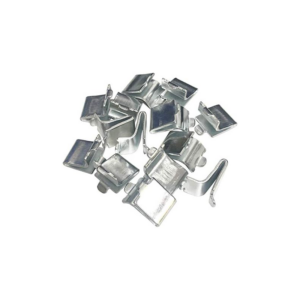

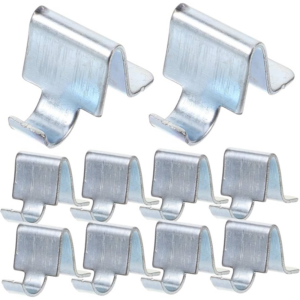

Overview:

Gold-plated metal clips for electronic communication equipment are precision components electroplated with a thin gold layer to enhance electrical conductivity, corrosion resistance, and durability. These clips are typically produced through stamping or molding, followed by gold plating, ensuring superior performance in demanding environments.We provide custom gold-plating services for metal clips, offering a range of sizes and surface treatments to meet your specific requirements. Our expert team ensures that every product adheres to the highest quality standards and is delivered on schedule, delivering tailored solutions for the electronic communication sector.

Details:

| Item | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Application | Electronic Communication Equipment |

| Certificate | ISO9001 / IATF16949 |

| Surface Treatment | Nickel Plating / Chrome Gold Plated |

| Process | Progressive Stamping |

| Thickness | 0.1-12.0mm (as required) |

| Shape | OEM Sheet Metal Stamping & Bending |

| Material | Brass, Copper, Carbon Steel, Stainless Steel, etc. |

| Inspection | 100% Inspection Before Delivery |

Production Process:

-

Material Selection

High-quality materials such as brass, copper, carbon steel, or stainless steel are selected based on the specific requirements for conductivity, strength, and corrosion resistance.

-

Stamping/Forming

The chosen material is formed into the desired shape using a progressive stamping or molding process. This step ensures precise dimensions and smooth edges for the metal clips.

-

Surface Preparation

The clips undergo cleaning and surface treatment to remove any impurities, oils, or oxidation. This ensures proper adhesion of the gold plating and optimal performance.

-

Gold Plating (Electroplating)

A thin layer of gold is applied through an electroplating process. The clips are immersed in a gold-plating solution, where an electrical current causes gold ions to bond to the metal surface. This step enhances electrical conductivity, corrosion resistance, and durability.

-

Post-Plating Inspection

After plating, the clips are thoroughly inspected to ensure uniform gold coverage and that they meet strict quality standards. This step ensures the plating’s consistency and functionality.

-

Final Inspection & Quality Control

A final 100% inspection is conducted to check for any defects, including size, shape, and plating quality. Only clips that meet all specifications are approved for delivery.

-

Packaging & Delivery

The finished gold-plated metal clips are carefully packaged to prevent damage during transportation and are then delivered according to customer requirements.

Why Choose Us?

-

Custom OEM & Assembly Solutions

Specializing in tailor-made OEM solutions and comprehensive assembly services since 2000, we provide precision manufacturing to meet your unique requirements.

-

All-Inclusive Service Offering

We offer an extensive range of products, including stamping parts, CNC machined components, springs, shafts, fasteners, and more, ensuring a complete one-stop solution for your manufacturing needs.

-

Certified and Trusted Supplier

As a reliable second-tier supplier, we have successfully passed rigorous factory audits and hold key industry certifications, including RoHS and HE compliance, guaranteeing adherence to global standards.

-

Commitment to Quality Excellence

With certifications in ISO 9001:2015 and IATF 16949, we uphold the highest standards of quality management to ensure consistent and reliable production across all of our services.

Our Factory:

Our manufacturing facilities are equipped with a comprehensive array of advanced machinery to guarantee top-tier production quality. We operate 25 punch presses, ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. To further enhance the durability, appearance, and functionality of our metal stamping products, we offer a variety of plating processes, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure consistent finishes, superior corrosion resistance, and full compliance with industry standards. By combining automated production lines, advanced mechanical equipment, stringent quality control protocols, and premium plating capabilities, we consistently deliver metal stamping products that meet the highest industry standards.

Reviews

There are no reviews yet.