Description:

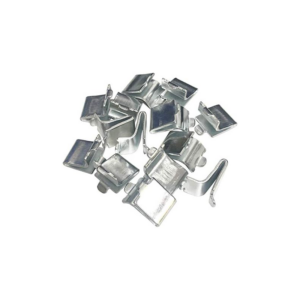

Our stainless steel terminal clips, treated with acid passivation, are engineered for exceptional corrosion resistance and long-lasting reliability. These clips are ideally suited for demanding applications in industries such as automotive, electronics, telecommunications, and energy. Utilizing advanced stamping and acid passivation techniques, we ensure that each clip meets the highest standards of durability and performance. We also offer bespoke manufacturing services to accommodate your specific design requirements, delivering customized, high-quality solutions for a variety of applications.

Characteristics:

- Material:Stainless Steel

- Mold:In-House Die Making

- Surface Treatment:Acid Passivation

- Manufacturing Process:Forming Process

- Tolerances:02mm

- Customization:Highly Welcome

- Alternative Materials:Copper, Stainless Steel, Carbon Steel, Aluminum, etc.

- Applications:Automotive, Agriculture, Furniture, Machinery

- Press Capabilities:25-ton to 300-ton presses

- Sample Availability:Samples Provided

- Service Type:OEM

- File Formats Supported:CAD, SolidWorks, PDF, etc.

- Packaging:Custom Packaging Available

- Trademark:OEM

- Origin:Xiamen, China

Why Partner with Us?

- Premium OEM Solutions:Tailored to meet your specific needs with exceptional precision and quality.

- Expedited Delivery:Timely shipping to ensure your project stays on track.

- Rigorous Quality Assurance:Certified to ISO9001 and IATF16949 standards, guaranteeing consistent, top-tier quality.

- Cost-Effective Pricing:Competitive rates without compromising on quality, helping you achieve your business goals.

Manufacturing Process:

- Material Selection: Premium stainless steel is selected for its superior corrosion resistance, strength, and longevity, ensuring reliable performance even in challenging environments.

- Custom Die Design & In-House Fabrication: We create and manufacture precise custom die sets in-house, tailored to meet exact specifications for terminal clips, ensuring uniformity and accuracy in production.

- Stamping & Forming: The stainless steel material is processed through high-pressure stamping presses, ranging from 25 to 300 tons, to precisely shape and form the clips, ensuring consistency and structural integrity.

- Acid Passivation Treatment: After stamping, the clips undergo an acid passivation treatment, which eliminates surface impurities and significantly enhances corrosion resistance, ensuring long-lasting durability in harsh environments.

- Rigorous Quality Control & Tolerancing: Each clip is meticulously inspected for dimensional accuracy, typically within ±0.02mm, and thoroughly tested for performance and surface quality to meet strict standards.

- Surface Finishing: To further optimize the clips’ appearance and resilience, we offer additional surface treatments, such as polishing or specialized coatings, based on customer preferences.

- Final Quality Inspection & Packaging: The final product is subjected to a thorough quality inspection before being packaged according to customer specifications, ensuring secure and efficient delivery.

Factory Overview:

Our facility is equipped with cutting-edge machinery to ensure the highest standards of production. This includes 25 high-performance punch presses ranging from 25 to 300 tons, precision wire EDM machines, advanced grinding equipment, and ultrasonic cleaning systems. These technologies enable us to produce parts with exceptional accuracy and quality.

We also offer a comprehensive range of metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These finishing processes not only improve the durability and corrosion resistance of our products but also enhance their aesthetic appeal and functionality.

With our state-of-the-art equipment, rigorous quality control protocols, and expert plating processes, we consistently deliver superior metal stamping products that meet the highest industry standards.

Reviews

There are no reviews yet.