Description:

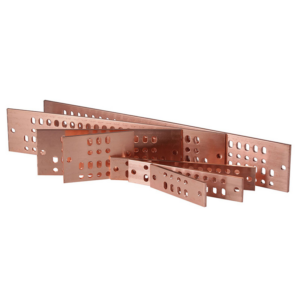

Copper-1100 metal stamped engine sleeves are precision-engineered components made from high-quality copper, offering excellent electrical conductivity, durability, and corrosion resistance. As a leading manufacturer and supplier of custom-engineered solutions, we produce these engine sleeves through a combination of stamping, forming, and machining processes to ensure they meet the most stringent quality standards. The stamping process involves shaping the copper material into the desired sleeve form, while machining further refines the dimensions to achieve precise fitment. We specialize in custom designs, providing tailored solutions to meet the unique specifications of our clients across various applications.

Basic Information:

| Attribute | Details |

| Material | Copper |

| Color | Custom |

| Processing Methods | Deep Drawing |

| Sizes | Customized Sizes |

| MOQ | According to Your Requirement |

| Samples | Custom Samples Can Be Provided |

| Applicable Industries | Electronics Industry |

| Transport Package | Anti-Rust Paper, Carton, Wood Case or Pallet |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

| HS Code | 8483300090 |

| Production Capacity | 100,000 Pieces/Month |

Surface Finishing Options:

- Electroplating – A process where a thin layer of metal is applied to the copper surface to enhance corrosion resistance and improve wear resistance.

- Polishing – A finishing technique that results in a smooth, reflective surface, often used for aesthetic purposes and to reduce friction.

- Passivation – This process involves treating the copper surface with an acid solution to remove contaminants, which enhances corrosion resistance by creating a protective oxide layer.

- Anodizing – While typically associated with aluminum, anodizing can also be applied to copper for increased surface hardness, wear resistance, and a durable protective layer.

Advantages of Bushings:

- Reduced weight

- Cost-effective

- Increased load-bearing capacity

- Enhanced resistance to shock loads and vibrations

- Greater tolerance to shaft misalignment

Our Factory:

We operate a comprehensive range of facilities and equipment to guarantee top-tier production quality. Our plant is equipped with 25 punch presses, ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding tools, welding and polishing equipment, and ultrasonic cleaning systems. In addition to these capabilities, we offer various metal plating processes, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing, to enhance the durability, appearance, and functionality of our metal stamping products. Our advanced plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards. This combination of automated production lines, cutting-edge machinery, strict quality control, and high-quality plating processes allows us to consistently deliver metal stamping products of the highest standard.

Reviews

There are no reviews yet.