Overview:

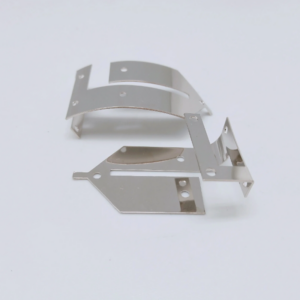

Horn brackets, also called hangers, are essential components used across various industries, including construction, automotive, electronics, and sensors. They provide support, secure parts, protect against stress, and tie structural elements together.As a leading supplier of stamped metal parts and assemblies, we specialize in manufacturing stainless steel brackets for diverse applications, ensuring durability and reliability.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Service | OEM |

| Brand Name | OEM |

| Use | Sensors |

| Material | Stainless Steel |

| Weight | Custom |

| Tension | High |

| Size | Custom |

| MOQ | Small Order Can be Accepted |

| Application | Automotive, Electronics, Industrial, Sensors |

| Durability | High resistance to corrosion and wear |

| Customization | Available for design, size, and finish |

| Finish Options | Polished, Brushed, Anodized, Powder Coated |

| Certifications | ISO 9001:2015, RoHS |

| Production Capacity | 100,000 pieces/month |

| Shipping Terms | By Sea, Express |

| Lead Time | 7-25 Working Days |

Advantages of Bracket:

- More cost-effective than aluminum

- Exceptionally durable and tough

- Superior tensile strength

Production Process:

-

Design and Prototyping

The process begins with designing the bracket according to specific sensor application requirements. Using CAD (Computer-Aided Design) software, engineers create a prototype that meets the necessary dimensions, functionality, and performance standards.

-

Material Selection

High-quality stainless steel is selected for its strength, corrosion resistance, and suitability for the application. The material is sourced based on the desired specifications for the final product.

-

Cutting and Shaping

The stainless steel sheet is cut to the required dimensions using precision machinery, such as laser cutting or water jet cutting. The material is then shaped through stamping, punching, or CNC machining to achieve the desired form.

-

Forming and Bending

Using specialized bending equipment, the bracket is formed to its final shape. This step ensures the bracket fits precisely within the sensor assembly and meets the mechanical strength and stability required for its application.

-

Surface Treatment

The stainless steel horn bracket undergoes surface treatment processes such as polishing, anodizing, or powder coating. This enhances its corrosion resistance, aesthetics, and durability, ensuring it meets environmental and performance standards.

-

Quality Control and Testing

After forming and surface treatment, the bracket undergoes rigorous inspection and testing to ensure it meets all specifications. This includes dimensional checks, tension tests, and quality assurance procedures such as salt spray testing for corrosion resistance.

-

Assembly and Final Inspection

The custom stainless steel horn brackets are assembled into their final configuration and undergo a final inspection. This ensures they meet all functional requirements before being shipped to customers.

-

Packaging and Delivery

The brackets are carefully packaged to prevent any damage during transport. They are then shipped according to the agreed delivery terms, ensuring timely delivery to customers.

Surface Treatment Options:

-

Polishing

This process smooths the surface of the stainless steel to enhance its appearance and remove any rough edges. It also provides a shiny, mirror-like finish that improves both the aesthetic quality and corrosion resistance.

-

Anodizing

Anodizing is an electrochemical process that increases the thickness of the natural oxide layer on the surface of stainless steel. This improves its resistance to corrosion and wear while providing a more durable finish.

-

Powder Coating

Powder coating involves applying a dry powder that is then cured under heat to form a protective layer. This treatment offers excellent protection against scratches, chipping, fading, and corrosion, making it ideal for sensor applications exposed to harsh environments.

-

Passivation

Passivation involves treating stainless steel with a chemical solution to remove free iron from the surface and enhance its natural corrosion resistance. This process improves the material’s durability, particularly in harsh or corrosive environments.

Our Factory:

We maintain a state-of-the-art manufacturing facility equipped with a wide array of advanced machinery to guarantee top-tier production quality. Our plant houses 25 punch presses ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding tools, welding equipment, polishing stations, and ultrasonic cleaning systems.

Alongside our core manufacturing capabilities, we provide an extensive range of metal plating services designed to enhance the durability, appearance, and performance of our stamped metal products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure uniform finishes, superior corrosion resistance, and adherence to industry standards.

With a combination of fully automated production lines, advanced machinery, stringent quality control processes, and high-quality plating techniques, we are committed to delivering stamped metal products of exceptional quality.

Reviews

There are no reviews yet.