Description:

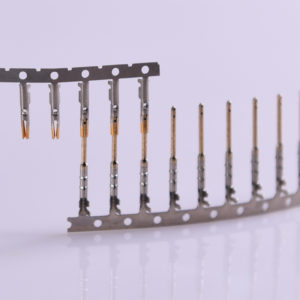

Electrical Wire Lug Metal Connectors are essential for creating secure and reliable electrical connections in industries such as automotive, industrial, and renewable energy. Made from high-quality materials like copper, brass, and aluminum, these connectors are manufactured using advanced processes such as stamping and electroplating. We offer custom services to tailor the size, color, and surface treatment—including zinc, nickel, or chrome plating—to suit your specific needs. Trust us to deliver durable, high-performance connectors that meet your exact specifications.

Characteristics:

| Category | Details |

| Application | Wire Connecting |

| Character | Durable |

| Production Process | Cold Pressing |

| Shape | Custom |

| Certification | ISO9001, IATF16949 |

| Brand | OEM |

| Color | Gold Plated, Nickel Plated, Plated Tin, Silver Plated |

| Special | OEM Service Offered |

| Usage | Connecting Cable |

| Lead Time (Days) | 15 Days |

| MOQ | Negotiable |

| Size | Custom |

| Transport Package | Custom |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 10,000 PCS/Day |

Advantages Of Wire Lug Metal Connector:

-

Reliable Electrical Conductivity

Electrical wire lugs are made from high-conductivity materials such as copper or brass, ensuring a reliable and efficient transfer of electrical signals and energy.

-

Durability and Corrosion Resistance

With advanced surface treatments like nickel, tin, or gold plating, these connectors offer superior resistance to corrosion, ensuring long-term durability even in harsh environments.

-

Customizable for Specific Applications

These connectors can be tailored to meet precise customer specifications, including size, color, and plating options, making them ideal for a wide range of applications.

-

Ease of Installation and Secure Connection

The design of electrical wire lugs ensures a secure and easy connection with cables, minimizing the risk of loose connections and improving overall system reliability.

Production Process:

-

Material Selection

The first step is to choose the appropriate material, such as copper, brass, or aluminum, based on the connector’s electrical conductivity and application requirements.

-

Die Preparation

Precision dies are designed and manufactured to shape the wire lugs accurately during the stamping process.

-

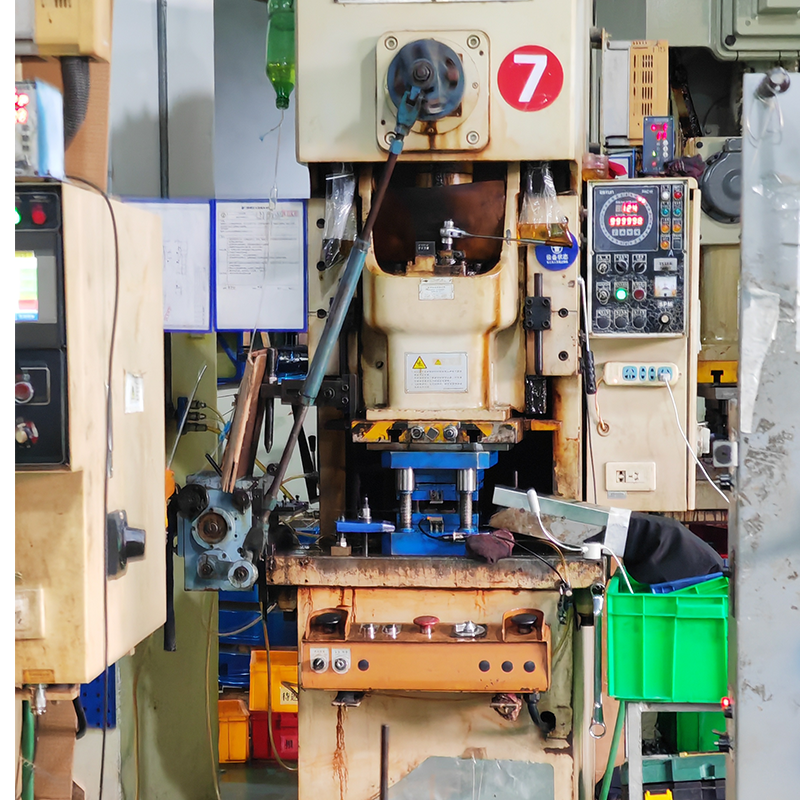

Cold Pressing

The raw material is fed into stamping machines where it’s cold pressed into the desired shape, ensuring dimensional accuracy and a smooth finish.

-

Hole Punching

The connectors undergo a punching process to create the required holes for cable insertion, ensuring a precise fit.

-

Crimping

The connector is crimped onto the wire to create a secure, long-lasting electrical connection that ensures reliability and conductivity.

-

Surface Treatment

To enhance durability and resistance to corrosion, surface treatments such as tin plating, nickel plating, gold plating, or silver plating are applied.

-

Inspection and Testing

Each connector undergoes strict quality control checks, including dimensional accuracy, pull tests, and electrical conductivity testing, to ensure performance and compliance with industry standards.

-

Customization

The connectors can be customized in terms of size, color, and surface finish based on customer specifications.

-

Packaging and Delivery

Finally, the finished wire lugs are carefully packaged, ensuring safe transport and delivery within the agreed timeframe.

Why Choose Us?

– Advanced Manufacturing Technology

We use four-slide/multi-slide stamping to efficiently produce high-precision wire lug metal connectors and components, ensuring cost-effective, high-volume production.

– In-House Tooling & Die Capabilities

Our in-house tooling and die-making allow quick design adjustments and faster turnaround, ensuring high-quality results without extra costs.

– ISO-Certified Facilities

Our facilities are ISO 9001, ISO 14001, and IATF 16949 certified, guaranteeing the highest quality standards for our wire lug metal connectors.

– Cost-Efficient Production & Just-in-Time Delivery

With efficient production techniques and a robust MRP system, we offer cost-effective solutions and reliable, timely delivery aligned with customer schedules.

Reviews

There are no reviews yet.