In today’s fast-paced and highly competitive manufacturing environment, companies are continuously searching for ways to optimize production processes, reduce costs, and maintain high standards of quality. One of the most efficient methods to achieve these goals, particularly in low-volume production, is small batch CNC machining. At Topmetalstamping, we specialize in providing high-quality, precision-driven small batch CNC machining services designed to meet the unique needs of each client. Whether you are developing a prototype, creating a custom component, or producing a small series of parts, small batch CNC machining offers significant advantages that can provide your business with the flexibility, efficiency, and precision it needs to stay ahead of the competition.

What is Small Batch CNC Machining?

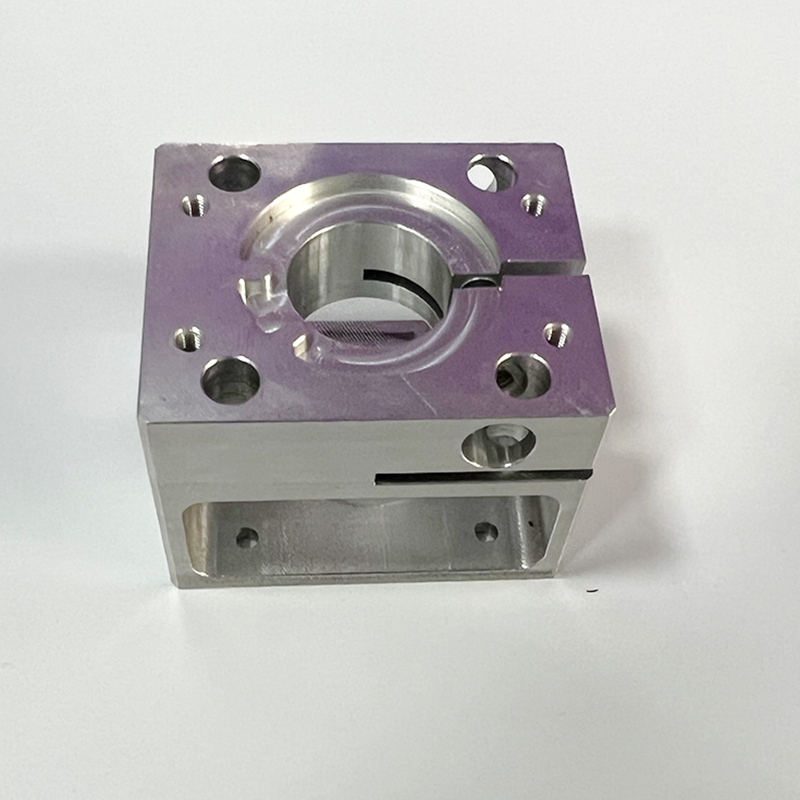

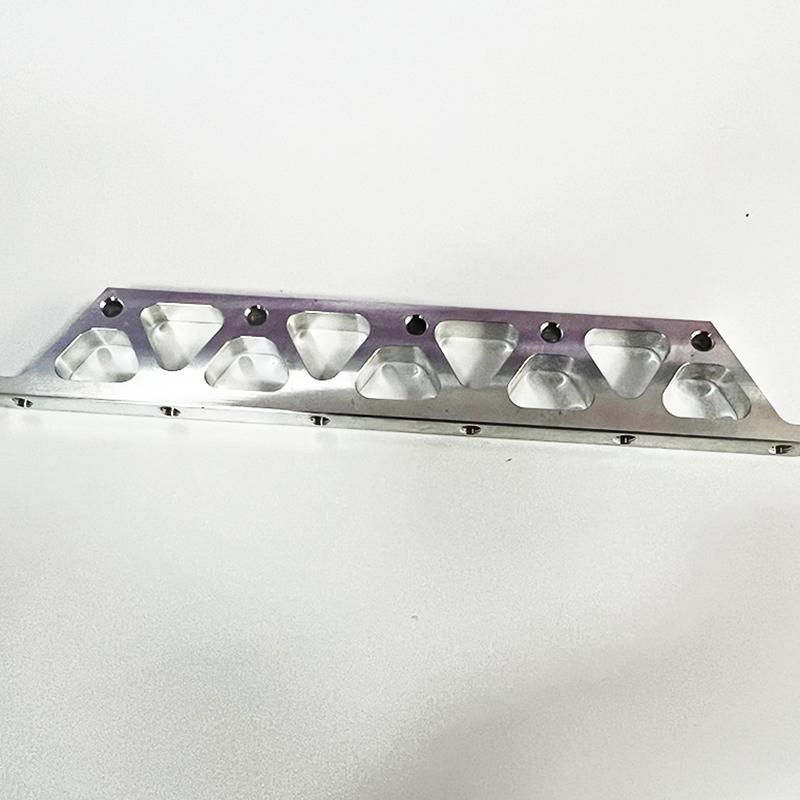

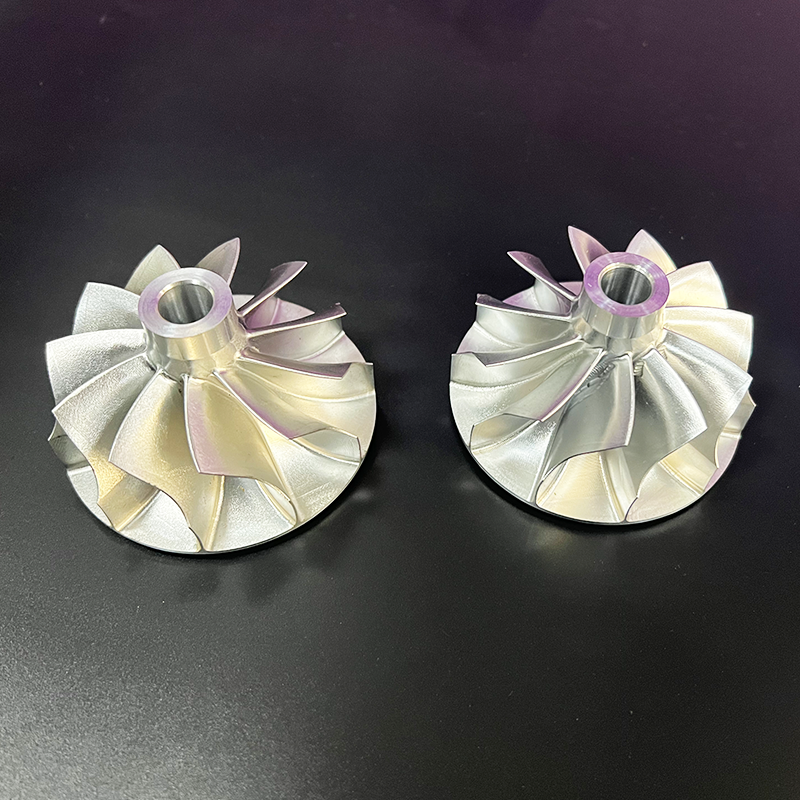

Small batch CNC machining is a manufacturing process where a limited number of components, typically ranging from one to 100 units, are produced using computer numerical control (CNC) machines. This method is particularly beneficial for industries that require high precision, customization, and the ability to prototype or test designs without the need for large-scale production setups. CNC machines utilize advanced computer-controlled tools to create parts with intricate features, complex shapes, and high accuracy, ensuring that even small quantities of parts can be produced with exceptional quality.

By employing CNC technology, manufacturers can achieve consistency in quality and dimensional accuracy, even in small production runs. The flexibility inherent in CNC machining allows for quick modifications to designs, which makes it easy for companies to respond to customer feedback and shifting market demands. At Topmetalstamping, we offer a broad range of small batch CNC machining services, ensuring that every component we produce meets the highest industry standards for quality, durability, and performance.

Key Benefits of Small Batch CNC Machining

Small batch CNC machining offers several compelling advantages over traditional manufacturing methods, particularly for businesses that need to produce limited quantities of parts. Below are some of the key benefits:

-

Cost Efficiency

One of the most significant advantages of small batch CNC machining is its cost efficiency. Compared to large-scale manufacturing processes, which often involve substantial investments in molds, tooling, and setup, small batch production significantly reduces financial barriers. By minimizing setup costs, businesses can produce high-quality parts at lower costs while maintaining precision and reliability.

-

Design Flexibility

CNC machining offers unmatched flexibility in design. Unlike traditional manufacturing methods that require expensive tooling and molds, CNC machines can quickly accommodate design changes without the need for additional tooling. This makes it possible for businesses to refine their products during the production process, which is especially valuable when responding to customer feedback or adapting to market shifts. This design agility ensures that companies do not incur additional costs when modifying designs for better functionality or performance.

-

Fast Turnaround Time

In today’s competitive market, speed is crucial. Small batch CNC machining allows for faster prototyping and production times compared to conventional methods. This enables businesses to meet tight deadlines, accelerate time-to-market, and stay ahead of industry trends. Whether you are testing a new product or fulfilling an urgent order, CNC machining ensures that parts are produced quickly without compromising quality.

-

High Precision and Consistency

CNC machines are known for their accuracy and repeatability. Small batch CNC machining ensures that even the most complex and detailed parts are manufactured to precise specifications. This level of precision is critical for industries such as aerospace, medical devices, and automotive manufacturing, where high tolerances are essential. CNC technology guarantees consistent results, providing you with the reliability and performance you need.

-

Prototyping and Testing

Small batch CNC machining is ideal for companies that need to test prototypes or validate new designs before moving to mass production. This process allows businesses to evaluate the functionality, fit, and performance of parts in real-world applications without committing to large-scale manufacturing. By identifying potential issues early in the production process, companies can reduce the risk of costly mistakes and make informed decisions about whether to proceed with full-scale production.

-

Customization

Small batch CNC machining offers unparalleled customization options. Whether you need parts for specialized machinery, custom tools, or unique consumer products, CNC machining allows for the production of tailor-made components that meet precise design and functional requirements. This level of customization is often difficult to achieve with larger production runs, making small batch CNC machining an invaluable tool for businesses with specific or complex needs.

CNC Machining Techniques in Small Batch Production

Small batch CNC machining encompasses a wide variety of techniques, each of which is suited to different types of parts and production requirements. Some of the most commonly used CNC processes include:

– CNC Turning

CNC turning involves rotating the workpiece while a cutting tool moves along linear paths to shape the material. This method is ideal for creating cylindrical parts such as shafts, bushings, and gears. CNC turning is frequently used in small batch production for components with rotational symmetry.

– CNC Milling

CNC milling uses rotary cutters to remove material from the workpiece. This versatile technique is used to create complex features such as holes, slots, and contours. CNC milling is commonly used for producing custom parts with intricate three-dimensional shapes.

– CNC Drilling

CNC drilling is used to create precise holes in a workpiece by rotating a drill bit. Often integrated with milling or turning operations, CNC drilling allows for the production of parts that require accurate holes for fasteners or other mechanical features.

– Electrical Discharge Machining (EDM)

Sinker EDM and wire EDM are used to produce highly detailed and intricate parts, often from hard metals. EDM is ideal for parts with complex geometries that require tight tolerances and fine features, such as molds and dies.

– Surface Grinding

Surface grinding is used to achieve a smooth, accurate finish on the surface of a workpiece, ensuring dimensional precision and surface uniformity. It is frequently used to create high-precision metal parts in industries such as aerospace and tooling.

Materials Commonly Used in Small Batch CNC Machining

Small batch CNC machining can accommodate a wide range of materials, including metals, plastics, and composites. Some of the most commonly used materials include:

– Metals

Aluminum, stainless steel, titanium, and brass are popular choices for small batch production. These materials are valued for their corrosion resistance, strength, and machinability, making them ideal for industries ranging from aerospace to medical devices.

– Plastics

Materials like acrylic, polycarbonate, nylon, and Delrin are frequently used for producing lightweight, durable, and precise parts. These materials are widely applied in industries such as consumer products, automotive, and electrical components.

– Composites

For high-performance applications that require strength and low weight, materials such as carbon fiber and fiberglass composites are often used in industries like aerospace and automotive manufacturing.

Surface Finishes for Small Batch CNC Machining

To enhance the functionality and appearance of machined parts, various surface finishes can be applied, such as anodizing, powder coating, bead blasting, and electroplating. These finishes not only improve the aesthetic appeal of parts but also enhance their durability, resistance to corrosion, and overall performance.

Conclusion

Small batch CNC machining is an essential manufacturing solution for businesses seeking precision, flexibility, and cost-effective production for low volumes. Whether you need prototypes, custom parts, or low-volume production runs, CNC machining offers unparalleled benefits, such as reduced costs, rapid prototyping, and the ability to accommodate design changes quickly. At Topmetalstamping, we are committed to providing top-tier CNC machining services tailored to your specific needs. Contact us today to discuss your project, and let’s collaborate to turn your ideas into high-quality, precision-engineered products.