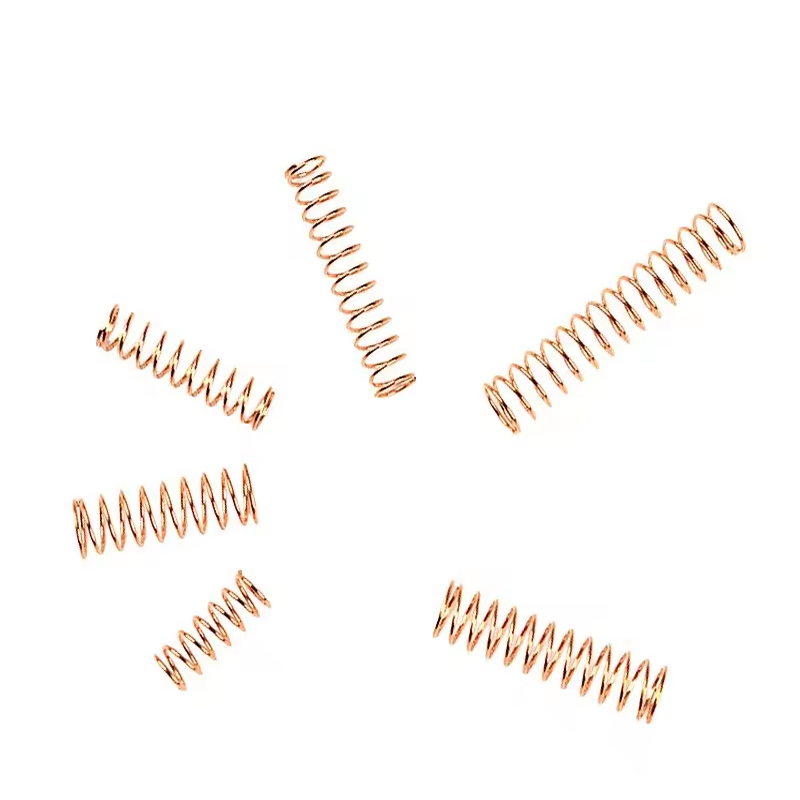

Product Overview:

Custom copper wire forming springs are meticulously crafted components, engineered from premium copper wire to meet the unique specifications of diverse applications, particularly in establishing secure and durable electrical connections. These springs are indispensable in industries where precision, reliability, and long-term performance are essential, such as automotive, electronics, and industrial machinery.

At our facility, we offer tailored copper wire forming springs in a range of dimensions, surface finishes (including electroplating, tin plating, and nickel plating), and configurations to match your exact requirements. Utilizing advanced manufacturing techniques and a strong commitment to excellence, we ensure that each spring provides exceptional functionality, reliability, and extended service life, making them ideal for use in critical connection systems.

Product Details:

- Place of Origin:Xiamen, China

- Brand Name:OEM

- Material Options:Spring Steel, Stainless Steel, Aluminum, and more

- Finish:Custom finishes available upon customer request

- Certificates:IATF16949, ISO9001

- Quality Control:100% inspection on all products

- Transportation Methods:Express, Ocean, and Air

- Size:Custom sizes based on customer requirements

- Packing:Customized packing according to customer preferences

Surface Treatment Options:

- Electroplating: This process involves applying a thin metal coating, such as nickel or tin, onto the surface of the spring. It significantly enhances corrosion resistance while improving electrical conductivity for reliable performance in various applications.

- Nickel Plating: A highly durable coating that provides superior resistance to corrosion, nickel plating extends the lifespan of springs and ensures consistent performance, even in challenging environmental conditions.

- Tin Plating: This treatment improves the spring’s resistance to corrosion, especially in humid or moisture-prone settings. It also enhances the spring’s solderability, making it an ideal choice for electronic and electrical applications.

- Passivation: A chemical treatment applied to copper springs that strengthens the natural oxide layer, boosting corrosion resistance and overall durability. This process is particularly effective in environments that require enhanced protection from corrosion.

Production Process:

- Material Selection: The first step in the production of custom copper wire forming springs is the careful selection of high-quality copper wire or alloys. These materials are chosen based on their ability to meet the specific demands for electrical conductivity, mechanical strength, and long-lasting durability, ensuring optimal performance for the intended application.

- Wire Forming: Once the material is selected, the copper wire is fed into a precision spring-forming machine. The wire is then meticulously shaped into the required spring configuration, whether it be compression, tension, or torsion springs. The design is tailored to meet the exact specifications provided by the customer.

- Heat Treatment: To enhance the mechanical properties of the springs, such as strength and elasticity, they undergo a controlled heat treatment process. This step is crucial in ensuring that the springs will perform consistently and reliably over extended periods, even under demanding conditions.

- Surface Treatment: Following heat treatment, the springs are subjected to surface finishing treatments, including electroplating, tin plating, or nickel plating, based on customer preferences. These surface treatments provide an added layer of protection against corrosion and enhance the electrical conductivity of the springs, contributing to their overall functionality and durability.

- Quality Control and Inspection: Every spring undergoes rigorous quality control checks to ensure it meets the precise specifications for both size and performance. Detailed inspections are carried out to evaluate the spring’s dimensions, tension, and force to guarantee optimal functionality in the final application.

- Packaging and Shipping: Once the springs pass inspection, they are carefully packaged according to the customer’s specifications. Each unit is securely packed to prevent damage during transit, ensuring the springs arrive safely and ready for integration into connecting devices or other electronic systems.

Factory Show:

We operate a wide range of advanced facilities to ensure top-tier production quality. Our equipment includes 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding tools, welding and polishing equipment, and ultrasonic cleaning systems.

In addition, we provide a variety of metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities guarantee consistent finishes, superior corrosion resistance, and compliance with industry standards.

With automated production lines, advanced machinery, rigorous quality control, and high-quality plating processes, we ensure our metal stamping products meet the highest standards. Our operations are certified under ISO 9001 and IATF 16949, further assuring product excellence.

Reviews

There are no reviews yet.