacity: 200,000 PCS/Day

Production Process:

- Material Preparation: The process begins with the selection of high-quality copper sheets. These sheets are carefully cleaned and prepped to ensure optimal adhesion during etching and stamping.

- Photoresist Application: A photoresist layer is applied to the surface of the copper sheet. This protective layer is used to define the areas of the copper that will be etched. The material is then exposed to ultraviolet (UV) light through a photographic mask that outlines the desired pattern.

- Etching: After exposure, the photoresist is developed, and the exposed areas of the copper are etched away using a chemical etching solution. This removes unwanted copper, leaving behind the lead frame pattern.

- Stamping: Following etching, the copper sheet is placed in a stamping press where it is formed into the final shape of the LED lead frame. This process uses precision dies to punch, bend, or form the copper into the required configuration.

- Plating: Once the copper lead frame is stamped, it may undergo a plating process such as gold, silver, or tin plating to improve electrical conductivity, corrosion resistance, and surface finish.

- Inspection and Quality Control: Each lead frame is carefully inspected to ensure it meets dimensional tolerances and quality standards. Key checks include visual inspections, dimensional measurements, and functionality tests.

- Cleaning and Final Processing: The final lead frames are cleaned using ultrasonic or other advanced cleaning methods to remove any residual chemicals or contaminants. Additional finishing processes like polishing may be done for a smooth, refined appearance.

- Packaging: The completed LED lead frames are then packaged according to customer specifications, ready for shipment.

Why Choose Us?

Customized OEM Solutions & Comprehensive Assembly Services

With more than 20 years of experience in the manufacturing industry, we specialize in providing tailored OEM solutions and full-spectrum assembly services. Our advanced production capabilities and highly skilled team ensure that every product we deliver is crafted to meet your exact specifications, providing superior performance and reliability.

Extensive Product Range

We offer a broad array of precision-engineered products, including stamped components, CNC-machined parts, springs, shafts, fasteners, and more. As a trusted end-to-end solutions provider, we manage every aspect of your project, from initial design and prototyping to final production and assembly, ensuring streamlined processes and optimal outcomes at each stage.

Industry Certifications & Proven Expertise

As a reputable second-tier supplier, we have successfully passed rigorous factory audits and hold essential industry certifications such as RoHS and HE compliance. These certifications underscore our commitment to meeting international quality standards and ensuring that our products comply with all relevant regulatory requirements.

Unwavering Commitment to Quality

Our adherence to ISO 9001:2015 and IATF 16949 quality management standards highlights our dedication to producing parts of exceptional quality. These certifications guarantee that every product we manufacture is produced with precision, consistency, and durability, maintaining the highest standards of quality control throughout the production process.

Factory Show:

We operate a state-of-the-art manufacturing facility equipped with 25 punch presses (ranging from 25 to 300 tons), precision wire EDM machines, grinding tools, welding equipment, and ultrasonic cleaning systems. Additionally, we offer advanced metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, to enhance product durability, appearance, and functionality. Our automated production lines, c

ombined with stringent quality control and high-quality plating processes, ensure the consistent delivery of precision metal stamping products that meet the highest industry standards.

Reviews

There are no reviews yet.