Overview:

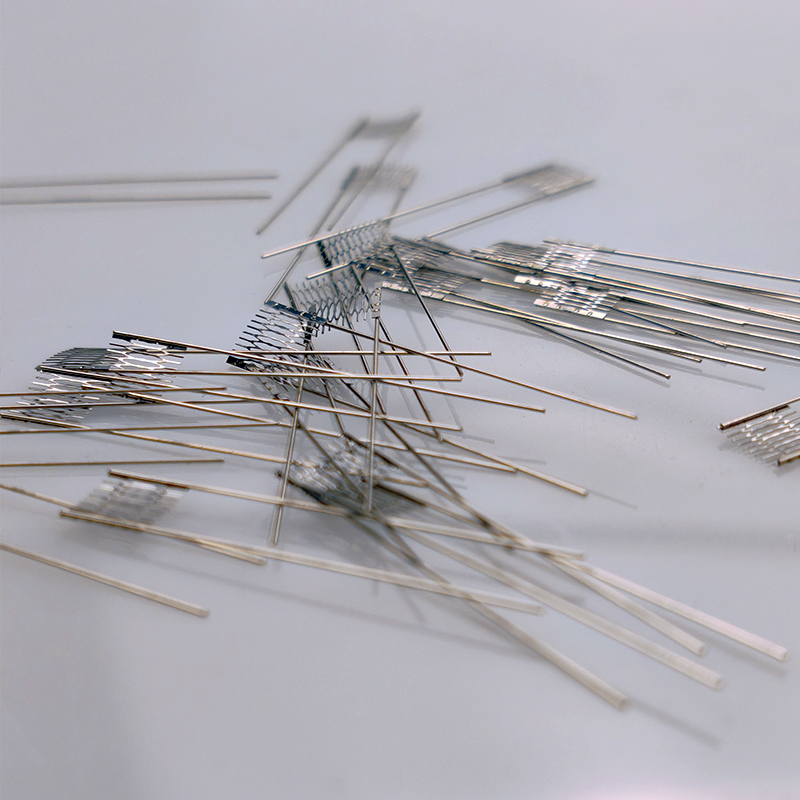

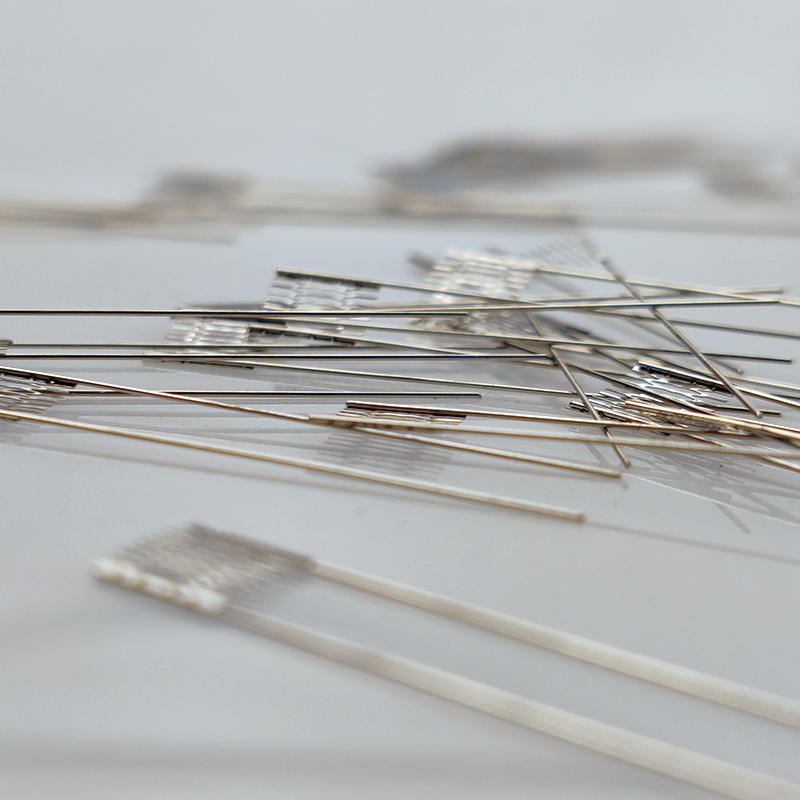

Stainless Steel Heating Elements are specialized components designed for heating applications, primarily manufactured using processes such as resistance wire winding and welding. These heating elements are known for their excellent durability and corrosion resistance, making them ideal for various environments. Our stainless steel heating elements exhibit high thermal efficiency, longevity, and the capability to withstand high temperatures, ensuring reliable performance over time. We also offer custom solutions tailored to meet specific requirements, including size, material selection, and surface treatments, ensuring that our products align perfectly with your application needs.

Features:

| Product Specification | Details |

| Custom Sizes | Available upon request |

| Common Surface Treatments | Polishing, anodizing, sandblasting, passivation |

| Manufacturing Processes | Resistance wire winding, welding |

| Material Options | 304 stainless steel, 316 stainless steel, other alloys upon request |

| OEM Brand Acceptance | Yes |

| MOQ | Based on design specifications |

| Color Options | Standard silver finish; custom colors available upon request |

| Accepted Drawing Formats | CAD, PDF, DXF, DWG |

| Custom Packaging | Available upon request |

Production Process:

- Material Selection: Choosing high-quality stainless steel, often 304 or 316 grade, based on the application requirements.

- Wire Drawing: Reducing the diameter of the stainless steel wire to the desired size through a series of dies.

- Resistance Wire Winding: Winding the drawn wire into specific configurations to create the heating element design.

- Welding: Joining the wound wire to terminal ends using high-precision welding techniques to ensure electrical connectivity.

- Surface Treatment: Applying surface finishes such as polishing or anodizing to enhance corrosion resistance and improve aesthetics.

- Quality Control: Conducting rigorous testing and inspections throughout the manufacturing process to ensure compliance with safety and performance standards.

- Final Assembly: Integrating the heating elements into their respective housings or enclosures if required.

- Packaging: Custom packaging solutions are applied to protect the elements during transportation and storage.

Quality Assurance:

When conducting quality testing for our Stainless Steel Heating Elements, we utilize several advanced machines and methods to ensure compliance with industry standards. The primary processes include visual inspections using high-resolution cameras to identify any surface defects, electrical testing with multimeters to verify resistance and continuity, and thermal imaging to assess heat distribution during operation. Additionally, we perform mechanical testing using tensile testers to measure the material’s strength and flexibility. Our rigorous quality control also includes corrosion resistance tests conducted in salt spray chambers to simulate harsh environmental conditions. Each of these methods is essential for confirming the durability, efficiency, and safety of our heating elements before they are approved for use in various applications.

Factory Show:

Reviews

There are no reviews yet.