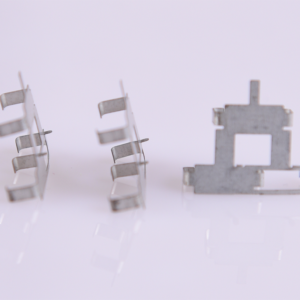

Electronic stamped contacts are precision-engineered components used to establish reliable electrical connections in a wide range of devices. Made from high-quality materials such as copper and brass, these contacts are produced through a stamping process that ensures accuracy and durability. They are commonly used in consumer electronics, automotive systems, telecommunications, and industrial automation to support signal transmission, power distribution, and system performance. Available in various surface finishes like gold, silver, nickel, and tin plating, electronic stamped contacts offer excellent conductivity and corrosion resistance, making them ideal for high-performance applications.

Basic Information:

- Material:Copper-1100, Copper-5191, Brass-6265, Brass-7275

- Post Process:Gold plating, Silver plating, Nickel plating, Tin plating

- Surface Finish Options:Gold Plating, Silver Plating, Nickel Plating, Tin Plating

- Sample Availability:Available

- Tolerance:±0.001 mm

- Size:Customizable as per requirement

- Manufacturing Approach:Metal Stamping, Cutting, Punching, Bending, Welding

- Transport Packaging:OPP Bag, Box, or Custom

- Specification:Customized

- Origin:Xiamen, China

- Applications:Consumer electronics, automotive electronics, industrial automation, telecommunications, medical equipment, aerospace, and energy systems.

The Production Process for Our Metal Stamping Parts:

-

Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

-

Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

-

Material Preparatio

– Select and prepare metal sheets according to the required specifications.

-

Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

-

Forming and Shapin

– Perform bending, punching, and stamping to achieve the desired shapes and features.

-

Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

-

Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

-

Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

-

Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

-

After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

What We Offer

We are a trusted supplier specializing in the production of precision hardware components. Committed to consistently meeting your needs, we offer tailored solutions that align with industry-specific requirements. Our core services are designed to deliver superior performance, quality, and reliability.

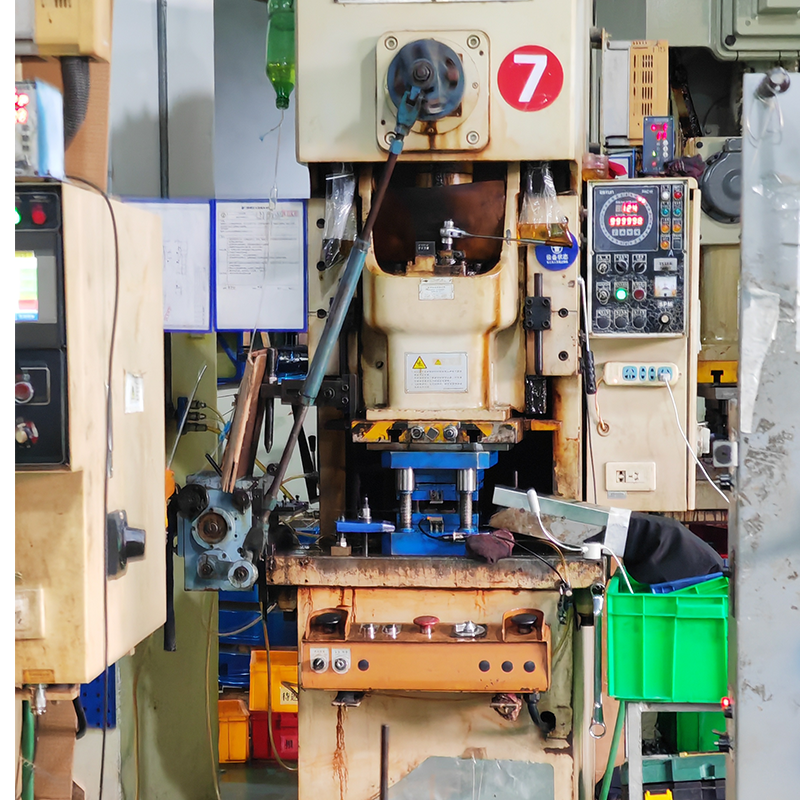

Our facility features 25 punch presses, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. With advanced processing and testing capabilities, we deliver reliable, high-performance metal stamping solutions backed by stringent quality assurance.

Reviews

There are no reviews yet.