In the competitive landscape of modern manufacturing, companies are constantly seeking ways to optimize their production processes. One such strategy is leveraging the advantages of custom metal stamping services. This innovative approach provides businesses with the opportunity to streamline operations, reduce costs, and enhance product quality. In this blog, we’ll delve into the numerous benefits of custom metal stamping, explore its precise manufacturing process, and highlight why choosing the right service provider, like Topmetalstamping, can unlock new levels of success for your business.

What is Custom Metal Stamping?

Custom metal stamping is a manufacturing process that involves shaping metal sheets or strips into intricate components using specialized dies and presses. The process begins with designing and creating a custom die, which acts as the tool that will cut, shape, and form the metal into the desired part. Once the die is completed, it is installed in a press, where metal sheets are fed through to undergo precise stamping, cutting, and shaping according to the die’s specifications.

Thanks to the use of advanced techniques such as CNC machining and laser cutting, custom metal stamping offers unparalleled precision. This allows manufacturers to create complex and detailed parts with minimal tolerance variations. The efficiency of the stamping process also ensures a high level of repeatability, making it ideal for large production runs and mass manufacturing.

Key Benefits of Custom Metal Stamping

Custom metal stamping offers a wide array of advantages that can significantly improve manufacturing operations, including cost savings, high precision, design flexibility, and strength. Here are some of the most notable benefits:

1. Cost-Effectiveness

One of the most significant advantages of custom metal stamping is its ability to produce large quantities of parts quickly and at a lower cost per unit. By utilizing custom dies, manufacturers can optimize their production process, resulting in reduced labor costs and shorter lead times. Additionally, the process is highly efficient, ensuring that businesses can take full advantage of economies of scale—which translates into substantial savings as production volumes increase.

Compared to traditional manufacturing methods like machining or casting, custom metal stamping offers a far more cost-effective solution. The use of specialized dies that are reusable also eliminates the need for expensive tooling for each part, further reducing production expenses.

2. Precision and High-Quality Output

Precision is paramount in industries that demand exact specifications, such as automotive, aerospace, electronics, and medical sectors. Custom metal stamping excels in providing parts with tight tolerances and exceptional consistency. Advanced machinery, like CNC machines, ensures that each stamped part meets the required specifications with high accuracy.

The use of laser cutting and die technology further contributes to the precision of stamped parts, delivering clean edges and intricate designs. This level of precision is crucial for maintaining product performance, safety, and compliance with industry standards.

3. Design Flexibility and Customization

Another major benefit of custom metal stamping is its flexibility in design and customization. Manufacturers can work with custom dies to create parts that meet unique design specifications. The ability to emboss, deboss, texture, or add other surface features to the metal allows businesses to tailor their products to meet specific customer needs and market demands.

Whether it’s a change in size, shape, or material, custom metal stamping can easily accommodate modifications, ensuring that manufacturers can quickly adapt to new trends or evolving customer requirements. Moreover, this design flexibility is especially advantageous for creating intricate, high-performance parts with both aesthetic and functional enhancements.

4. Durability and Strength

Custom metal stamped parts are renowned for their durability and strength. Due to the precision manufacturing process, each part is crafted with high-quality materials to ensure robustness and long-lasting performance. Whether in high-pressure environments, automotive applications, or industrial machinery, stamped metal parts are designed to withstand demanding conditions.

Furthermore, additional post-processing treatments, such as heat treatment or surface coatings, can further improve the durability of these components. These enhancements offer protection against corrosion, wear, and environmental factors, ensuring that the parts perform reliably throughout their lifecycle.

5. Material Versatility

Custom metal stamping services offer manufacturers the ability to choose from a wide range of materials, each suited to specific applications. Some of the most commonly used metals include:

- Stainless Steel– Known for its excellent corrosion resistance and high strength, stainless steel is widely used in industries like automotive, food processing, and medical equipment.

- Aluminum– Lightweight and highly corrosion-resistant, aluminum is used in aerospace, electronics, and consumer goods industries.

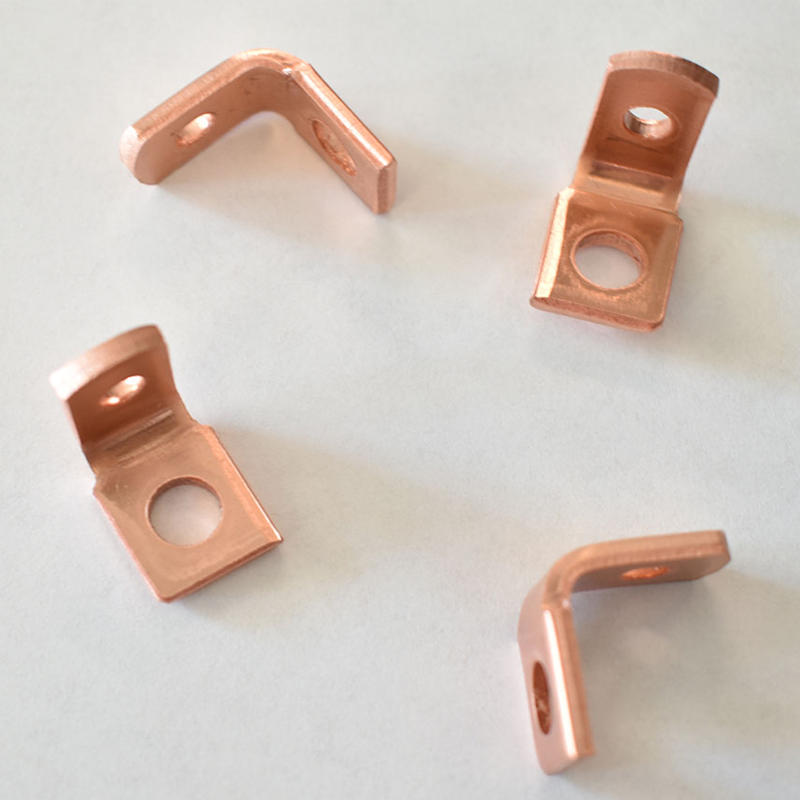

- Copper– Offering superior electrical and thermal conductivity, copper is essential in electrical applications.

- Brass– A versatile material with good corrosion resistance, commonly used in plumbing, decorative items, and musical instruments.

Additionally, custom metal stamping allows manufacturers to work with specialized alloys and metals, ensuring the best material selection for each part based on strength, conductivity, and corrosion resistance.

Applications of Custom Metal Stamping

The versatility of custom metal stamping services extends across various industries, making it an ideal solution for producing high-precision parts used in a multitude of applications. Some key industries that rely heavily on custom metal stamping include:

- Automotive Industry– Custom metal stamping is integral to the production of components like body panels, brackets, and engine parts that demand high strength and precision.

- Aerospace Industry– Critical components such as structural parts, fasteners, and connectors are often manufactured through metal stamping, ensuring reliability and safety.

- Electronics Industry– Custom stamped metal parts, including connectors and terminals, are crucial for the performance of electronic devices, offering excellent conductivity and durability.

- Medical Devices– Surgical instruments, implants, and diagnostic tools require high precision and biocompatibility, making custom metal stamping essential for the medical field.

- Consumer Goods– From kitchen appliances to decorative hardware, custom metal stamping adds value through design flexibility and strength.

Choosing the Right Custom Metal Stamping Provider

While the benefits of custom metal stamping are clear, choosing the right service provider is critical for ensuring that your manufacturing needs are met with quality and efficiency. At Topmetalstamping, we pride ourselves on delivering top-tier metal stamping solutions, tailored to your exact specifications. When selecting a provider, here are some factors to consider:

- Experience and Expertise– Look for a company with years of experience in the industry, capable of handling complex projects and delivering high-quality results.

- Quality Control– Ensure that the provider adheres to stringent quality standards, such as ISO 9001 certification, to guarantee consistent results.

- Advanced Technology– Check if the company uses state-of-the-art machinery, like CNC machines and laser cutting equipment, for superior precision.

- Material Options– A good provider should offer a wide range of materials to ensure the best match for your part’s performance requirements.

- Customer Support– A reliable provider will offer engineering support to help optimize designs and ensure the best possible outcome.

Conclusion

Incorporating custom metal stamping into your manufacturing process offers significant advantages, including cost-effectiveness, precision, flexibility, and durability. By partnering with a trusted provider like Topmetalstamping, you can access a wide range of high-quality materials, advanced technologies, and expert support to take your production capabilities to the next level.

Are you ready to improve your manufacturing efficiency and unlock the full potential of custom metal stamping? Contact us today at Topmetalstamping, and let’s discuss how our services can help your business thrive in today’s competitive market. We’re here to help you make precision and efficiency the cornerstone of your success.