Description:

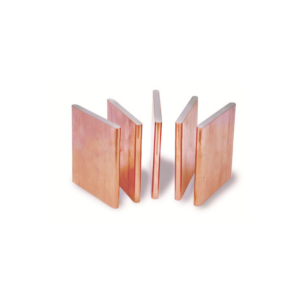

Tin-plated copper busbars offer enhanced flexibility and efficiency for electricity distribution compared to more traditional and permanent installation methods. Also known as bus bars or buss bars, these metal strips—typically made from copper, brass, or aluminum—serve both as conductors and grounding elements.At Topmetalstamping, we prioritize the reliability and safety of your power distribution systems by providing high-quality busbars. As a leading supplier of stamped metal components and assemblies, we specialize in producing robust busbars that meet the demands of various industries, ensuring optimal performance even in challenging environments.

Features:

- Processing Type: Metal Stamping

- Material: Copper

- Mould: Simple Single Process Dies

- Surface Processing: Tin-Plated

- Fine Blanking: Open

- Industry: Electronic Parts

- Tolerances: ±0.01mm

- Customized: Yes

- Finish: Bare, Tin Plating, Nickel Plating

- Insulation: PE Heat Shrink Tube, PVC, Epoxy Powder

- Size: Customized

- Transport Package: Custom

- Specification: Customized

- Trademark: OEM

- Origin: Xiamen, China

- Production Capacity: 10,000 PCS/Day

Quality Assurance:

At Topmetalstamping, we prioritize quality in every aspect of our manufacturing process. Each project begins with a comprehensive feasibility assessment to ensure manufacturability, followed by a run-at-rate study to validate quality before moving into full-scale production. This approach allows our quality control and production teams to closely monitor and maintain process integrity, ensuring efficient operations and consistent, conforming parts.

Our quality management system incorporates advanced technologies such as custom camera vision systems and sensor-based inspections, which are seamlessly integrated with our stamping machinery. This ensures precise monitoring of part features and dimensions, enabling us to achieve 100% defect-free production.

Certified to ISO 9001 and IATF 16949 standards, Topmetalstamping upholds the highest industry benchmarks. We are committed to delivering high-performance copper busbars and other stamped components that are tailored to meet the specific needs of our customers.

Other Surface Treatment Options:

- Bare Copper– Uncoated copper, offering a natural finish for immediate use or further processing.

- Nickel Plating– A robust, corrosion-resistant coating that enhances the durability and conductivity of copper busbars.

- Silver Plating– Provides exceptional conductivity and superior resistance to oxidation, making it ideal for high-performance electrical applications.

- Epoxy Powder Coating– A protective, insulating layer that offers corrosion resistance and is commonly used in applications where electrical insulation is crucial.

Why Partner with Us?

- Competitive factory pricing for cost-efficient solutions.

- Uncompromising quality assurance with first article, in-process, and final inspections.

- Dedicated customer service, with specialists managing pre-sales, quality, logistics, and post-sale support.

- Timely delivery and end-to-end service for a seamless experience.

Our Manufacturing Facility:

Our state-of-the-art facility is fully equipped to deliver exceptional production quality. We operate 25 punch presses, ranging from 25 to 300 tons, along with precision wire EDM machines, grinding tools, welding and polishing stations, and ultrasonic cleaning systems.

Beyond our advanced manufacturing capabilities, we offer an array of metal plating options designed to enhance the performance, appearance, and durability of our stamped components. These include electroplating, zinc, nickel, chrome plating, and anodizing. Our sophisticated plating facilities ensure uniform finishes, superior corrosion resistance, and full adherence to industry standards.

This combination of automated production lines, advanced machinery, rigorous quality controls, and high-performance plating technologies guarantees the delivery of premium metal stamping products.

Reviews

There are no reviews yet.