Overview:

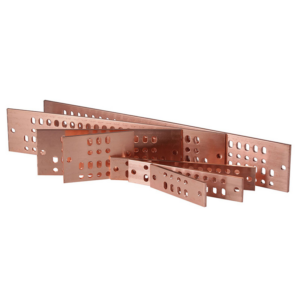

Deep drawing protective stamping sleeves are precision-engineered components manufactured using the deep drawing process, which involves forming sheet metal into seamless, durable shapes through a series of progressive stamping operations. These sleeves are widely used in energy storage devices due to their exceptional durability, precise dimensions, and ability to provide reliable protection against physical and environmental stresses. At Topmetalstamping, we offer custom manufacturing services for protective stamping sleeves, including a wide range of sizes, materials, and surface finishes to meet your specific needs. Contact us today to discuss your custom requirements for high-quality deep drawing sleeves tailored to your application.

Characteristics:

| Specification | Details |

| Place of Origin | Xiamen, China |

| Customized Support | OEM |

| Brand Name | OEM |

| Material | Stainless Steel 304 |

| Size | Design-based customization |

| Surface Treatment | High Polishing |

| Processing | Deep Drawing, Stamping |

| Drawings | Can be provided for free |

| MOQ | According to your requirement |

| Certification | ISO, ROHS |

| Quality Control | 100% Manual Quality Check |

| Sample | Available |

Production Process:

-

Material Selection and Preparation

High-quality stainless steel or other specified materials are selected and prepared, ensuring the material meets the required mechanical properties and surface finish standards.

-

Blanking

Sheets of metal are cut into precise blanks to match the desired size and shape for the deep drawing process.

-

Deep Drawing and Stamping

The metal blanks are progressively formed into protective sleeves using specialized deep drawing and stamping techniques, ensuring uniform thickness and structural integrity.

-

Trimming and Deburring

The formed sleeves are trimmed to remove excess material, and deburring is performed to ensure smooth edges and a polished finish.

-

Surface Treatment

High-polishing or other specified surface treatments are applied to enhance the appearance and corrosion resistance of the sleeves.

-

Quality Inspection

A 100% manual quality check is conducted to verify dimensional accuracy, surface quality, and compliance with ISO and ROHS standards.

Surface Treatment Options:

-

High Polishing

Provides a smooth, reflective finish that enhances corrosion resistance and improves the sleeve’s aesthetic appeal.

-

Anodizing

Creates a durable oxide layer on the surface, offering excellent protection against wear and environmental degradation while allowing for customizable colors.

-

Electroplating

Deposits a thin metal coating, such as nickel or chromium, to enhance conductivity, corrosion resistance, and surface durability.

-

Powder Coating

Applies a uniform, protective layer of powder-based paint, delivering enhanced resistance to scratches, chemicals, and environmental exposure.

Our Factory:

We operate a fully equipped facility designed to deliver the highest quality production standards. Our advanced capabilities include 25 punch presses with capacities ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems, ensuring precision and efficiency at every stage of manufacturing.

Our expertise extends to a comprehensive range of metal plating processes that enhance the durability, aesthetics, and performance of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities guarantee consistent finishes, exceptional corrosion resistance, and full compliance with industry standards.

By combining professional, automated production lines, cutting-edge machinery, stringent quality control protocols, and high-quality plating solutions, we deliver metal stamping products that meet the most demanding requirements for precision and reliability.

Reviews

There are no reviews yet.