Surface Treatment Options:

1.Anodization

Enhances aluminum’s natural oxide layer for improved corrosion resistance and wear properties, available in various colors.

2.Powder Coating

Durable finish resistant to chips, scratches, and fading, offering extensive color and texture choices.

3.Electroplating

Deposits metal layers like nickel, zinc, or chrome to enhance appearance, corrosion resistance, and surface hardness.

4.Passivation

Chemical treatment to boost corrosion resistance without altering appearance.

5.Polishing

Creates a smooth, reflective surface for improved aesthetics.

6.Brushing

Uniform satin texture that hides fingerprints and minor scratches.

7.Painting

Customizable colors and protective coating.

8.Sandblasting

Creates a textured finish for enhanced adhesion and unique appearance.

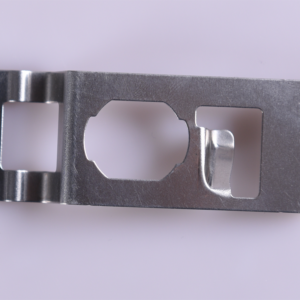

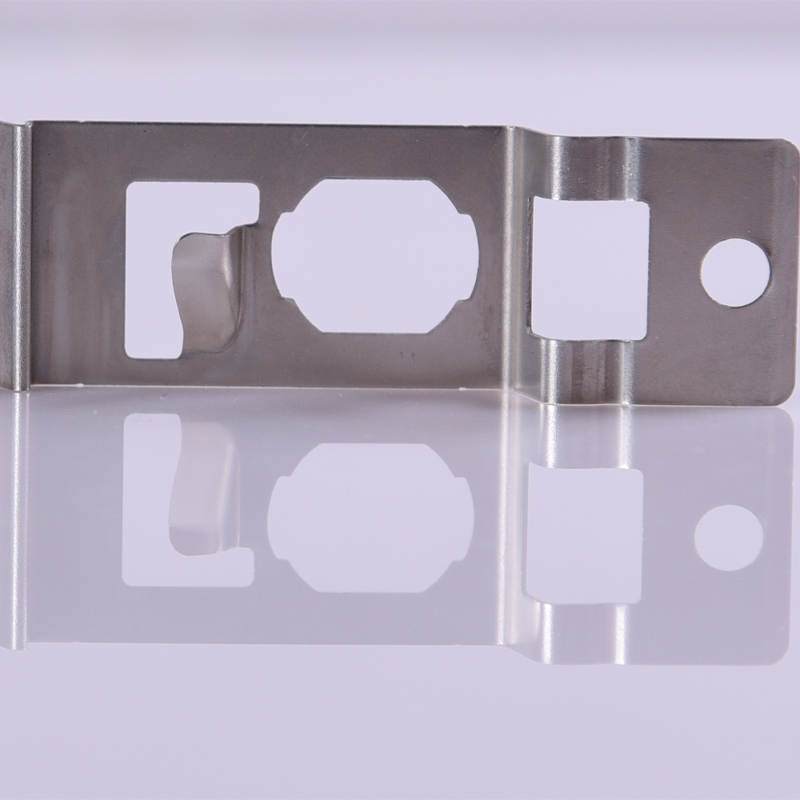

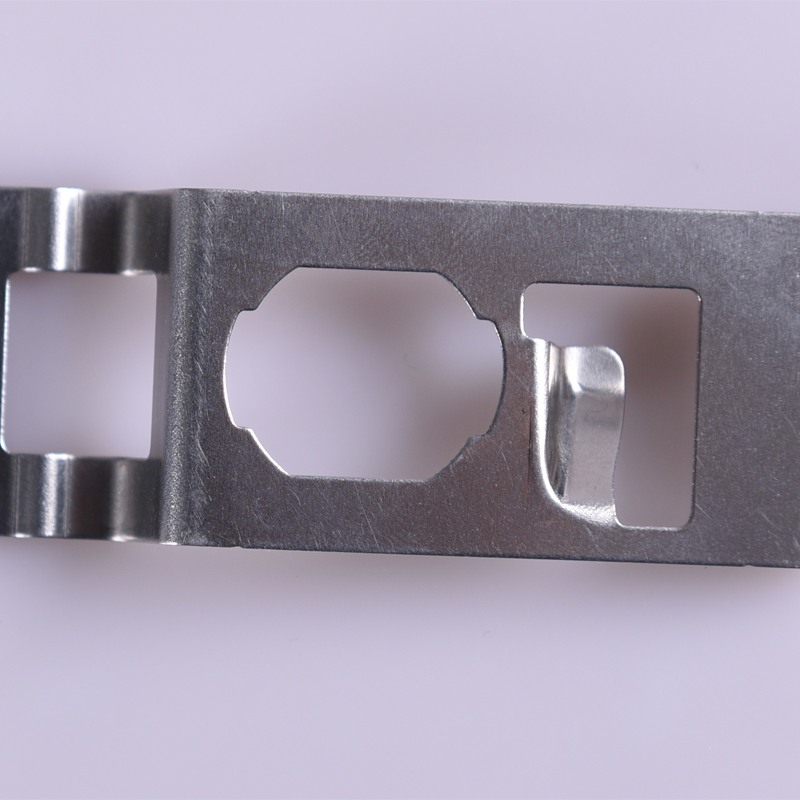

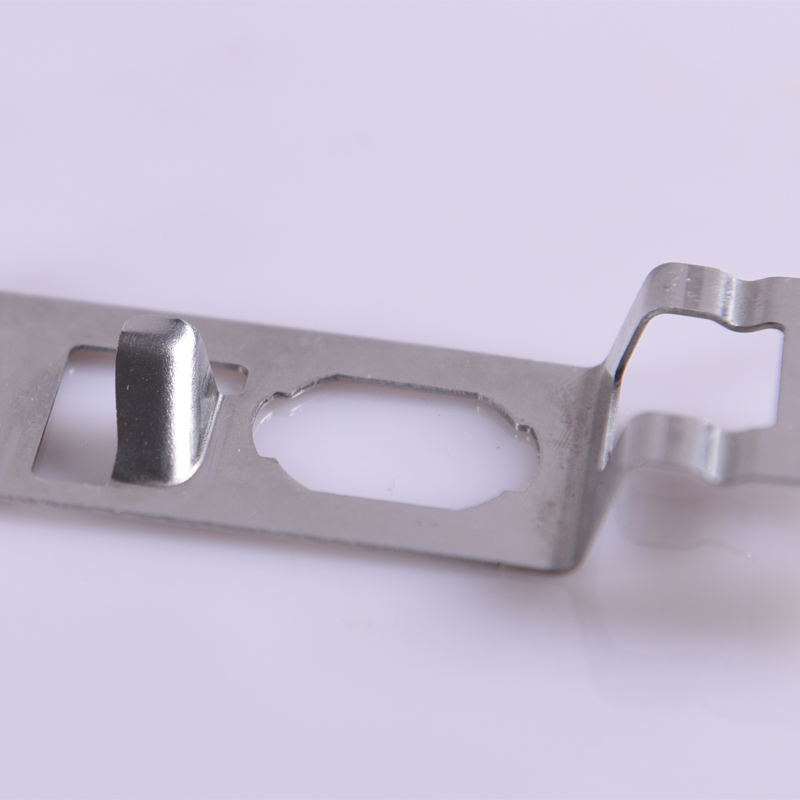

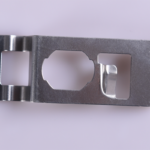

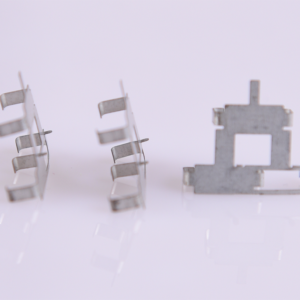

Materials and Customization

Materials: Carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy

Customization: Sizes and dimensions can be tailored according to customer requirements

Applications: Network devices, communication equipment, computers, household appliances, distribution systems, educational toys, among others

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.

Reviews

There are no reviews yet.