In today’s fast-paced and competitive market, maintaining exceptional quality standards is essential for businesses aiming to stay ahead. Meeting customer expectations is no longer enough; companies must also comply with rigorous industry regulations. At Topmetalstamping, we are proud to adhere to the ISO 9001:2015 certification, a globally recognized standard that reflects our dedication to quality across all aspects of our operations. This certification is more than just a seal; it represents our commitment to consistent quality, customer satisfaction, and continuous improvement.

What is ISO 9001:2015 Certification?

ISO 9001:2015 is an internationally recognized quality management system (QMS) standard designed to help organizations deliver consistent products and services that meet customer requirements and regulatory standards. For Topmetalstamping, this certification ensures that our QMS is not only well-documented but also actively evolving to guarantee that we continually improve the quality of our products and services. It is a dynamic system that promotes ongoing enhancement, ensuring our customers receive the highest level of service and reliability.

The Importance of ISO 9001:2015 for Your Business

ISO 9001:2015 certification is not just a formality; it plays a key role in driving business growth and customer satisfaction. By maintaining ISO 9001:2015, Topmetalstamping ensures that every product and service we provide aligns with the highest customer and regulatory expectations. This standard is especially crucial for industries like automotive, manufacturing, healthcare, and construction, where precision, safety, and quality assurance are paramount.

Some of the key benefits of ISO 9001:2015 certification include:

– Enhanced Customer Satisfaction: Our robust QMS helps us consistently meet or exceed customer expectations, leading to higher satisfaction and improved customer loyalty.

– Increased Operational Efficiency: By adhering to ISO 9001:2015 standards, we streamline operations, minimize waste, and reduce costs, which directly benefits our clients.

– Market Competitiveness: ISO 9001:2015 certification demonstrates our ability to produce reliable, high-quality products that meet international standards, offering us a competitive edge in the marketplace.

Industries That Benefit from ISO 9001:2015 Certification

ISO 9001:2015 certification is valuable across various industries, ensuring that products meet rigorous quality standards. These industries include:

– Manufacturing: From metal stamping to aerospace, automotive, and industrial applications, our QMS ensures that products are precise and compliant with all regulatory requirements.

– Healthcare: In the healthcare sector, where product safety and regulatory compliance are critical, our QMS guarantees that our metal stamping services meet the specific needs of this highly regulated industry.

– Automotive and Defense: With safety and precision at the forefront, ISO certification assures that every part we produce adheres to the strictest safety standards, reducing risk and enhancing performance.

– Construction & Engineering: Parts for these industries must meet specific durability and safety requirements. ISO 9001:2015 certification ensures that our products are reliable and perform as expected in critical applications.

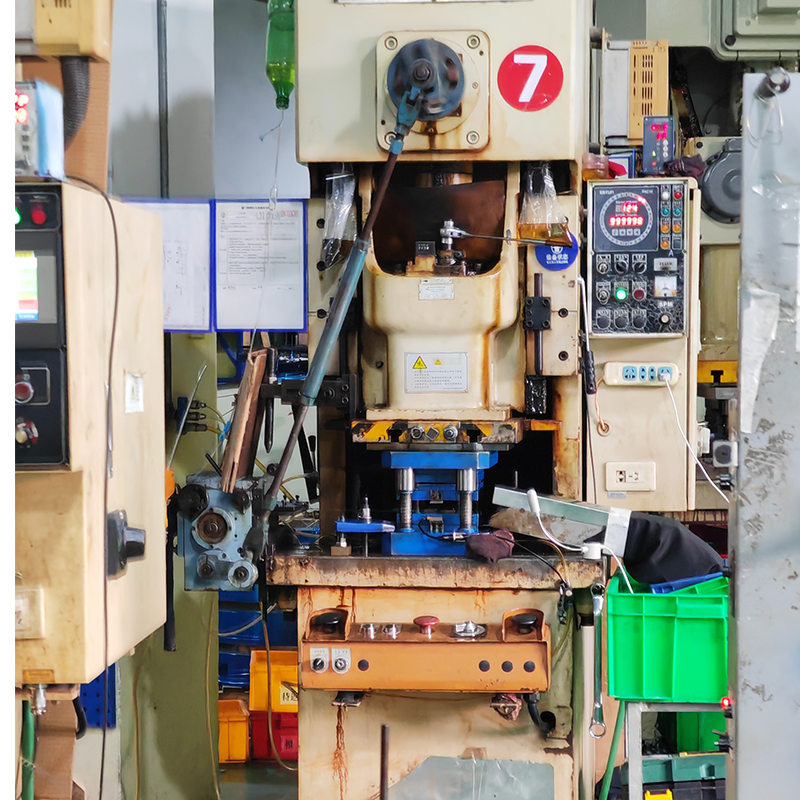

Our Quality Process at Topmetalstamping

At Topmetalstamping, quality is integrated into every step of our process. We follow a proactive, risk-based approach to ensure that every product we manufacture is consistently precise and reliable. Here’s a closer look at how we ensure the highest standards of quality:

- Digital Inspection and Photography: Our advanced digital inspection tools capture accurate measurements and identify potential defects during production, ensuring precision at every stage.

- Optical Comparators: These devices compare parts to CAD drawings, ensuring that all components meet dimensional accuracy and specifications.

- Statistical Process Control (SPC): We continuously monitor our processes using SPC tools to identify any variations early and make adjustments to maintain product consistency.

- Tensile Strength Testing (ASTM D412): This test measures material strength, ensuring that components can withstand the stress they’ll face in real-world applications.

- Hardness Testing: To meet specific requirements for material hardness, we conduct detailed tests, ensuring that the product’s properties align with its intended use.

- Surface Roughness Measurement: We measure and control the surface finish of parts, ensuring that they meet industry-specific quality and functional requirements.

- In-House Calibration Systems: Our calibration system, traceable to NIST standards, guarantees the accuracy of all measuring instruments, ensuring reliable test results.

- First Article Inspections (FAI): We conduct thorough inspections of the first batch of parts to verify that they meet design specifications before full-scale production begins.

- Product Flow Monitoring: We track every product throughout its lifecycle, ensuring traceability from raw materials to the final part, ensuring complete transparency and accountability.

Access to Our Quality Department

Transparency is at the heart of our approach at Topmetalstamping. Our customers have direct access to our dedicated Quality Department, where they can request detailed reports, inspection data, and insights into our processes. This open communication helps us collaborate closely with our clients and ensures that we meet their unique needs at every stage of production.

Why Choose Topmetalstamping?

Partnering with Topmetalstamping means choosing a company that is unwavering in its commitment to maintaining the highest quality standards. Here’s why our clients trust us:

– Precision: We consistently deliver highly accurate products, ensuring that even the tightest tolerances are met with precision. This is essential for industries like automotive, aerospace, and medical.

– Customization: We specialize in creating custom metal stampings that meet your exact specifications, offering tailored solutions to fit your unique needs.

– Efficiency: Our ISO 9001:2015-certified QMS helps streamline our operations, reducing turnaround times and lowering costs, all while maintaining high product quality.

– Reliability: Our strict quality control ensures that all products are durable, functional, and long-lasting, providing you with reliable parts that require minimal rework.

Get in Touch with Us Today

At Topmetalstamping, our ISO 9001:2015 certification reflects our commitment to delivering exceptional, reliable products. Whether you require precision metal stamping for automotive, medical, or construction applications, we’re here to meet your needs.

Contact us today to request a quote or learn more about how our precision-engineered metal stamping services can support your business. With our certified processes and dedication to quality, Topmetalstamping is your trusted partner for all your metal stamping requirements.