Description:

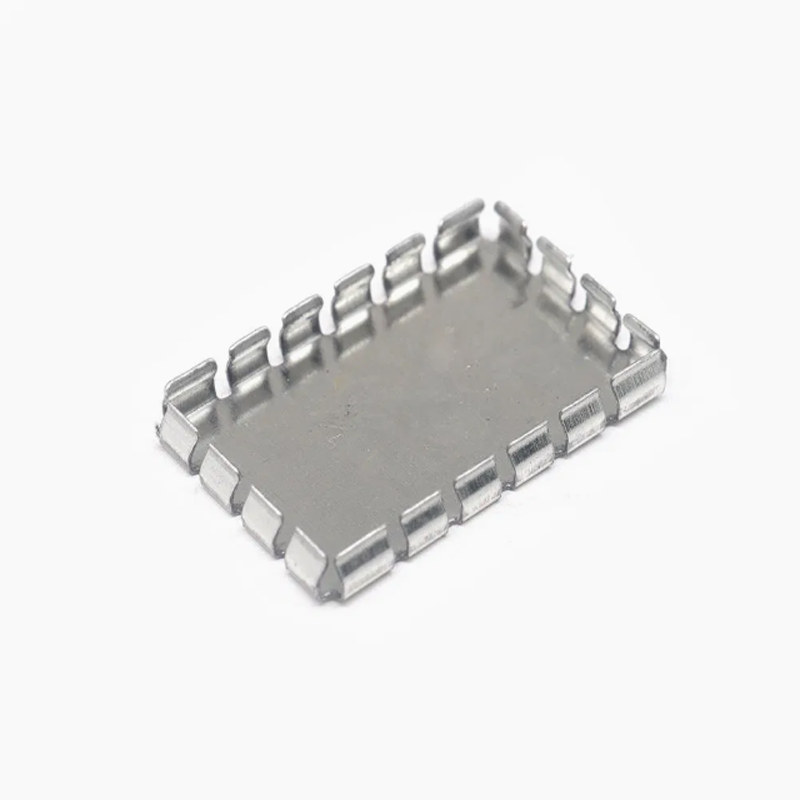

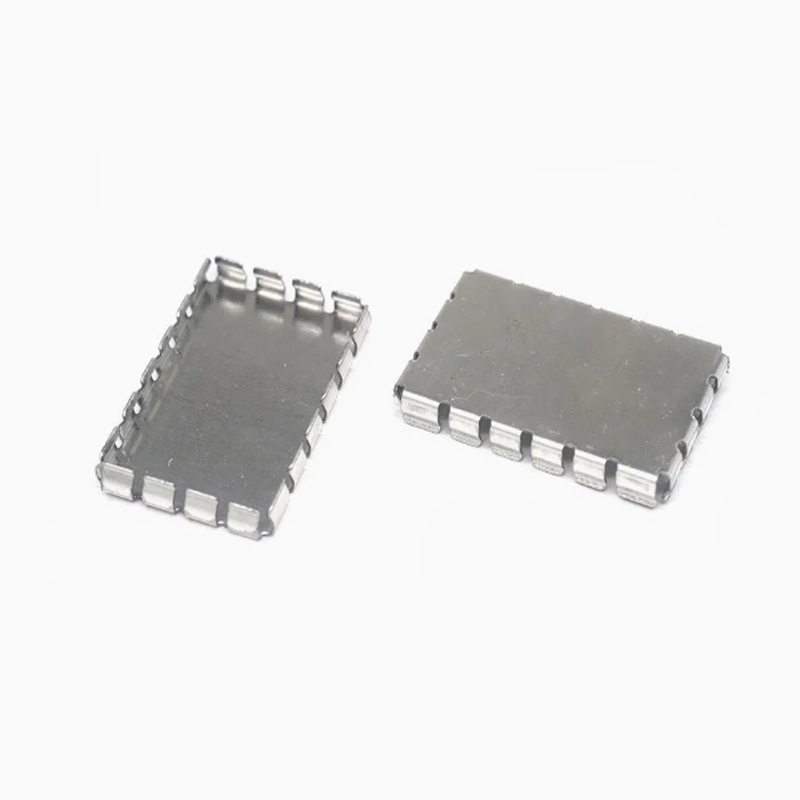

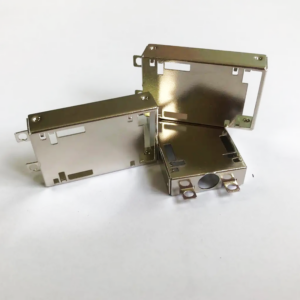

As a trusted manufacturer and supplier of OEM metal shield components, including enclosures and housings, we deliver exceptional protection against electromagnetic interference (EMI) to ensure the reliable operation of sensitive electronic systems. Engineered from conductive or magnetic materials, our precision-stamped metal parts are designed to meet the rigorous demands of applications such as automotive systems, where minimizing interference is crucial for performance and safety. Rely on our expertise to provide durable, high-quality EMI shielding solutions tailored to your specific requirements.

Basic Information:

| Category | Details |

| Mould | In-House Die Making |

| Surface Processing | Electroplating |

| Process | Fine Blanking, Multi-Position, Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customization | Warmly Welcomed |

| Material Available | Copper, Stainless Steel, Carbon Steel, Aluminum, etc. |

| Usage | Automotive, Agriculture, Furniture, Machinery |

| Stamping Die | In-House Die Making |

| Samples | Free Available |

| Service | OEM |

| File Format | CAD, Solidworks, PDF, etc. |

| Transport Package | As Per Your Requests |

| Trademark | OEM |

| Origin | Xiamen, China |

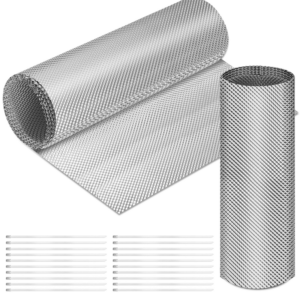

Surface Finishing Options:

-

Electroplating

This technique involves applying a metallic coating, such as zinc, nickel, or gold, to the surface of the shield. Electroplating enhances corrosion resistance, improves durability, and boosts conductivity, making it ideal for high-performance shielding.

-

Powder Coating

A dry application process that creates a smooth, durable, and protective layer. Powder coating effectively shields the metal surface from harsh environmental factors and mechanical wear, ensuring long-lasting performance.

-

Anodizing

Primarily used for aluminum shields, anodizing forms a robust, corrosion-resistant layer while offering enhanced surface hardness. This process also allows for color customization to meet specific design or branding needs.

-

Laser Marking/Engraving

Utilizing laser technology, this process precisely imprints logos, serial numbers, or other identifiers onto the shield’s surface. The result is a clean, permanent marking that does not compromise the shield’s structural integrity.

These advanced surface finishing techniques ensure the metal shields deliver superior electromagnetic interference (EMI) protection while meeting the durability demands of automotive applications.

Production Process:

-

Material Selection

The process begins with selecting optimal materials such as copper, stainless steel, or aluminum, chosen for their exceptional electromagnetic shielding properties and long-term durability.

-

Die Design and Manufacturing

Custom dies are meticulously designed and fabricated in-house to achieve precision stamping, ensuring the shields adhere to exact dimensional and geometric requirements.

-

Stamping

Using advanced stamping equipment, the chosen material is formed into highly precise components that integrate seamlessly into automotive assemblies, meeting the industry’s stringent performance standards.

-

Surface Treatment

Additional processes, such as electroplating or specialized coatings, are applied to enhance corrosion resistance and maximize the shielding performance of each component.

-

Quality Assurance

Every part undergoes rigorous quality inspections, ensuring compliance with strict tolerances—down to 0.02mm—and functional benchmarks for superior reliability.

-

Assembly and Packaging

Completed metal shields are carefully assembled and packaged to safeguard quality during transit and ensure readiness for integration into automotive systems.

-

OEM Customization

Throughout the production cycle, we offer comprehensive OEM services, including customized designs, specifications, and branding to meet the unique needs of our clients.

Our Factory:

Topmetalstamping operates a state-of-the-art production facility equipped with 25 punch presses (25–300 tons), precision wire EDM machines, grinding tools, welding, polishing, and ultrasonic cleaning systems. These advanced resources ensure efficient production of high-precision components with exceptional accuracy.

We also provide premium metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our advanced plating facilities ensure uniform finishes, superior corrosion resistance, and compliance with industry standards.

With automated systems, advanced machinery, and strict quality control, we deliver durable, reliable, and high-quality metal stamping products tailored to meet our clients’ exact requirements.

Reviews

There are no reviews yet.