Overview:

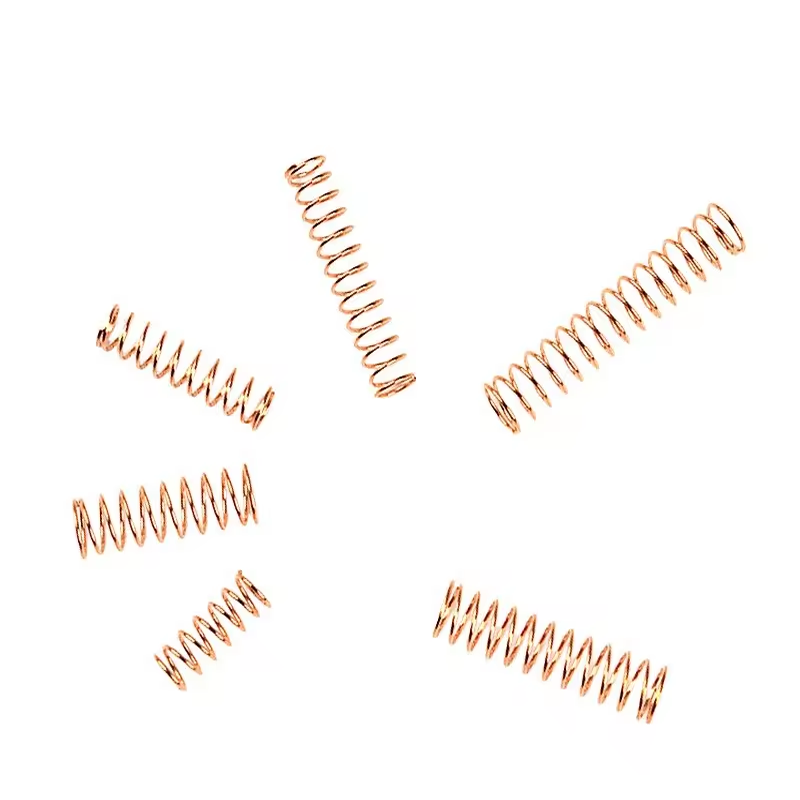

Custom copper wire forming springs are precision-engineered springs made from high-quality copper wire, designed to meet the specific requirements of various applications, including in connecting devices. These springs are widely used in industries where reliable electrical connections and durability are crucial, such as automotive, electronics, and industrial equipment.

Our manufacturing capabilities allow for customization of copper wire forming springs in a variety of sizes, surface finishes (including electroplating, tin plating, and nickel plating), and designs to suit your specific needs. With advanced production techniques and a commitment to quality, we ensure that every spring delivers superior performance, reliability, and longevity for your connecting devices.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Spring Steel, Stainless Steel, Aluminum, etc. |

| Finish | Custom (Customer’s Request) |

| Certificates | IATF16949, ISO9001 |

| Quality Control | 100% Inspection |

| Transportation | Express, Ocean, and Air |

| Size | Custom (Customer’s Request) |

| Packing | Custom |

Production Process:

- Material Selection: Choose the appropriate copper wire or alloy, ensuring it meets the necessary electrical conductivity, strength, and durability requirements for the specific application.

- Wire Forming: The copper wire is fed into a spring forming machine, where it’s shaped into the desired spring configuration, such as compression, tension, or torsion springs, based on customer specifications.

- Heat Treatment: The formed springs undergo a heat treatment process to improve their mechanical properties, such as strength and elasticity, ensuring they perform reliably over time.

- Surface Treatment: The springs are then subjected to surface finishing processes like electroplating, tin plating, or nickel plating, depending on customer requirements. These treatments enhance corrosion resistance and improve electrical conductivity.

- Quality Control and Inspection: Each spring is meticulously inspected to ensure it meets precise dimensional and functional requirements. This includes checks for size, tension, and spring force.

- Packaging and Shipping: The finished springs are carefully packed according to customer specifications, ensuring they are securely delivered for integration into connecting devices.

Surface Treatment Options:

- Electroplating: A process where a thin layer of metal, such as nickel or tin, is deposited onto the surface of the spring to enhance corrosion resistance and improve electrical conductivity.

- Nickel Plating: This provides a durable, corrosion-resistant coating that improves the spring’s longevity and ensures stable performance, especially in harsh environments.

- Tin Plating: Tin plating enhances corrosion resistance, particularly in moisture-prone environments, and ensures better solderability for electronic applications.

- Passivation: A chemical treatment that enhances the natural oxide layer on copper springs, increasing corrosion resistance and improving overall durability.

Why Choose Us?

With years of experience, Topmetalstamping delivers exceptional customer service, unmatched quality, and fast turnaround times for your wire forming projects. We adhere to ISO-9001, ISO-14001, and IATF16949 standards, ensuring that every stage of our manufacturing process is rigorously monitored for consistent quality before delivery.

We specialize in producing wire forms of all shapes and sizes, no matter the complexity, offering expert support from prototyping to full-scale production. With the ability to handle mass production of up to 50 million parts, we are equipped to meet your high-volume needs.Contact us today to discover how our advanced wire forming solutions can support your project’s success.

Reviews

There are no reviews yet.