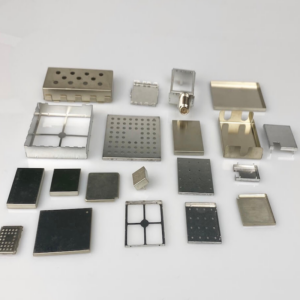

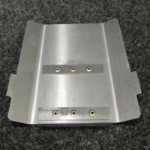

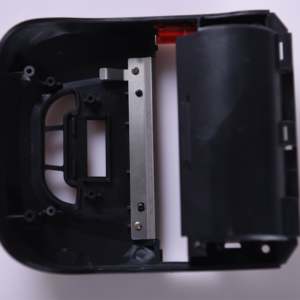

Metal stamping shielding cover case is a specialized enclosure crafted through metal stamping techniques. It serves as a protective casing designed to shield sensitive electronic components from electromagnetic interference (EMI) and radio frequency interference (RFI). This shielding solution is meticulously engineered to ensure precise fit and optimal performance, providing reliable protection for electronic devices in various applications, including telecommunications, automotive electronics, and consumer electronics.

Characteristics:

| Key Attributes | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM/ODM |

| Material | Aluminum, Brass, Bronze, Copper, Stainless steel |

| Surface Treatment | Color Anodize, Galvanized, Powder Coating, Chrome Plating… |

| Service | Custom Sheet Metal Fabrication Service |

| Application | Automotive, Medical, Telecom, Machine, etc |

| Thickness | 0.15mm – 0.5mm |

| Drawing Format | 2D (PDF/CAD), 3D (IGES/STEP) |

| MOQ | According to Your Demand |

| OEM/ODM | OEM/ODM Service Provided |

| Sample | Available |

| Size | Custom |

| Color | Custom |

Why Choose Us?

Cost Efficiency:

– Provides cost-effective solutions without compromising quality.

– Ensures budget-friendly options for various projects and requirements.

Quick Turnaround:

– Offers short production cycles for timely delivery of orders.

– Facilitates efficient project completion and turnaround times.

Premium Quality:

– Delivers superior quality products that surpass industry standards.

– Ensures top-notch performance and durability for long-lasting results.

Key Advantages:

– Low Minimum Order Quantity (MOQ) allows flexibility for small-scale projects.

– Dedicated after-sales support ensures customer satisfaction and assistance.

– Rigorous quality control measures guarantee product consistency and reliability.

Custom Process:

Supply Requirements Assessment:

– Evaluate and determine specific product requirements as per customer specifications and preferences.

– Collaborate with customers to gather detailed information and ensure alignment with desired outcomes.

Sample Validation:

– Conduct thorough validation of product samples to verify compliance with customer expectations and quality standards.

– Ensure that samples meet all specified criteria before proceeding with mass production.

Production and Quality Assurance:

– Execute comprehensive production processes while adhering to established quality standards and protocols.

– Implement rigorous quality inspection procedures at every stage of production to maintain product integrity and consistency.

Packaging and Logistics:

– Strategically package finished products according to customer preferences and shipping requirements.

– Organize efficient shipping and logistics processes to ensure timely and secure delivery to customers’ specified locations.

Reviews

There are no reviews yet.