In the fast-paced and ever-evolving world of manufacturing, custom metal stamping has become an essential process for producing precision parts tailored to the unique demands of various industries. Whether you’re in the automotive, medical, electronics, or industrial sectors, custom metal stamping offers an efficient, cost-effective solution that meets specific production needs. As businesses continually strive to improve their manufacturing processes, selecting the right production method is vital for ensuring efficiency, quality, and cost-effectiveness.

At Topmetalstamping, we specialize in offering high-quality custom metal stamping services designed to meet the precise needs of each client. Whether you require micro-components for delicate medical devices or large, durable parts for industrial machinery, our experienced team, cutting-edge technology, and commitment to excellence can help bring your designs to life. In this blog post, we will explore the various advantages of custom metal stamping and highlight the numerous applications that make it an ideal choice for a wide range of industries. If you’re considering custom metal stamping for your manufacturing needs, keep reading to discover how this process can enhance your production efficiency and quality.

What is Custom Metal Stamping?

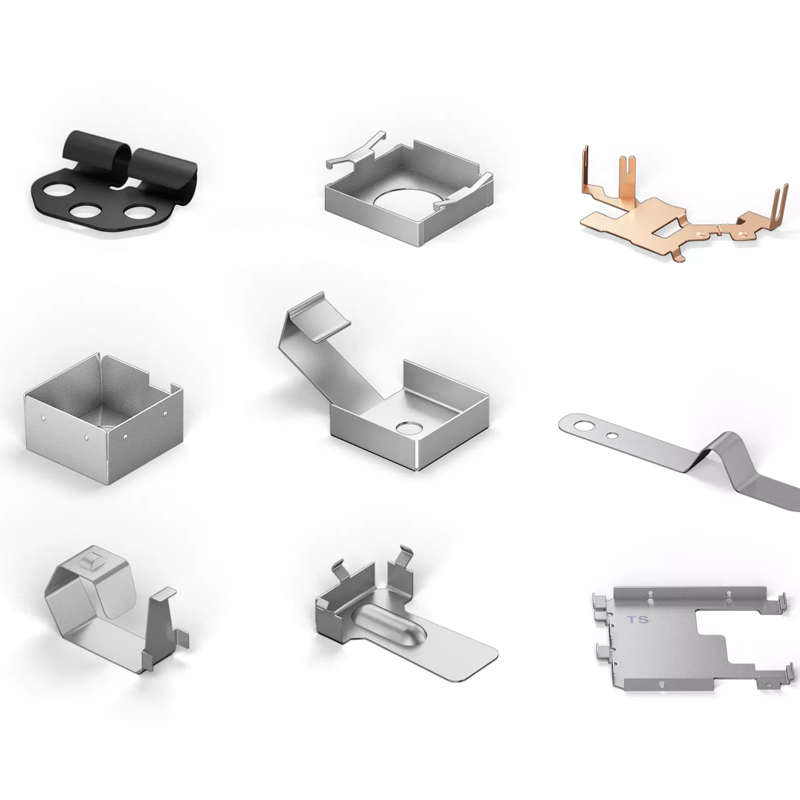

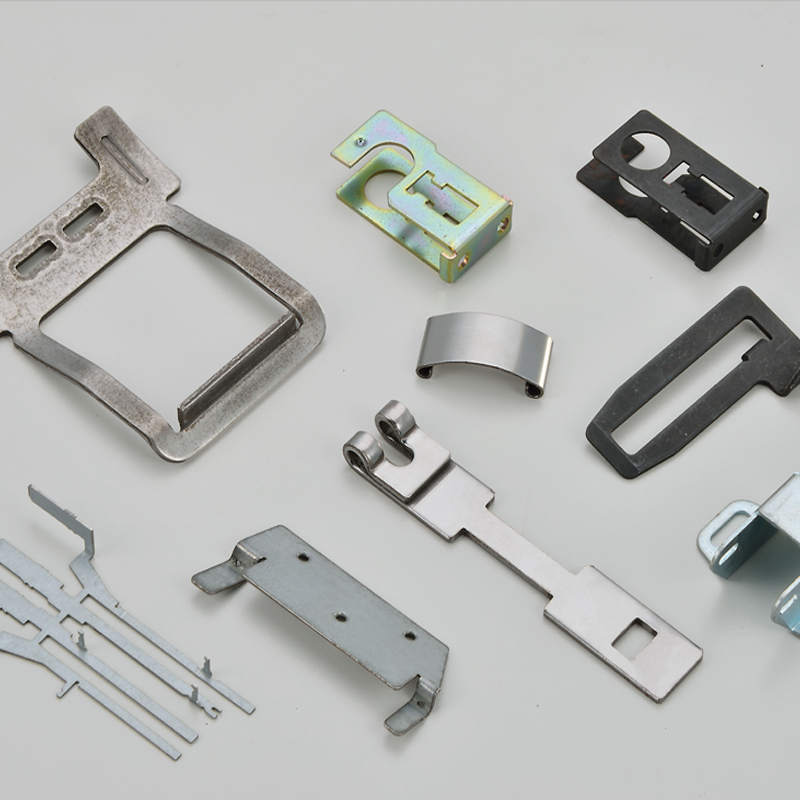

Custom metal stamping is a manufacturing technique used to create precise metal parts by cutting and shaping metal sheets through the use of specialized dies and stamping presses. This highly versatile method enables manufacturers to produce parts with intricate geometries and complex designs, ensuring that components meet functional, dimensional, and aesthetic requirements. From micro-components used in electronics to large-scale automotive or industrial parts, custom metal stamping is a go-to solution for industries that demand precision, reliability, and high-performance components.

The process begins with the creation of a custom die, designed specifically to cut, form, and shape the metal as it passes through the stamping press. Stamping presses can produce parts in various shapes, sizes, and materials, depending on the design specifications. The precision tooling used in this process ensures that the final parts adhere to strict tolerances, making custom metal stamping ideal for industries where precision and consistency are critical.

Key Benefits of Custom Metal Stamping

Custom metal stamping offers a host of significant advantages, making it a preferred manufacturing method for producing specialized metal components across a wide range of industries. Below are some of the key benefits:

Cost-Effectiveness

One of the primary reasons companies choose custom metal stamping is its cost-effectiveness, especially for high-volume production runs. Once the custom die is created, the stamping process can be automated, allowing for the fast, efficient production of large quantities of parts. This reduces labor costs and increases production speed. Additionally, custom metal stamping minimizes material waste, ensuring that resources are used efficiently, which lowers per-unit costs and helps businesses achieve better margins. Whether you require hundreds or thousands of parts, custom metal stamping provides an affordable solution for your business.

Precision and Accuracy

Precision is paramount when manufacturing metal parts, especially in industries such as medical devices, aerospace, and electronics, where functionality and safety depend on strict tolerances. Custom metal stamping provides exceptional accuracy, ensuring that every part meets the specified dimensions and performs reliably in its intended application. At Topmetalstamping, we emphasize precision in every phase of production to ensure that each part adheres to your exact specifications, resulting in consistent, high-quality components that are fit for even the most demanding applications.

Design Flexibility

Off-the-shelf metal components often do not meet the specific design requirements of complex or specialized applications. Custom metal stamping allows you to create parts that are tailored to your unique needs, offering the flexibility to produce components with intricate shapes, sizes, and material properties. Whether you are designing a highly specialized component for medical devices or need custom parts for industrial machinery, custom metal stamping provides the versatility to achieve complex designs while maintaining optimal performance and quality.

Durability and Strength

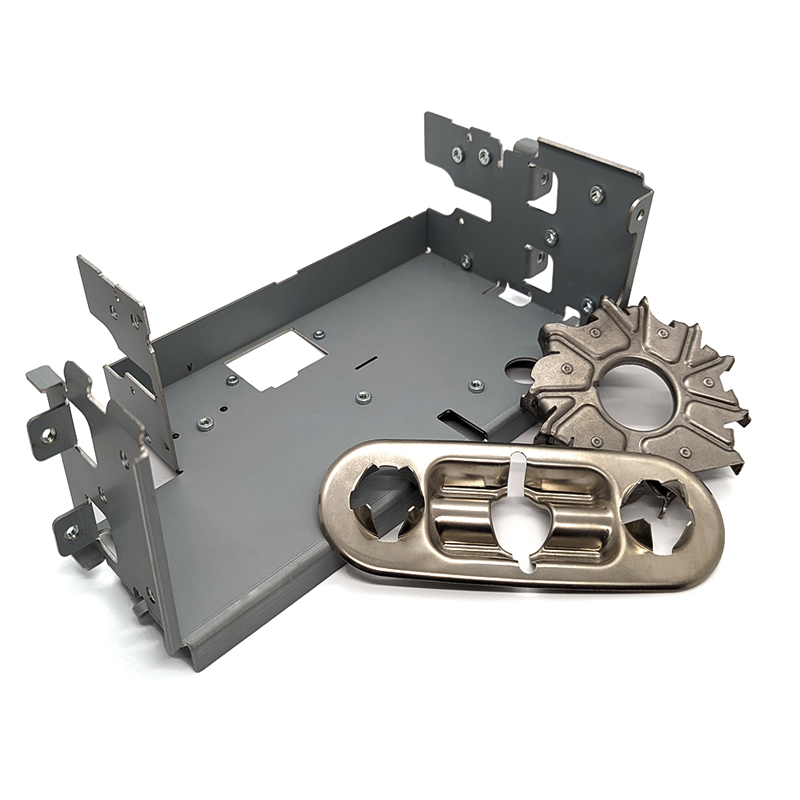

The durability and strength of stamped parts make them ideal for use in demanding environments. Custom metal stamping can produce parts from various metals, each offering specific properties to enhance performance in particular applications. For instance, materials like stainless steel, aluminum, and brass are often chosen for their strength, corrosion resistance, and longevity. The result is a final product that is durable and able to withstand harsh conditions, reducing the need for frequent repairs or replacements.

High Efficiency and Scalability

Custom metal stamping is particularly efficient in high-volume production settings. Once the custom die is designed, the stamping process can be automated, allowing for fast production cycles and enabling manufacturers to scale up production as needed. This is particularly beneficial for industries such as automotive and consumer electronics, where large quantities of parts are required to meet market demand. With custom metal stamping, businesses can ensure quick turnaround times without compromising on quality or precision.

Applications of Custom Metal Stamping

The versatility of custom metal stamping makes it suitable for a broad range of industries and applications. Some of the key sectors that rely on custom metal stamping include:

– Automotive: Custom metal stamping is widely used to produce parts for vehicles, including brackets, clips, housings, and larger components used in vehicle assemblies. The ability to create durable, high-performance parts is essential for ensuring the safety and efficiency of automotive components.

– Electronics: In the electronics industry, custom metal stamping plays a vital role in manufacturing components such as connectors, terminals, shields, and heat sinks. Precision stamping ensures these components meet stringent quality standards and function optimally in electronic devices.

– Medical Devices: Custom metal stamping is essential for producing parts used in medical devices, surgical instruments, and implantable components. The process ensures that parts meet the exacting standards of precision, safety, and regulatory compliance required in the medical field.

– Oil and Gas: Custom metal stamping is used to manufacture parts for the oil and gas industry, including seals, connectors, and pipe fittings. These components must be durable and able to withstand extreme temperatures, pressure, and exposure to harsh chemicals, making custom metal stamping the ideal solution for this demanding sector.

– Appliances: From refrigerators and ovens to HVAC systems and outdoor grills, custom metal stamping is used to create components for household and commercial appliances. Whether producing large or small parts, this process ensures that appliances are reliable and functional.

Why Choose Topmetalstamping for Your Custom Metal Stamping Needs?

At Topmetalstamping, we pride ourselves on our ability to deliver superior custom metal stamping parts tailored to your specific requirements. With a focus on precision, cost-efficiency, and innovation, we work closely with clients to develop solutions that meet the highest industry standards. Whether you require small, intricate components or large, robust parts, we have the technology and expertise to help you achieve your manufacturing goals.

Ready to enhance your production process with custom metal stamping? Contact us today to discuss how we can help streamline your manufacturing operations. Request a quote or reach out to our team to explore the best solutions for your specific needs. By choosing Topmetalstamping, you’re partnering with a company dedicated to delivering high-quality, reliable parts that meet your exact specifications. Don’t settle for less—trust us to provide the precision and performance your business demands.

Topmetalstamping is your trusted partner for custom metal stamping, ensuring that every part you receive meets the highest standards of quality, durability, and performance. Let’s work together to elevate your manufacturing process.